Combined type continuous casting blank surface temperature measurement method and instrument

A surface temperature measurement and composite technology, which is applied in the direction of casting equipment, indicating equipment/measuring equipment configuration, manufacturing tools, etc., can solve problems such as unavoidable measurement errors and emissivity inconsistencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

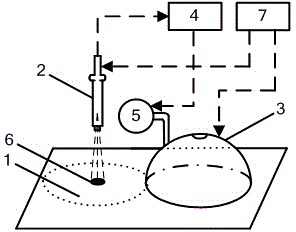

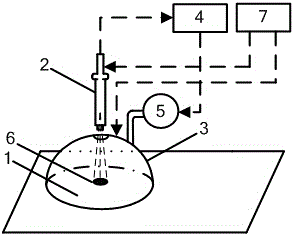

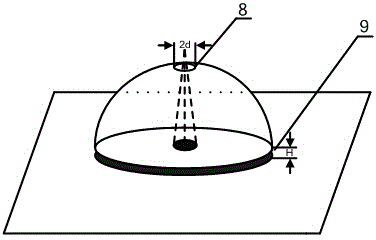

[0040]The composite continuous casting slab surface thermometer includes a reflector 3, a motor drive mechanism 5, an infrared temperature detector 2, a calculation and control system unit 4 and a cooling system 7; the reflector 3 is driven by the calculation and control unit 4 through a motor The structure 5 controls the rotation; the electrical signal output end of the infrared temperature measuring detector 2 is connected to the electrical signal input end of the calculation and control unit 4; the infrared temperature measuring detector 2 and the reflector 3 are connected to the cooling system 7 respectively.

[0041] The compound continuous casting slab surface temperature measurement method establishes a dual-wavelength temperature measurement equation under the conditions of no reflector measurement and reflector measurement. In the reflectorless measurement process (such as figure 1 As shown), the temperature measuring detector directly receives the radiant energy of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com