Steel wire rope protector and engineering machinery

A protection device, engineering machinery technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of shortening the service life of the wire rope, destroying the surface of the wire rope, increasing the adhesion, etc., and achieving the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Various preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

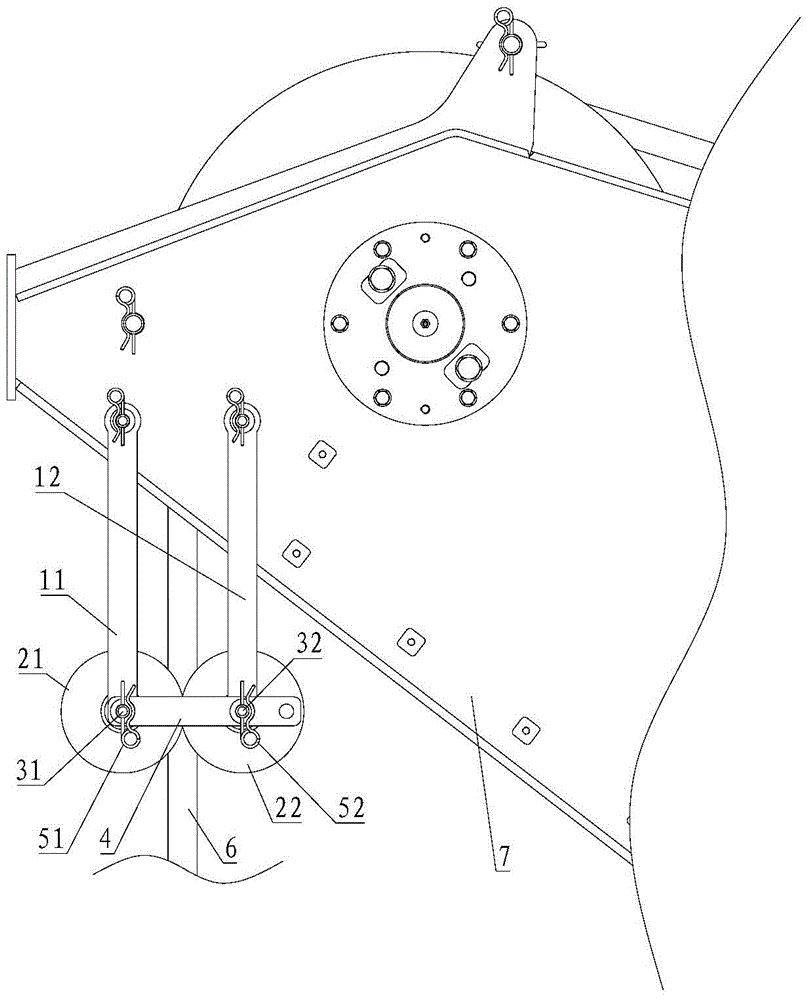

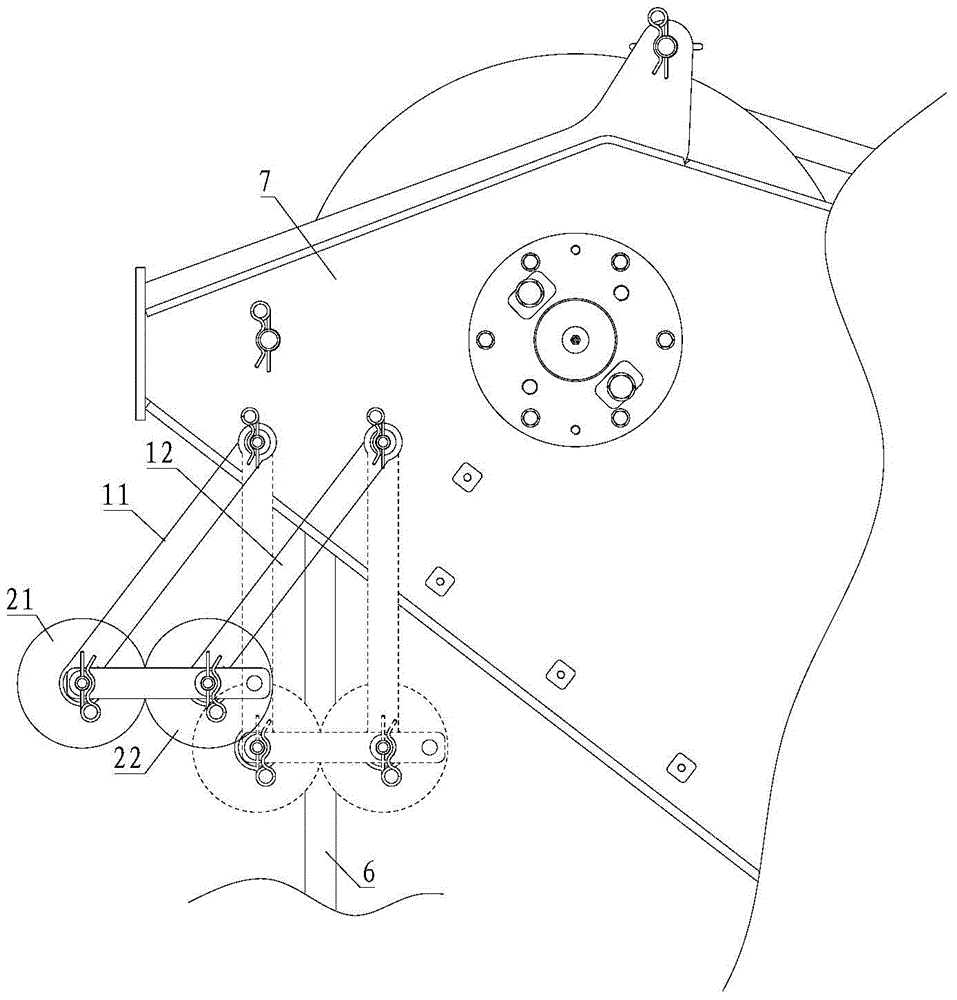

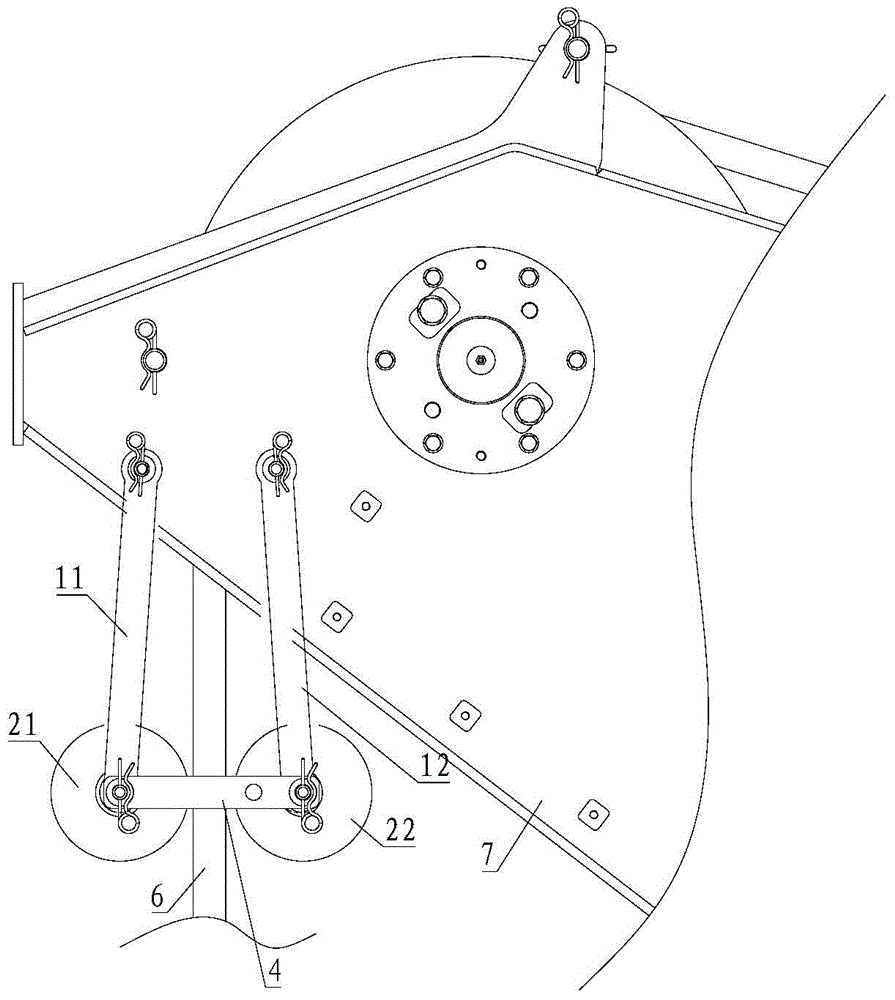

[0029] See figure 1 , which shows the structure of the wire rope protection device provided by the embodiment of the present invention. The wire rope protection device specifically includes:

[0030] A strut assembly, which includes a first strut 11 and a second strut 12;

[0031] The roller assembly includes a first roller 21 , a second roller 22 , a first connecting shaft 31 and a second connecting shaft 32 . in,

[0032] The first roller 21 is rotatably sleeved on the first connecting shaft 31, and the first connecting shaft 31 is connected to the first pole 12; the second roller 22 is rotatably sleeved on the second connecting shaft 32, and the second connecting shaft ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap