Composition for padding of polyurethane boxing gloves and its preparation method

A filler, polyurethane technology, applied in the field of polyurethane materials, can solve the problems of boxer injury, inconvenience to carry, heavy weight of boxing gloves, etc., to achieve the effect of safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

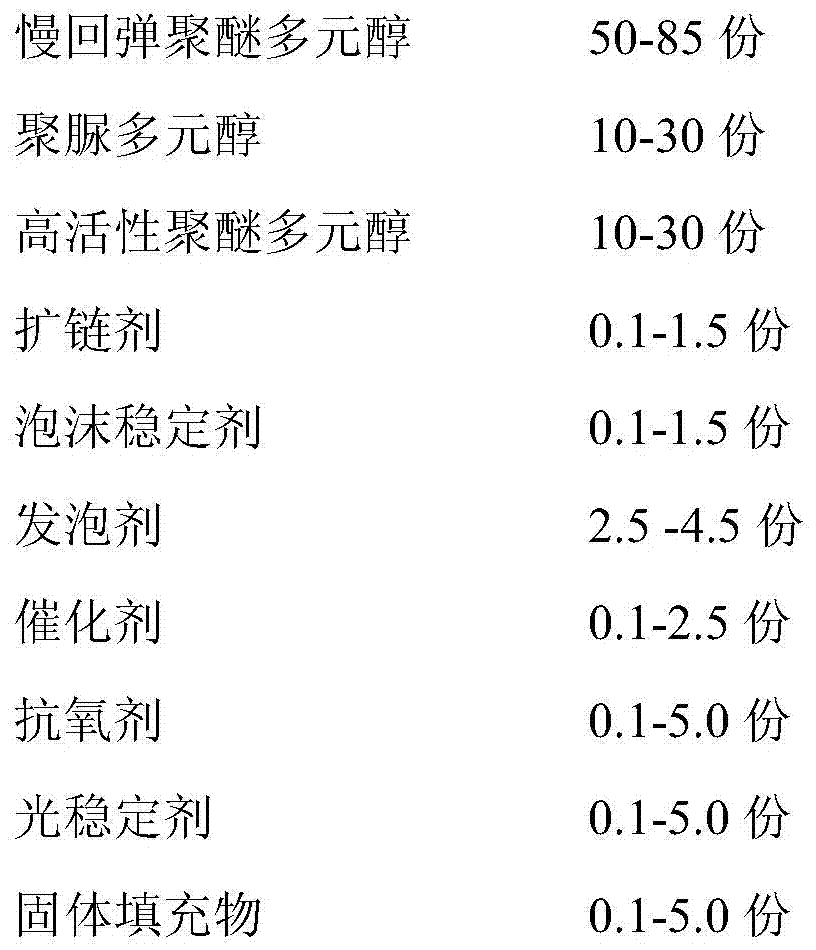

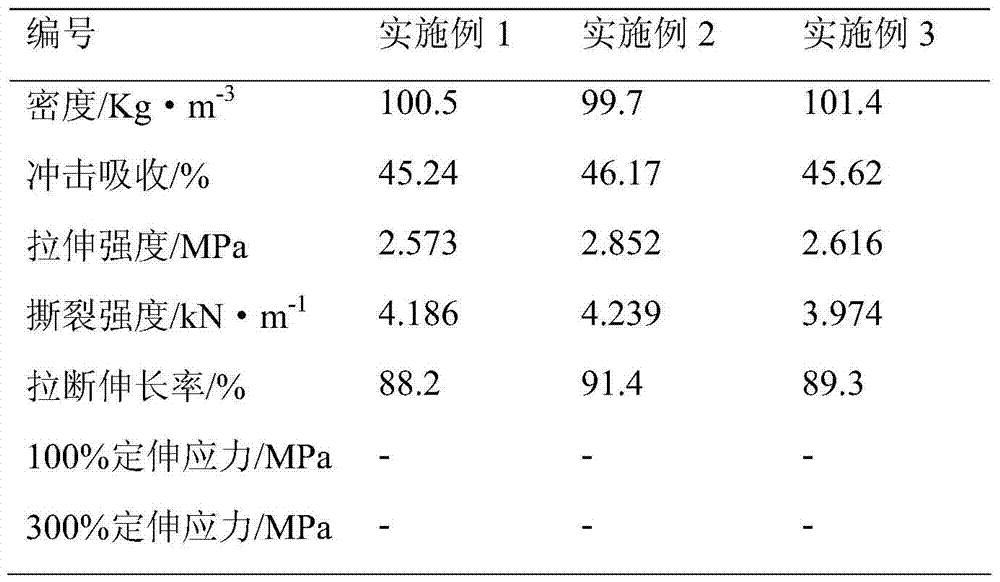

[0035] (1) Preparation of component A, weighed separately: 50 kg of slow-rebound polyether polyol, 30 kg of polyurea polyol Multranol E-9151, 20 kg of high-activity polyether polyol, chain extender ethylene glycol 1.2 kg of alcohol, 1.5 kg of foam stabilizer Silbyk9400, 2.5 kg of water, 0.1 kg of catalyst Dabco BL-11, 5.0 kg of antioxidant Chinox TP-10H, 0.1 kg of light stabilizer Chisorb B2636, 2.0 kg of 800 mesh kaolin Kilogram. Put the weighed slow-rebound polyether polyol, polyurea polyol, and high-activity polyether polyol into the reactor for stirring, and then put in accurately measured chain extenders, catalysts, foam blowing agents, and foam stabilizers. , antioxidants, light stabilizers, solid fillers, physically stirred at room temperature for 4.0 hours, sampling for testing, to meet the testing indicators, that is, the qualified product of component A, discharged from the reactor and loaded into the warehouse .

[0036] (2) For the preparation of component B, add...

Embodiment 2

[0039](1) Preparation of component A, weighed separately: 65 kg of slow rebound polyether polyol, 20 kg of polyurea polyol Multranol E-9154, 30 kg of high activity polyether polyol, chain extender 1,4 - Butanediol 0.6 kg, foam stabilizer SilbykTP 3848 0.1 kg, water 4.5 kg, catalyst Dabco BL-22 1.5 kg, antioxidant Chinox 5411 0.1 kg, light stabilizer Chisorb B2638 5.0 kg, 900 mesh kaolin is 4.0 kg. Put the weighed slow-rebound polyether polyol, polyurea polyol, and high-activity polyether polyol into the reactor for stirring, and then put in accurately measured chain extenders, catalysts, foam blowing agents, and foam stabilizers. , antioxidants, light stabilizers, solid fillers, physically stirred at room temperature for 4.0 hours, sampling for testing, to meet the testing indicators, that is, the qualified product of component A, discharged from the reactor and loaded into the warehouse .

[0040] (2) For the preparation of component B, add 40 kg of polyether polyol EP-240 ...

Embodiment 3

[0043] (1) Preparation of component A, weighing respectively: slow rebound polyether polyol 85 kg, polyurea polyol Multranol E-9128 10 kg, high activity polyether polyol 10 kg, chain extender 1,6 - Hexylene glycol 0.1 kg, foam stabilizer SilbykTP 3849 0.2 kg, water 3.0 kg, catalyst Dabco 8154 2.5 kg, antioxidant Chinox 5571 1.6 kg, light stabilizer Chisorb B2639 2.2 kg, 900 mesh kaolin 5.0 Kilogram. Put the weighed slow-rebound polyether polyol, polyurea polyol, and high-activity polyether polyol into the reactor for stirring, and then put in accurately measured chain extenders, catalysts, foam blowing agents, and foam stabilizers. , antioxidants, light stabilizers, solid fillers, physically stirred at room temperature for 4.0 hours, sampling for testing, to meet the testing indicators, that is, the qualified product of component A, discharged from the reactor and loaded into the warehouse .

[0044] (2) For the preparation of component B, add 60 kg of polyether polyol ED-28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com