A new type of slewing support device for pile-wound crane

A technology of slewing bearings and cranes, which is applied in the direction of cranes, etc., can solve the problems of large design of slewing shafts and bushings, difficulty in maintenance and overhaul, and increased manufacturing costs, and achieve the effects of simple appearance, low cost, compact and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

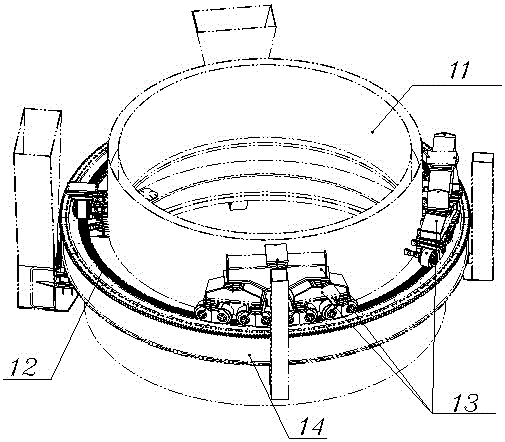

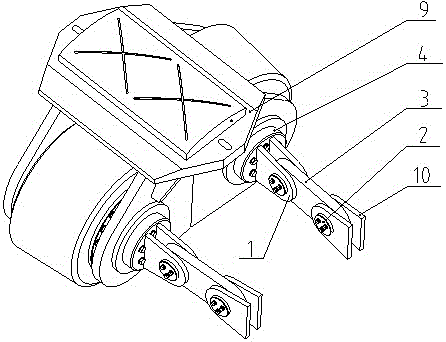

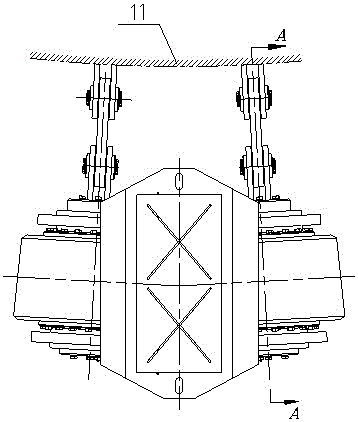

[0016] A specific embodiment of a new type of slewing support device for a pile-wrapping crane according to the present invention, such as figure 1 The shown slewing support device includes multiple sets of wheel sets, such as Figure 2 to Figure 4 Each set of wheel groups shown includes a wheel group bracket 9 and two wheels 6, and the two wheels 6 are installed inside the wheel group bracket 9 through two wheel shafts 5. Between each wheel 6 and the wheel shaft 5, two adjustment The core roller bearing 8 is assembled, the end of the wheel shaft 5 away from the rotating center cylinder 11 is fixed with the gland 7, and the end close to the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com