A kind of ignition method of ammonia oxidation method to produce nitric acid

A technology of ammonia oxidation and nitric acid, applied in the direction of nitrogen oxides/oxyacids, nitric acid, etc., can solve the problems of low operator skills, lack of ignition conditions, environmental pollution, etc., to avoid air pollution and shorten driving time , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

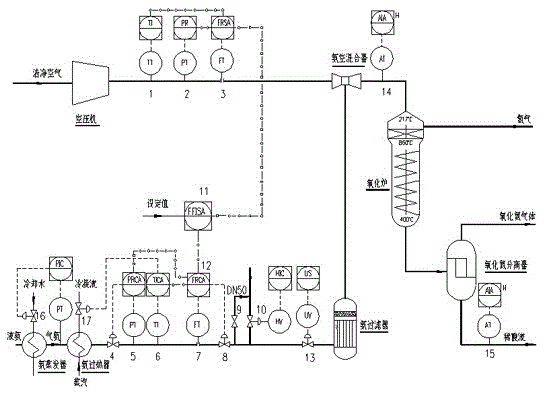

[0043] 1. Installation of ignition equipment

[0044] (1) Connect the air compressor to the ammonia-air mixer through the air pipeline, install air flow temperature compensation 1, air flow pressure compensation 2 and air flow meter 3, air flow temperature compensation 1 and air flow pressure compensation 2 in the air pipeline The output ends of the air flow meter are respectively connected to the input ends of the air flow meter 3, and the output ends of the air flow meter 3 are connected to the input ends of the ratio regulator 11;

[0045] (2) Connect the ammonia superheater to the ammonia filter through the ammonia gas pipeline, and then connect it to the ammonia-air mixer. Install the gas ammonia pressure regulating valve B4 from the ammonia gas pipeline at one end of the ammonia superheater, and the gas ammonia flow pressure compensation is 5 , gas ammonia flow temperature supplement 6, gas ammonia flow meter 7, gas ammonia flow regulating valve 8 and emergency shut-off ...

Embodiment 2

[0070] The DCS sets the automatic gradual change mode of the gas ammonia flow regulating valve 8 to make the ammonia / air ratio reach 8.5% molar content within 2.5 minutes, and the molar content ratio rises from 0% to 7% in the first 1.5 minutes, and then in the next 1 minute Within 5 minutes, the molar content rose to 8.5% from 7%, and then the ammonia / air ratio was adjusted to 9.5% molar content in 5 minutes. All the other were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com