A kind of bauxite frit and preparation method thereof

A technology of bauxite and frit, which is applied in the field of high-temperature structural materials, can solve the problems of reduced slag resistance, unstable volume, and low bulk density, and achieve the effects of simplifying the production process, improving production efficiency, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

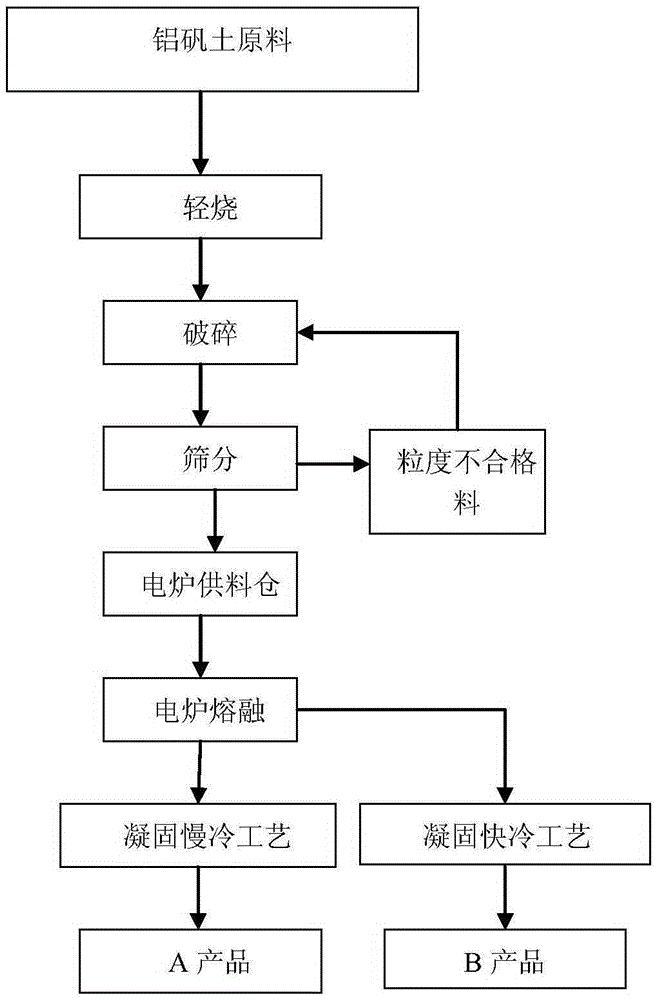

[0032] Embodiment 1: The electric furnace used in this embodiment is a dumping furnace, the rated power of the electric furnace is 22500KW, and the rated capacity of the electric furnace is 20 tons. refer to figure 1 , the preparation process of this embodiment is:

[0033]Step 1: Lightly burn the preferred bauxite raw material in a shaft kiln at 1020°C until the dehydration rate of the raw material is greater than 99.5%. The raw material after light burning is crushed by a jaw crusher, passed through a 15mm sieve, and the bauxite after light burning is detected The chemical composition of raw materials is (wt%): SiO 2 : 2.28, Al 2 o 3 : 92.04, Fe 2 o 3 : 0.51, CaO: 0.18, MgO: 0.14, K 2 O: 0.10, Na 2 O: 0.02, TiO 2 : 4.10, burning reduction: 0.63;

[0034] Step 2: Put the crushed light burnt material into the electric furnace without adding any additives for smelting. Arc carbon rod, the electrode is lowered and connected to the arc starting carbon rod, and then add ...

Embodiment 2

[0039] Embodiment 2: The electric furnace used in this embodiment is a dumping furnace, the rated power of the electric furnace is 22500KW, and the rated capacity of the electric furnace is 20 tons.

[0040] refer to figure 1 , the difference between this embodiment and Embodiment 1 is:

[0041] Step 3: After the smelting is completed, pour the melt in the electric furnace onto the condensing pan. The lower part of the condensing pan has a water-cooled tube. The capacity of the condensing pan is 16 tons (referring to the melt carrying capacity). Above 50°C, the flow rate of water in the water-cooling tube is not less than 3t / h, the cooling cycle is 18 hours, and the surface temperature of the frit is 800°C after 5 hours and 50 minutes, which prevents the decomposition of aluminum titanate (aluminum titanate is at 800-1280°C decompose in the temperature range).

[0042] According to the B product prepared by the process of Example 2, its physical and chemical indicators detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com