Compound technology for extracting tea seed oil employing aqueous enzymatic method

A technology of tea seed oil and composite process, which is applied in the production of fat oil/fat and fat production, can solve the problems of time-consuming and laborious, solvent residue, low yield of clear oil, etc., so as to reduce the production process and production time, and avoid organic solvents. Residual, effect of simplified extraction procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] A composite process for extracting tea seed oil by aqueous enzymatic method, the steps are as follows:

[0091] (1) Remove the tea seeds, crush them, pass through a 60-mesh sieve, and fry them at a constant temperature of 100°C for 20 minutes, and store them in airtight storage for later use;

[0092] (2) Weigh the roasted tea seed powder, add some distilled water and Na 2 CO 3 , NaCl mixed salt solution, fully stirred and mixed, adjust the pH to 9; the reaction solution is Na 2 CO 3 , NaCl, alkaline protease mixed aqueous solution, in which Na 2 CO 3 The concentration ratio of NaCl and NaCl is 0.4mol / L:0.4mol / L, and it is dissolved in some distilled water to make a salt solution before adding;

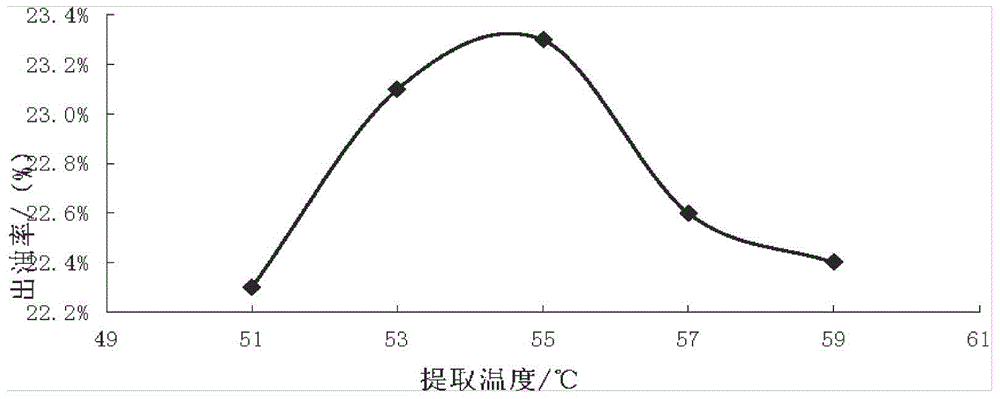

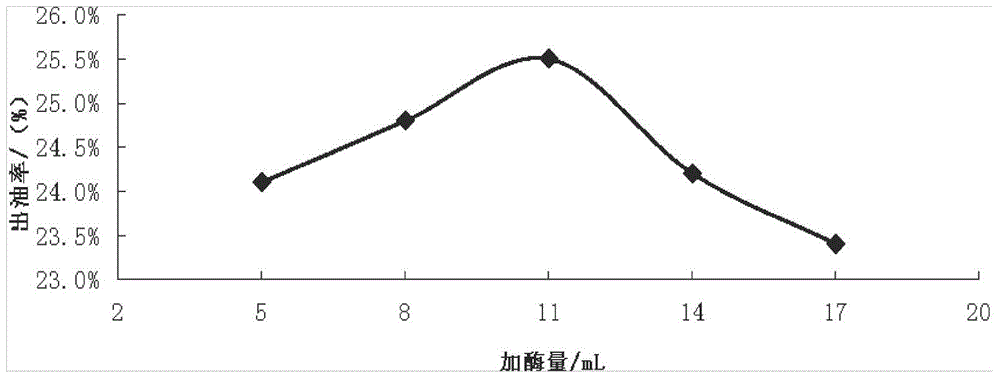

[0093] (3) Warm up the mixed tea seed powder solution to 55°C, then add the prepared enzyme solution under stirring conditions, and close the stirring reaction for 3.5 hours; the enzyme solution is prepared by dissolving alkaline protease in partially distilled water , th...

Embodiment 2

[0096] A composite process for extracting tea seed oil by aqueous enzymatic method, the steps are as follows:

[0097] (1) Shell the tea seeds, crush them, pass through a 60-mesh sieve, and fry at a constant temperature of 100°C for 15 minutes, and set aside;

[0098] (2) Weigh the roasted tea seed powder, add some distilled water and Na 2 CO 3 , NaCl mixed salt solution, fully stirred and mixed; the reaction solution is Na 2 CO 3 , NaCl, alkaline protease mixed aqueous solution, in which Na 2 CO 3 The concentration ratio of NaCl and NaCl is 0.2mol / L:0.8mol / L, and it is dissolved in some distilled water to make a salt solution before adding;

[0099] (3) Warm up the mixed tea seed powder solution to 52°C, then add the prepared enzyme solution under stirring conditions, and stir for 4 hours; the enzyme solution is prepared by dissolving alkaline protease in partially distilled water, alkaline The dosage of protease is 1.68g / KG tea seed powder;

[0100] (4) After the reac...

Embodiment 3

[0102] A composite process for extracting tea seed oil by aqueous enzymatic method, the steps are as follows:

[0103] (1) Remove the tea seeds, crush them, pass through a 60-mesh sieve, and fry them at a constant temperature of 100°C for 30 minutes, and store them in airtight storage for later use;

[0104] (2) Weigh the roasted tea seed powder, add some distilled water and Na 2 CO 3 , NaCl mixed salt solution, fully stirred and mixed, adjust the pH to 8.5; the reaction solution is Na 2 CO 3 , NaCl, alkaline protease mixed aqueous solution, in which Na 2 CO 3 The concentration ratio of NaCl and NaCl is 0.3mol / L:0.6mol / L, and it is dissolved in some distilled water to make a salt solution before adding;

[0105] (3) Warm up the mixed tea seed powder solution to 57°C, then add the prepared enzyme solution under stirring conditions, and close the stirring reaction for 3 hours; the enzyme solution is prepared by dissolving alkaline protease in partially distilled water, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com