A process for improving the performance of large-diameter carbon steel cast-rolled flanges

A process method and large-diameter technology, applied in the direction of metal rolling, can solve the problems of coarse grains, the mechanical properties of flanges are difficult to meet the requirements of industrial use, etc., and achieve the effect of strong competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

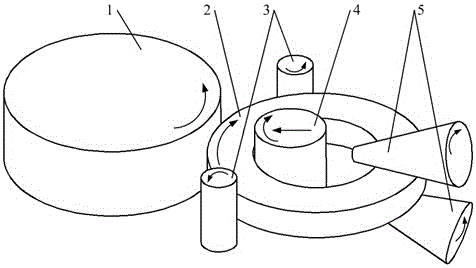

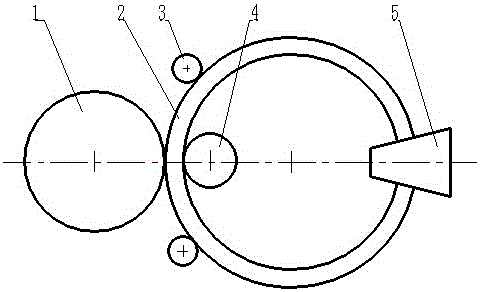

[0022] Such as figure 1 The cast ring of material Q345B shown has an outer diameter of 740mm, an inner diameter of 380mm, and a height of 185mm. It is formed by controlled rolling and controlled cold rolling through a ring diameter-axial rolling machine to reach an outer diameter of 1550mm, an inner diameter of 1306mm, and a height of 105mm. Its process steps are:

[0023] ①Heating the casting ring in the ring heating furnace: the temperature in the preheating section is 900°C, and the heating time is 90 minutes; → the temperature in the heating section is 1250°C, and the heating time is 120 minutes;

[0024] ②Remove phosphorus by spraying high-pressure water to the entire ring billet: water temperature 20°C, water pressure 15MPa, flow rate 50m 3 / h, spray distance 150mm, spray angle 20°, ring billet temperature after high pressure water descaling is 1050°C;

[0025] ③Put the dephosphorized ring blank into the CNC ring rolling machine for hole reaming, the core roller 4 rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com