Automatic roll discharging and core feeding device and automatic roll discharging and core feeding method

An automatic unloading and rewinding shaft technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of long time consumption, high labor intensity of workers, and low degree of automation, so as to reduce labor intensity and structure Simple and ingenious, highly customized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

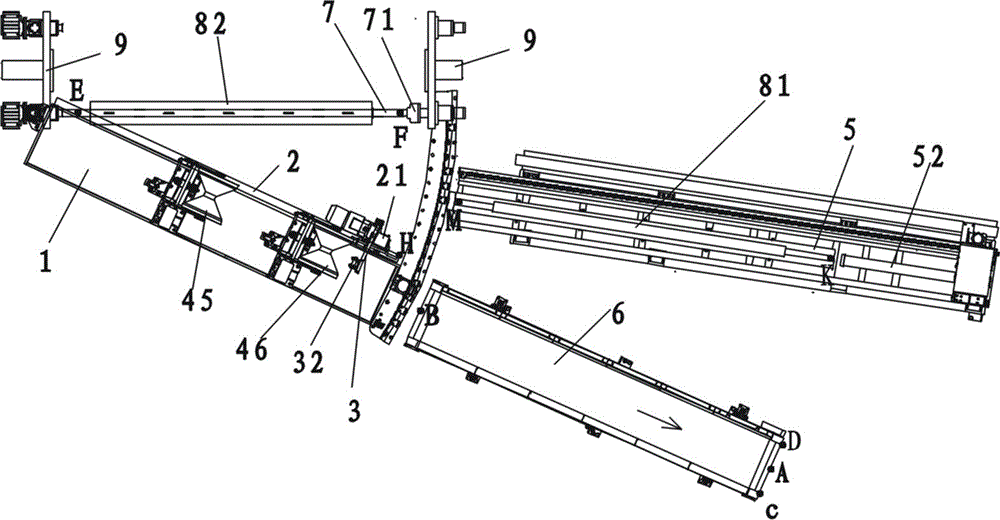

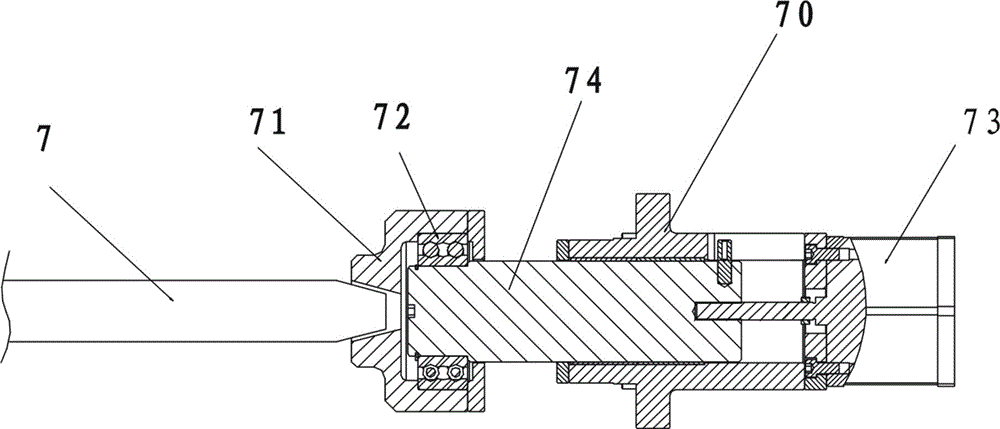

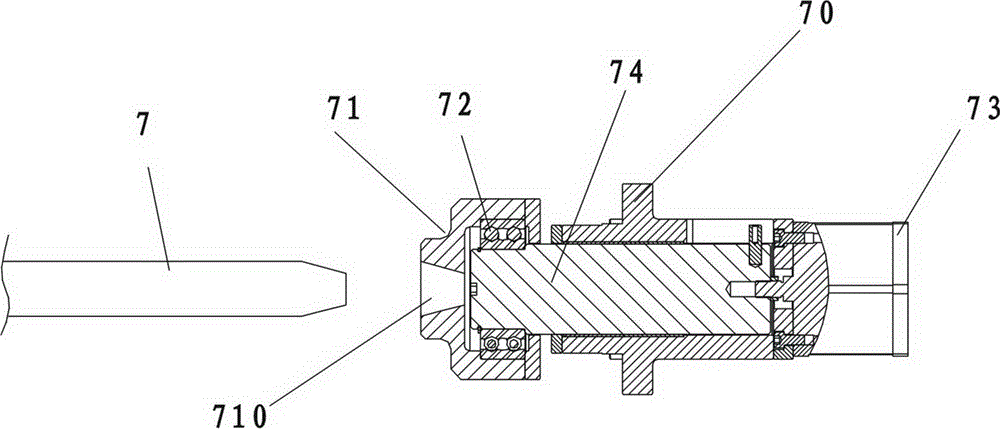

[0061] figure 1 As shown, the automatic unwinding core device includes a frame 9, a rewinding shaft 7, two ends of the rewinding shaft 7 are provided with a rewinding shaft support 70, 75, and the rewinding shaft 7 is rotatably (autorotated) mounted on the rewinding shaft support . figure 1 , figure 2 , image 3 Shown, wherein the first winding shaft support 70 ( figure 1 The support on the right side of the middle) is provided with a shaft sleeve 71, the inner cavity 710 of the shaft sleeve has a taper, the shaft sleeve 71 is axially movable and installed on the frame, and the winding shaft end on the same side as the shaft sleeve 71 department( figure 1 middle right end) is also provided with a corresponding taper; the frame is also provided with a shaft sleeve driving mechanism that drives the shaft sleeve to move axially. Telescopic link 74, telescopic link 74 and axle sleeve 71 are axially fixedly connected together by bearing 72, and telescopic link 74 and axle sle...

Embodiment 2

[0073] An automatic unwinding and coreing method, which adopts the automatic unloading and coreing device of the first embodiment, and includes the following steps in sequence: (1), the winding shaft 7 drives the paper core to rotate, and the plastic film is wound up to implement normal winding; roll to form a film volume 82; during normal winding, the winding shaft 7 is in the winding position, such as figure 1 As shown, the sliding support 21 is located at the far-center end of the swing support 1. From the horizontal projection position, the horizontal guide rail 2 is at a position forming a horizontal angle of 30° with the central axis of the winding shaft; Spare paper core tube 81; two support roller bearings 41 are in the low position of its vertical movement stroke (that is, the middle and lower part of vertical guide rail 42), the end of the swing arm and the small roller are in the low position of its swing stroke around the swing arm swing shaft 30, like figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com