Magnetic type clamp for electric spark machining

A kind of electric spark and magnetic suction technology, applied in electric processing equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of inconvenient clamping and positioning, affecting processing, different workpiece shapes, etc., to achieve good clamping effect, The effect of avoiding limitations and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

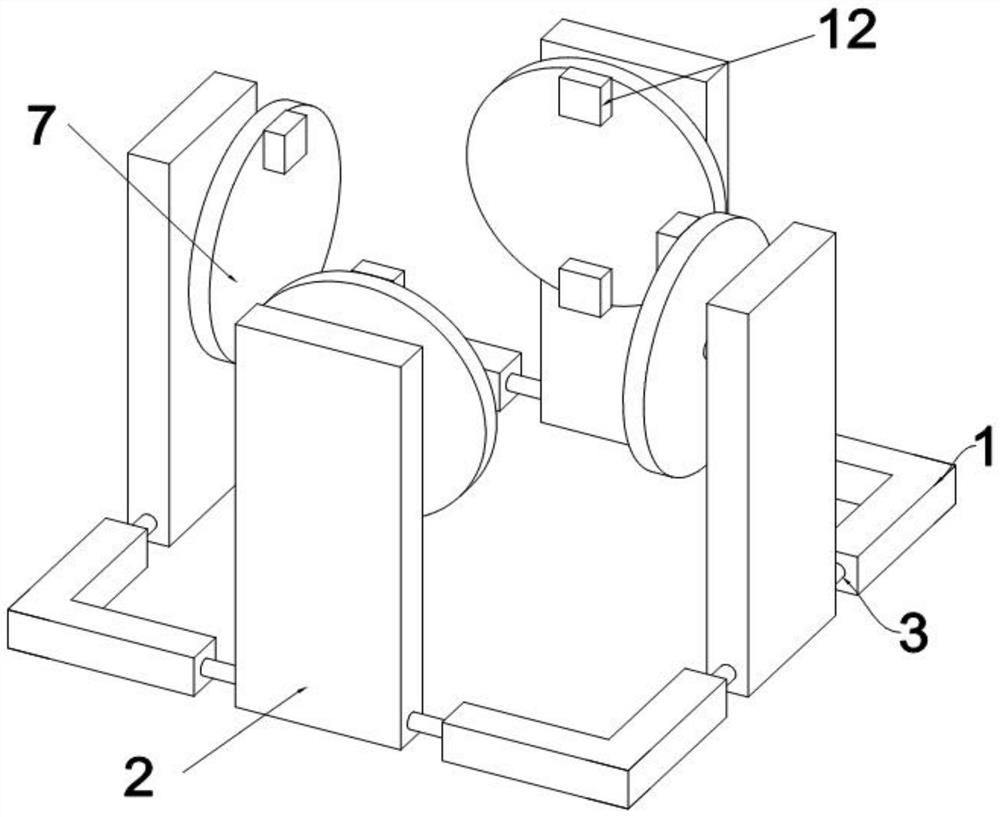

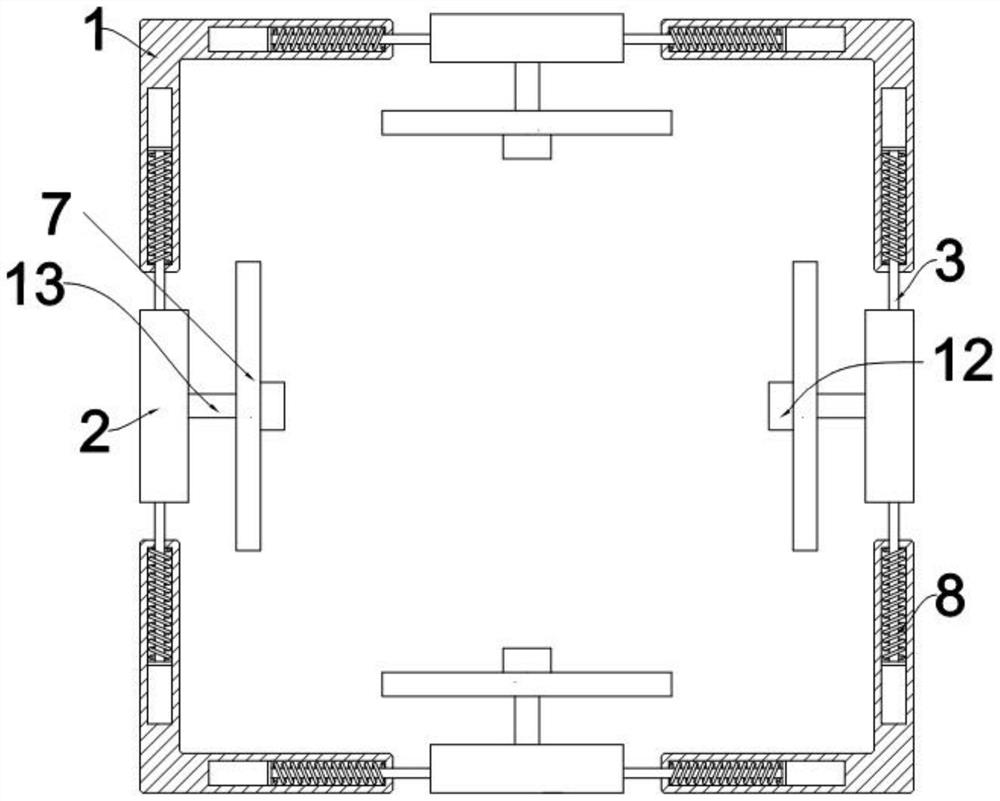

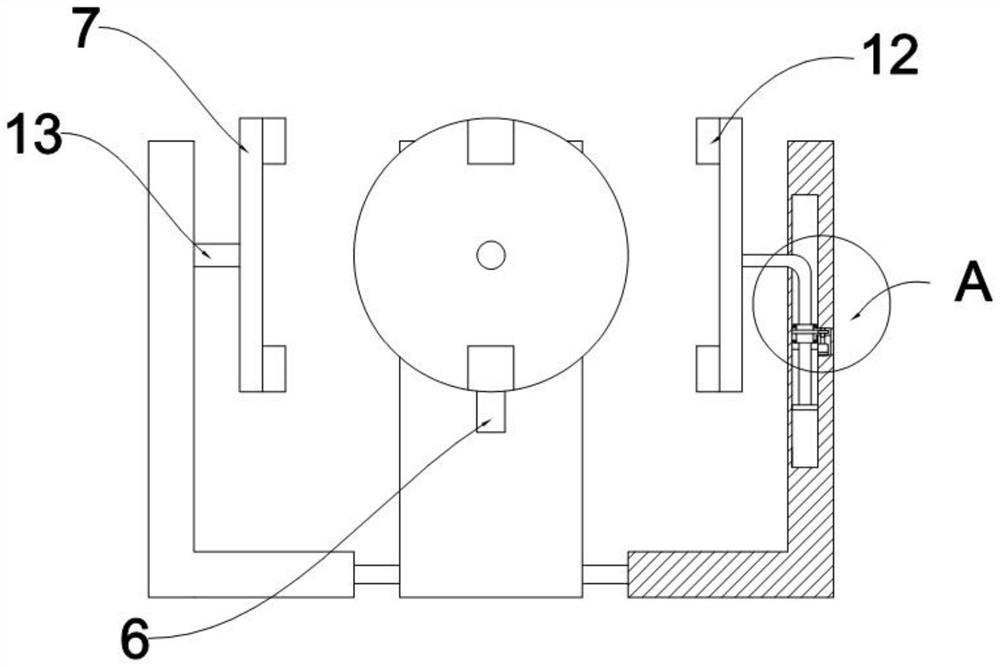

[0025] see Figure 1 to Figure 4, an embodiment provided by the present invention: a magnetic suction electric discharge machining fixture that can match parts with different shapes, including four L-shaped base connecting rods 1, and the L-shaped base connecting rods 1 and adjacent L-shaped bases An electromagnet support plate 2 is arranged between the end and the end of the connecting rod 1, and there are 4 electromagnet support plates 2, and the 4 electromagnet support plates 2 are distributed in a circular array along the vertical center axis of the device. This distribution method makes The fixture has an acting force on the x-axis and y-axis of the workpiece, a...

no. 2 example

[0031] Based on the magnetic suction type electric discharge machining fixture provided by the first embodiment that can match parts with different shapes, only the clamping operation of the electric discharge machining fixture is realized, but in the actual application process, all surfaces need to be When performing electric discharge machining, it is necessary to perform multiple clamping operations again. Performing clamping operations in the electrolyte solution after EDM not only reduces work efficiency, but also has certain safety hazards. In order to avoid multiple clamping operations With the appearance of the clamping operation, the adjustment operation of the processing surface can be realized during the processing, refer to Figure 1-4 , a magnetic suction type electric discharge machining fixture that can match parts with different shapes also includes an angle sensor fixed inside the elastic splint 7, and the angle sensor is used to detect the relative rotation an...

no. 3 example

[0035] Based on the second embodiment, a magnetic suction EDM fixture that can match parts with different shapes is provided, which only realizes the automatic clamping process for all surface machining during EDM, but in the actual machining process, sometimes It only needs to process any number of surfaces, and there is no fixed angle relationship between several surfaces. At this time, if one surface is clamped one by one, not only the work efficiency will be slow, but also multiple clamping will cause damage to the workpiece. In order to avoid For multiple clamping, the following operations can also be performed in conjunction with the machine tool terminal control system and fixtures:

[0036] After one processing surface of the workpiece is processed, when another specific surface to be processed needs to be processed, similar to the second embodiment, the X surface and the Y surface are preferentially determined, and the Z surface is the moving surface in the vertical di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com