Foodstuff stirring machine

A technology of food mixers and mixing barrels, which is applied in mixers, dissolving, chemical instruments and methods, etc., can solve the problems of not being able to determine the best use state of the stirred food, stirring in dead ends, and food odor, etc., and achieves simple structure and improved automation , the effect of mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

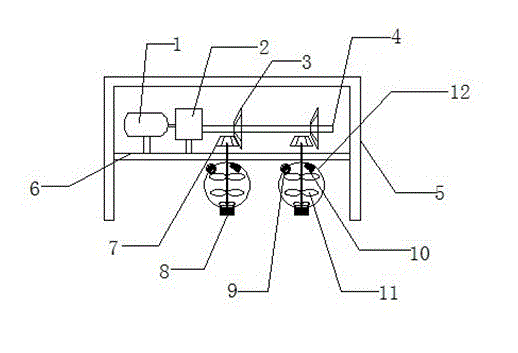

[0015] Such as figure 1 A kind of food mixer shown, comprises mixing tank 12, support 5 and crossbeam 6; Said crossbeam 6 is fixed on the support 5; Said crossbeam 6 is equipped with motor 1; Said motor 1 is connected with speed reducer 2 and transmission Shaft 4; the drive shaft 4 is provided with a driving gear 3; the mixing bucket 12 is movably arranged on the beam 6; the driving gear 3 is connected to the mixing bucket 12 through a driven gear 7; the mixing bucket 12 upper end is provided with The feed port 10 and the intelligent detector 9 are provided with a discharge port 8 at the bottom, and a stirring blade 11 is provided inside.

[0016] Wherein, the mixing bucket 12 is spherical; the mixing blade 11 is provided with one or more layers; the mixing bucket 12 is provided with multiple; the motor 1 is a DC motor.

[0017] The food mixer of the present invention is reasonable in design, low in price, simple in structure, easy to use, safe and efficient, not prone to dea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com