Single-station rotating cleaning machine for automobile air conditioning compressor

A technology for automotive air conditioners and compressors, applied in cleaning methods and appliances, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve the problems of unfavorable customers' maximum utilization of factory space, etc., and achieve compact structure and economical use The effect of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

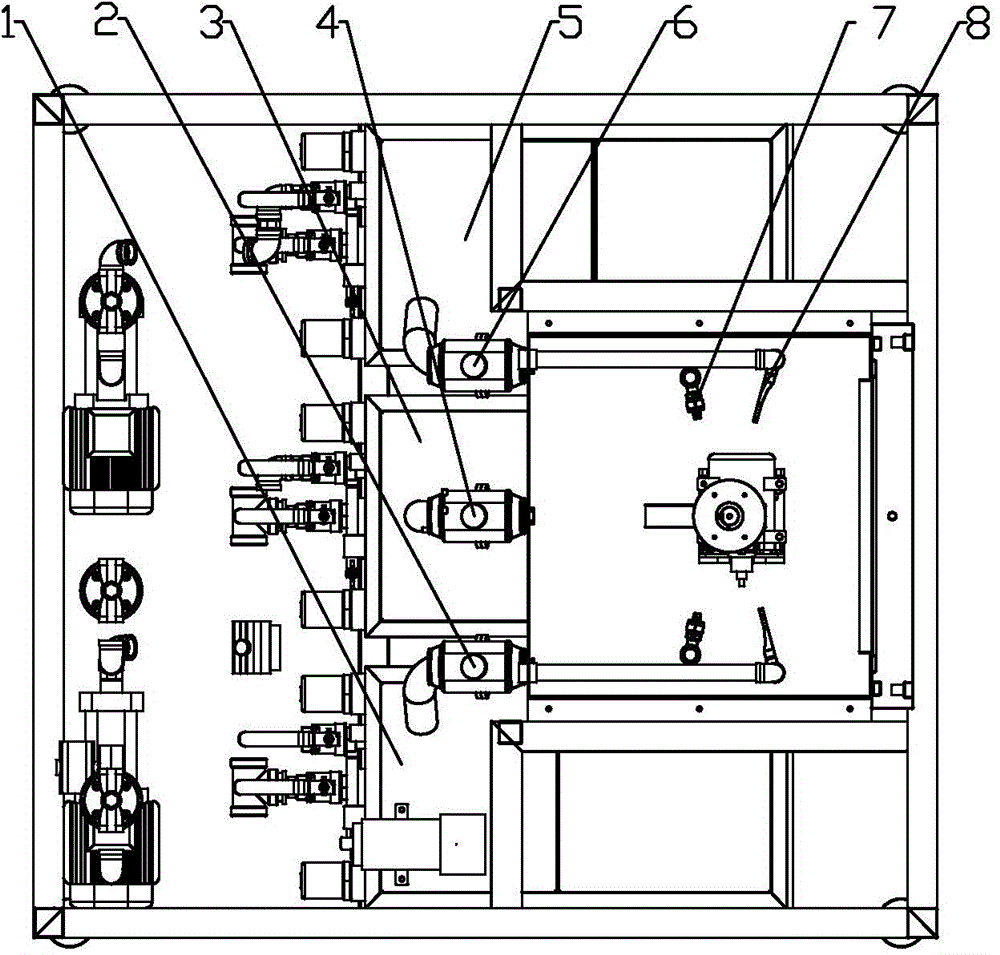

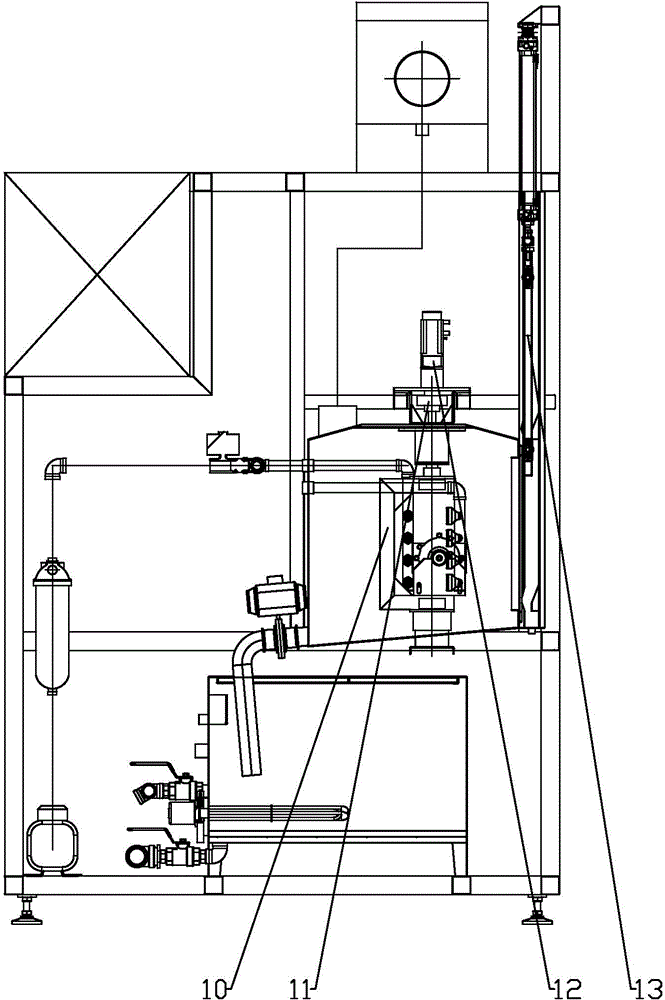

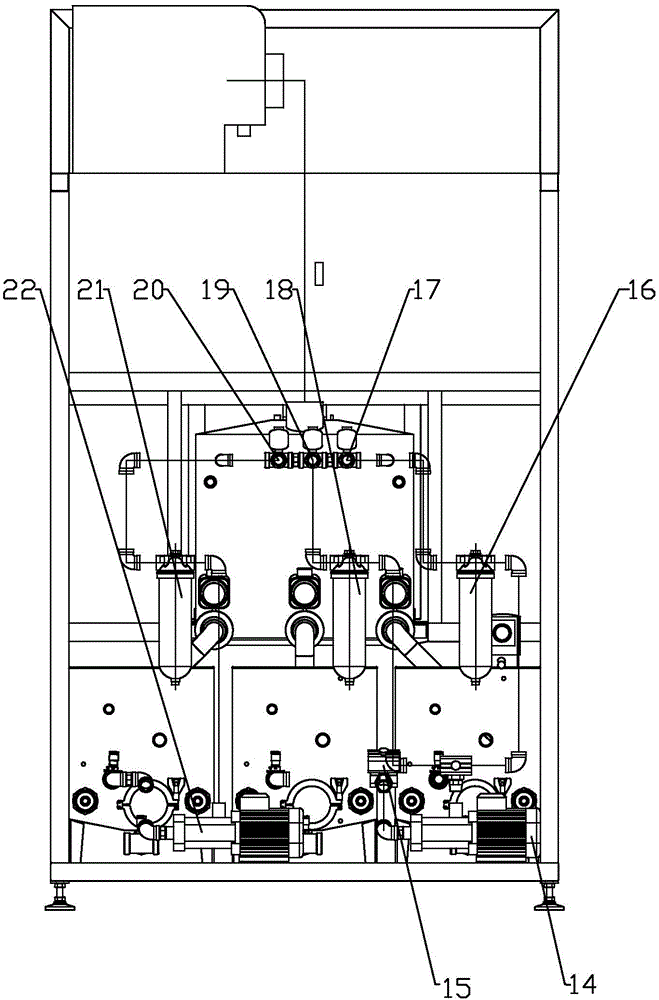

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0031] refer to Figures 1 to 3 , the automotive air-conditioning compressor single-station rotary cleaning machine provided by the present invention comprises a frame, and the frame is provided with a lifting sealing door 13, a workpiece rotation mechanism, a spray mechanism corresponding to the workpiece rotation mechanism and a compressed air wind shear mechanism;

[0032] The workpiece rotation mechanism includes a rotary motor 12 arranged on the frame, and a rotary frame 10 driven by the rotary motor 12 through a coupling 11;

[0033] The spray mechanism comprises a liquid storage tank, a spray pump communicated with the outlet of the liquid storage tank, a spray filter communicated with the outlet of the spray pump, and a spray pipe 7 communicated with the spray filter, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap