Cervical vertebra interbody fusion cage and manufacturing method thereof

A technology of intervertebral fusion device and fusion device, which is applied in the field of intervertebral fusion device, so as to avoid secondary surgical removal and reduce discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

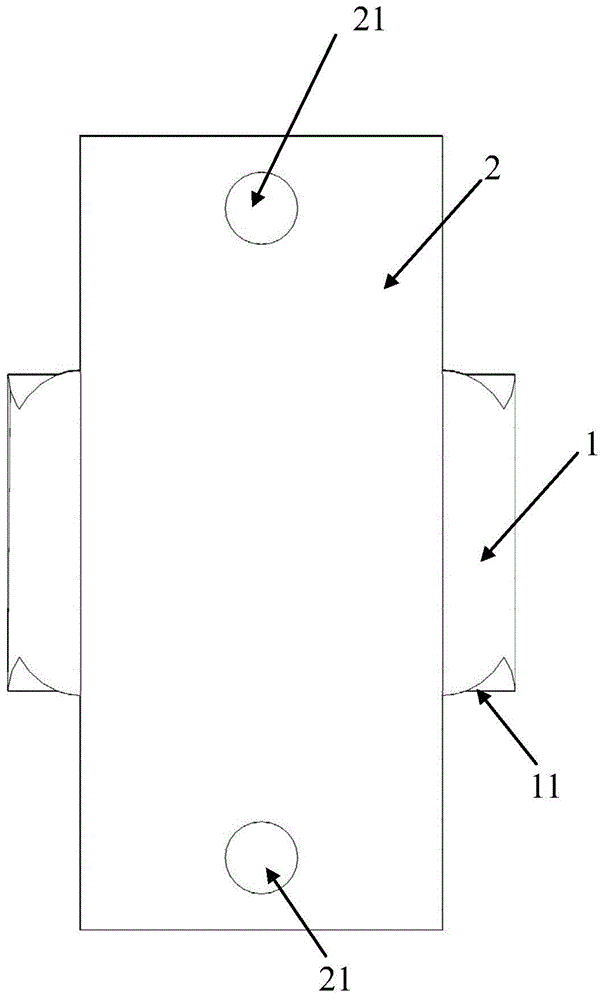

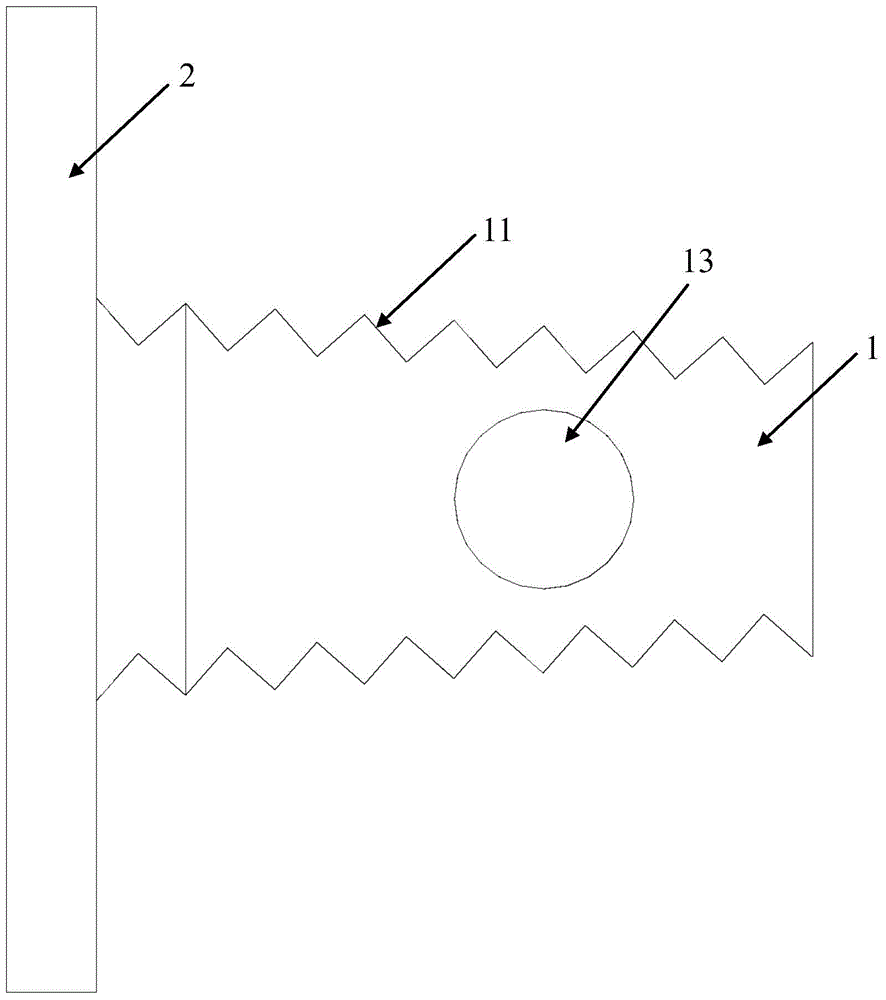

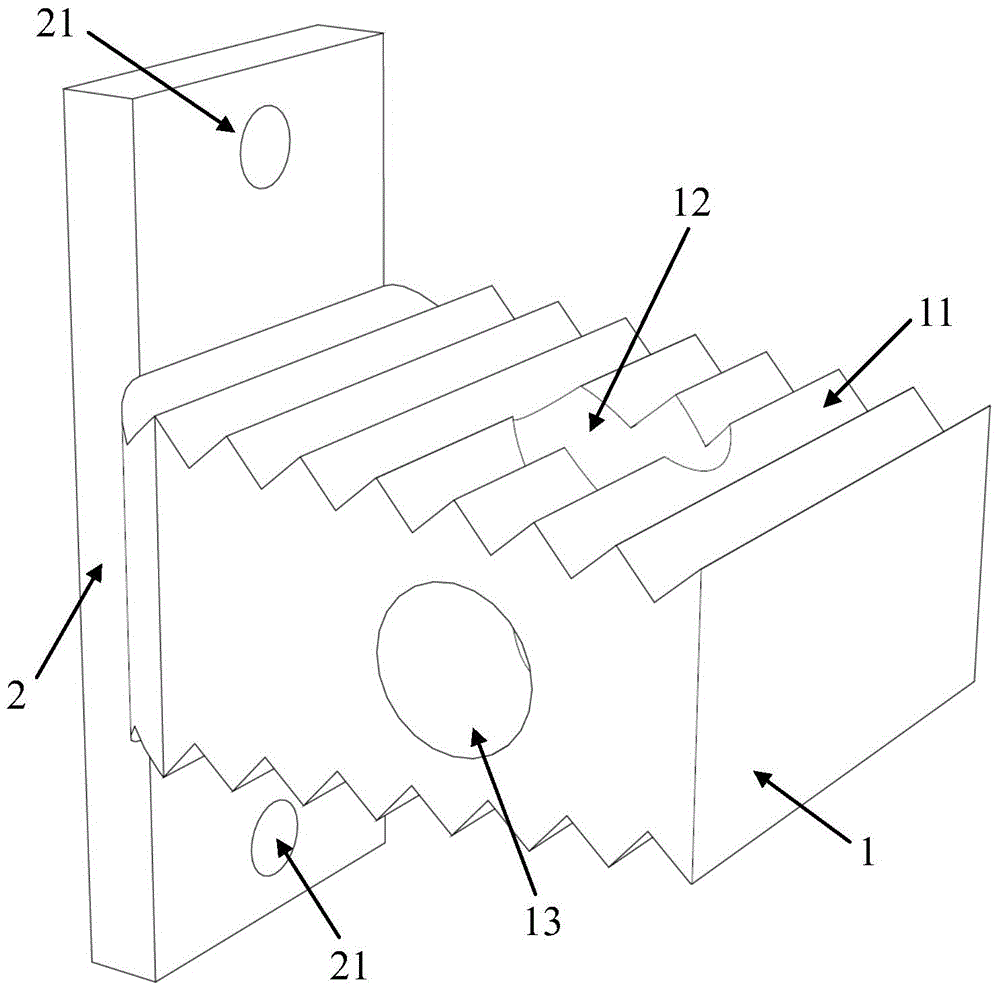

[0067] This embodiment is used to prepare a cervical intervertebral fusion device made of PLA material. Among them, the fuser body 1 is made of pure L-lactic acid (PLLA, with a molecular weight of 800,000) material; the size of the fuser body 1 is 14.0 mm in length, 12.5 mm in width, 7.0 mm in height at the front end, and 6.0 mm in height at the rear end; The upper and lower end surfaces of the fusion device main body 1 have a tooth-like structure with a depth of 0.35 mm and a spacing of 2.0 mm; the left and right sides of the fusion device main body 1 are centered near the rear and have a cylindrical vertical through hole 12 with a diameter of 4.6 mm. The center of the vertical through hole 12 reaches The distance between the rear end surface of the fuser main body 1 is 6.3mm. After testing, the axial compressive strength of the cage body 1 of this embodiment is 110.6 MPa.

[0068] The anterior cervical fixation plate 2 is made of pure racemic polylactic acid (PDLLA, with a ...

Embodiment 2

[0071] This embodiment is used to prepare the cervical intervertebral fusion device of PLA / PCL composite material. Among them, fusion device main body 1 is made of pure PCL (molecular weight: 150,000) material; fusion device main body 1 is 15.0 mm long, 12.0 mm wide, front end height is 8.0 mm, rear end height is 7.0 mm; fusion device main body 1 The upper and lower end surfaces of the fusion device have a tooth-like structure with a depth of 0.5 mm and a spacing of 2.0 mm; the left and right sides of the fusion device body 1 are centered near the back and have a square vertical through hole 12 with a side length of 5.5 mm, and the center of the vertical through hole 12 reaches the fusion device body 1 The distance of the rear end face is 7.0mm. After testing, the axial compressive strength of the cage body 1 of this embodiment is 121.5 MPa.

[0072] The anterior cervical fixation plate 2 is made of pure left-handed polylactic acid (PLLA, with a molecular weight of 200,000); ...

Embodiment 3

[0075] This embodiment is used to prepare the cervical intervertebral fusion device common to the PLGA / β-TCP composite material and the PCL / β-TCP composite material. Among them, the fuser main body 1 is made of PCL / β-TCP composite material (PCL molecular weight is 176,000, β-TCP particle size distribution is 12.0±2.0 μm), PCL / β-TCP=6 / 4(w / w) ; The size of fusion device main body 1 is 16.0 mm in length, 14.0 mm in width, 9.0 mm in height at the front end, and 7.5 mm in height at the rear end; the upper and lower end surfaces of the fusion device body 1 have tooth-like structures with a depth of 0.6 mm and a spacing of 2.2 mm ; There is a cylindrical vertical through hole 12 with a diameter of 6.0 mm in the left and right of the fusion device body 1 near the back, and the distance from the center of the vertical through hole 12 to the rear end surface of the fusion device body 1 is 8.0 mm. After testing, the axial compressive strength of the cage body 1 of this embodiment is 137....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com