Machining method for incrementally forming complex part through engineering tailor-welded blanks

A technology of incremental forming and complex parts, applied in the field of machining, it can solve the problems of complex internal stress, difficulty in guaranteeing the quality of welds, mechanical and mechanical properties such as strength and stiffness that cannot meet the requirements of parts, etc. Stiffness, avoid welding seam offset, make up for the effect of material thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

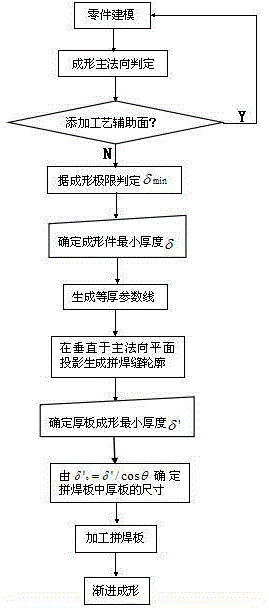

[0030] figure 1 It is a process flow diagram of the present invention.

[0031] like figure 1 Shown: The processing method of using tailor-welded blanks to realize the incremental forming of complex parts, the specific steps are:

[0032] (1) Establish a three-dimensional model of the part and determine the direction of the main normal line of the part;

[0033] (2) Judging whether it is necessary to add a process auxiliary surface, if it needs to be added, first add a process auxiliary surface, then enter step (1), and then enter step (3), if no addition is required, then directly enter step (3);

[0034] The steps of adding the process auxiliary surface are specifically:

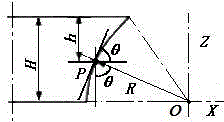

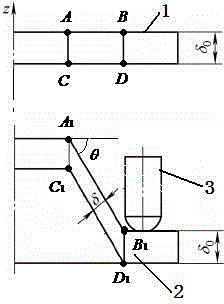

[0035] ①Take plane A along the direction perpendicular to the main normal of the part. The plane A is located below the part during progressive positive forming and above the part during progressive negative forming. The vertical distance between the plane and the lowest or highest point of the part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com