Plate forming machine for insulation engineering construction and plate forming method thereof

A technology for engineering construction and molding machines, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of poor quality, a lot of manpower, low efficiency, etc., to achieve the effect of improving appearance quality, good molding quality, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific examples.

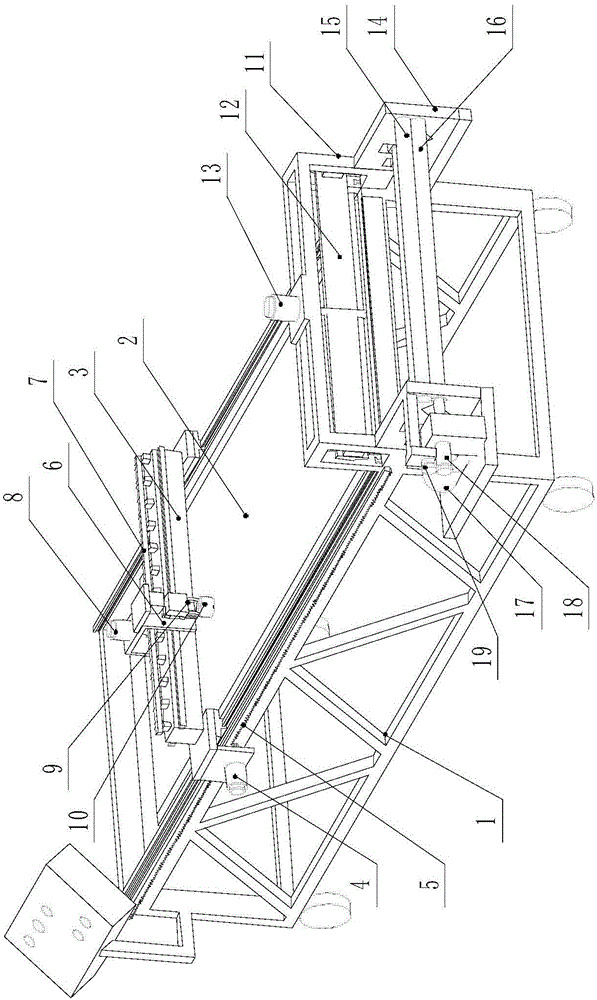

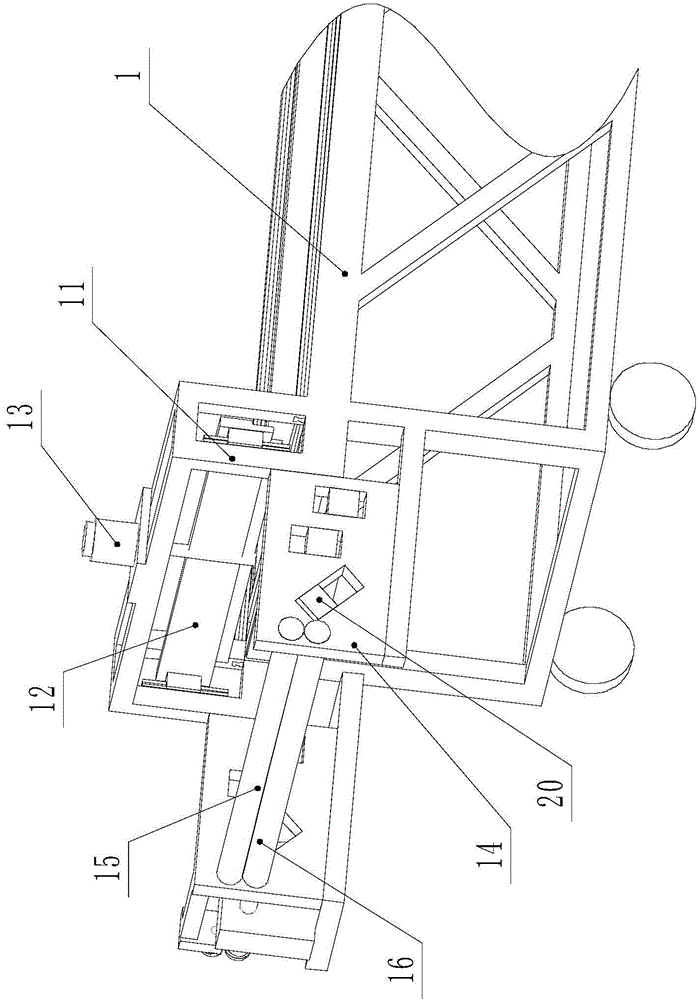

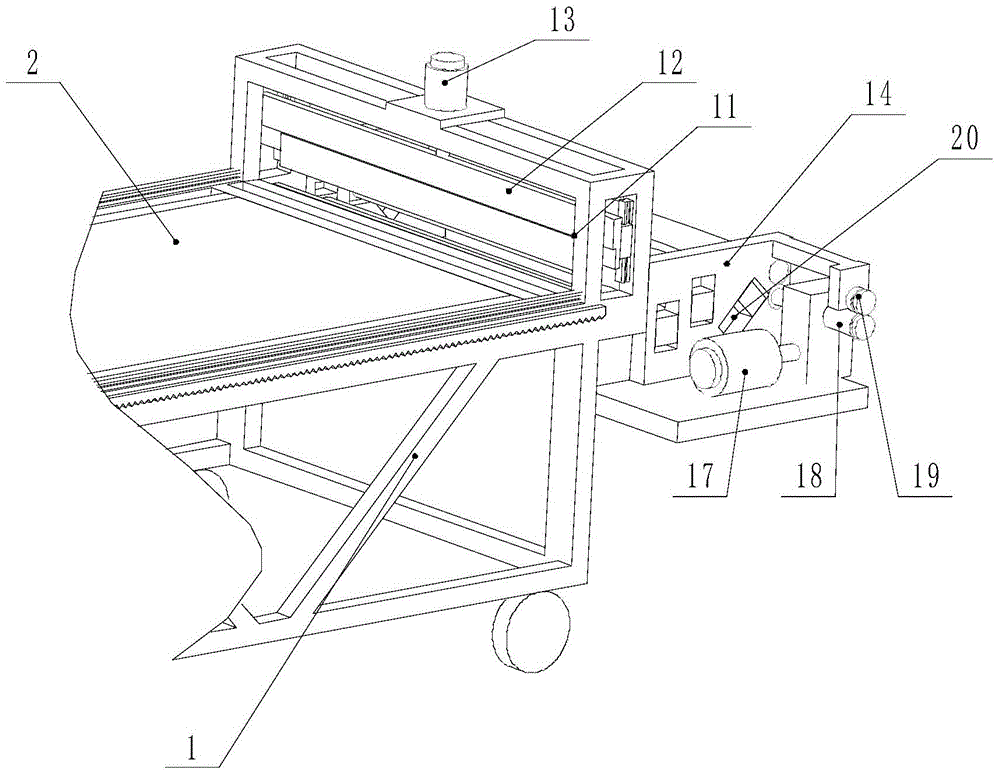

[0033] Such as figure 1 , 2 , Shown in 3, a kind of molding machine of insulation engineering construction plate, comprises frame 1, transverse cutting device, sliding cutting device, leveling feeding mechanism.

[0034] The frame 1 is provided with a working platform 2, and the upstream end of the frame 1 is fixed with a leveling and feeding mechanism, and the leveling and feeding mechanism will level the plate and send it to the working platform 2; the bottom of the frame 1 is provided with The rollers are convenient for the whole frame 1 to move. The leveling and feeding mechanism includes two feeding shafts that cooperate with each other and three leveling shafts. The two feeding shafts are rotatably mounted on the frame 1 and arranged in parallel up and down in the horizontal direction, such as figure 2As shown, the feeding shaft at the upper end is the upper feeding sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com