Lateral lug type manual stone grinder

A side-ear type and stone grinding technology, which is applied in the field of stone grinding, can solve the problems of laborious use of manual stone grinding, sparse distribution of grinding teeth, waste, etc., and achieve the effect of avoiding the trouble of cleaning, high distribution density and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

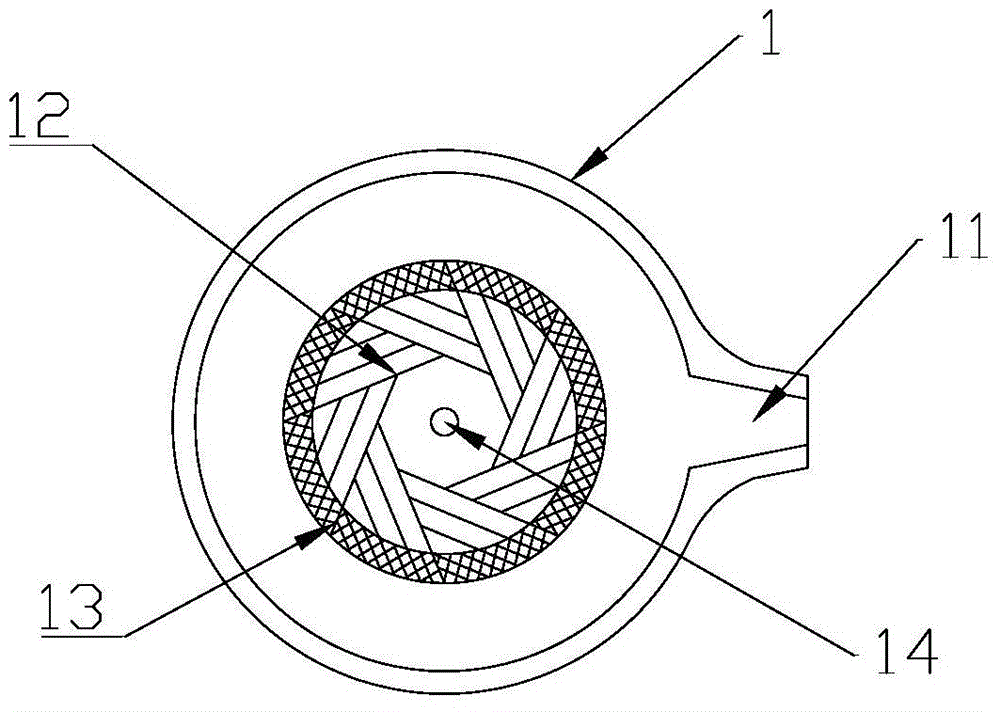

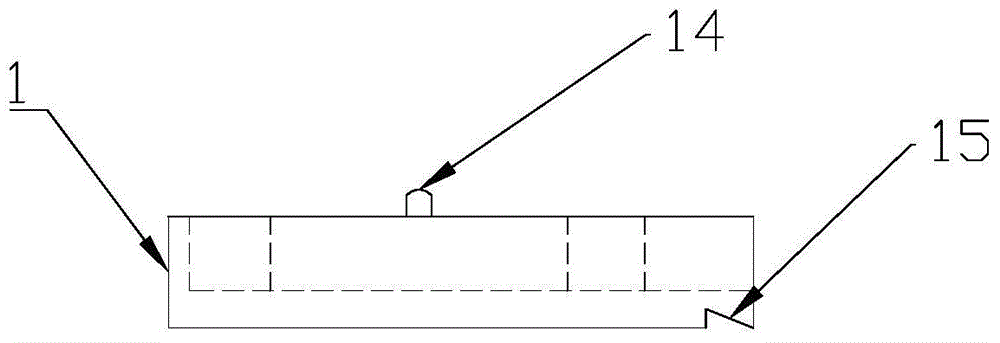

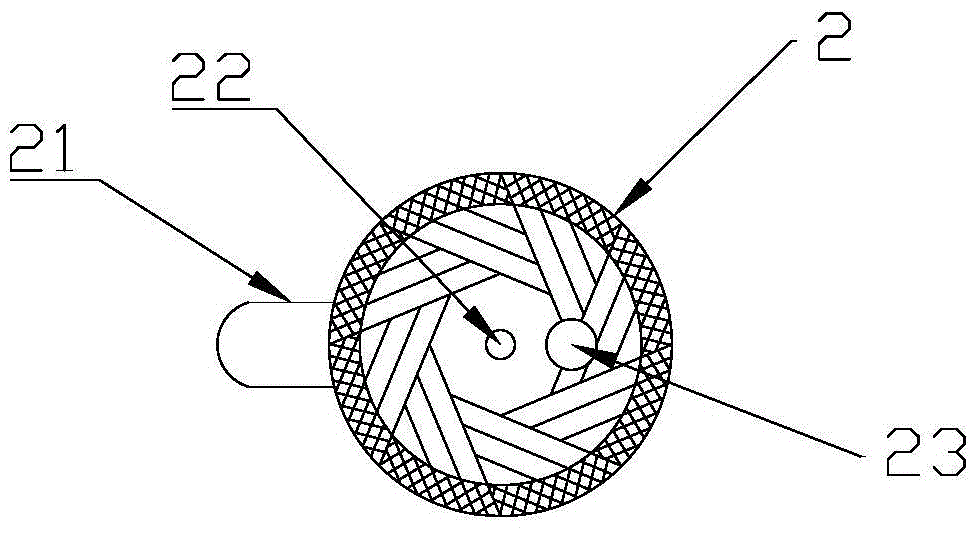

[0032] Such as Figure 1 to Figure 5 As shown, the side-ear type manual stone mill includes an upper mill 2 and a lower mill 1, the center of the lower surface of the upper mill 2 is provided with a central hole 22, and one side of the central hole 22 is provided with a feeding hole 23, and the central hole 22 is Blind hole, the feeding hole 23 is a through hole; the edge of the lower mill 1 is provided with a grinding nozzle 11, and the center of the lower mill 1 is provided with a central shaft 14 matching the central hole 22; the upper mill 2 and the lower mill The mating surface of grinding 1 is provided with grinding teeth,

[0033] One side of the upper mill 2 is provided with a protruding side ear 21, and a vertical lead screw 24 is threadedly connected to the side ear 21. A handle 25 is sleeved on the outside of the lead screw 24, and the handle 25 and the lead screw 24 pass through threaded connection;

[0034] The grinding teeth include main teeth 12 and auxiliary ...

Embodiment 2

[0040] Such as Figure 6 , Figure 7 As shown, the difference between the present embodiment and the first embodiment is that the outer surface of the side wall of the lower mill 1 is arc-shaped and provided with patterns, the smooth transition of the grinding nozzle 11 forms a sharp corner, and the upper end surface of the grinding nozzle 11 for the inclined surface.

[0041] In this embodiment, the design of the lower grinder and the grinding mouth is more beautiful and has a classical charm.

[0042] Regarding the distribution of grinding teeth in the above embodiments, according to the law of dividing the entire grinding disc into eighths, tenths, twelveths... and so on, it can only be an even number, not an odd number.

[0043] Below in conjunction with a working process, the present invention will be further described:

[0044] Assemble the upper mill 2 and the lower mill 1 so that the central shaft 14 is inserted into the central hole 22, and the material will fall i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com