Bragg grating temperature self-compensation pressure sensor on fiber cladding surface

A technology of pressure sensor and optical fiber cladding, applied in the direction of fluid pressure measurement, measuring fluid pressure, instruments, etc. by optical methods, can solve the problems of low pressure sensitivity of bare FBG, increase the number and size of sensors, and achieve the goal of not being prone to electromagnetic interference , Improved accuracy, high accuracy and sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

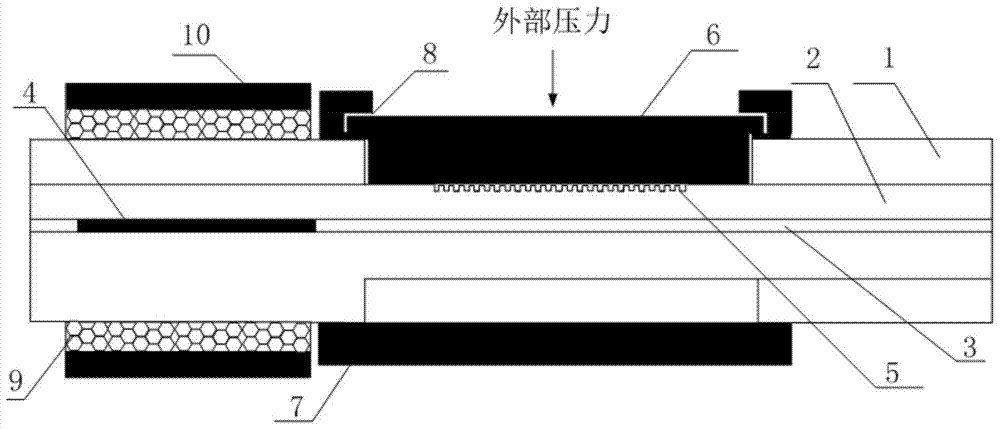

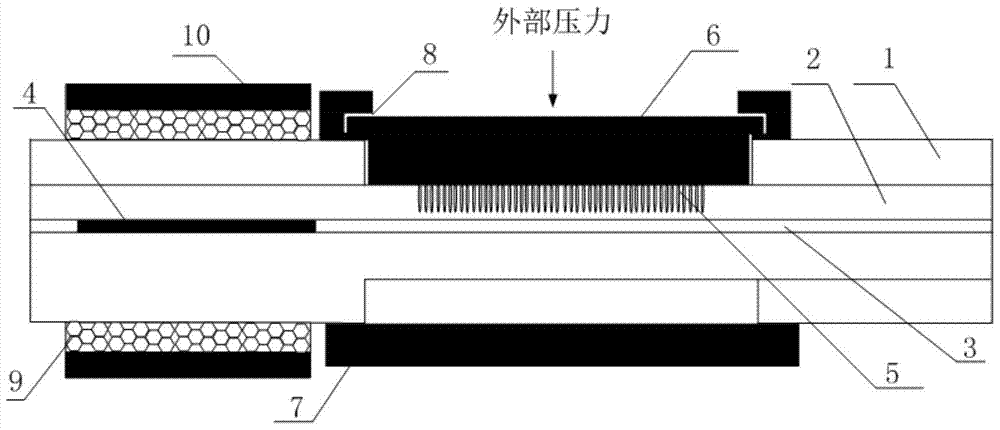

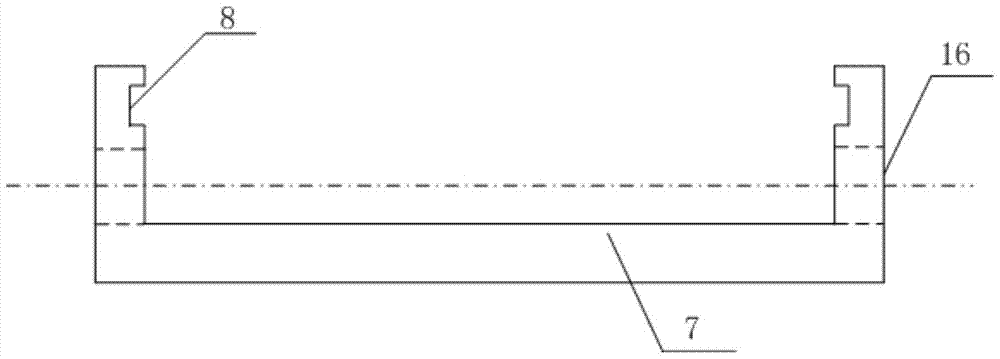

[0021] see figure 1 , figure 2 and image 3 , a temperature self-compensating pressure sensor with a Bragg grating on the surface of the fiber cladding, comprising an optical fiber core 3 and an optical fiber cladding 2 wrapping the optical fiber core 3 and a metal disc 7, the front section of the optical fiber core 3 is provided with a long-period fiber grating 4, The long-period fiber grating 4 is used as an optical resonant coupler for the fiber core and the cladding; the fiber cladding surface Bragg grating 5 is set on the outer surface of the fiber cladding 2 corresponding to the middle section of the optical fiber, and the fiber cladding surface Bragg grating 5 is composed of several Periodic linear grooves parallel to each other are formed or the Bragg grating 5 on the surface of the fiber cladding is formed of several point-like grooves or formed of several linear grooves parallel to each other; the linear grooves or The point-shaped grooves are distributed periodic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com