Preparation method for titanium alloy with high dynamic bearing performance and low cost

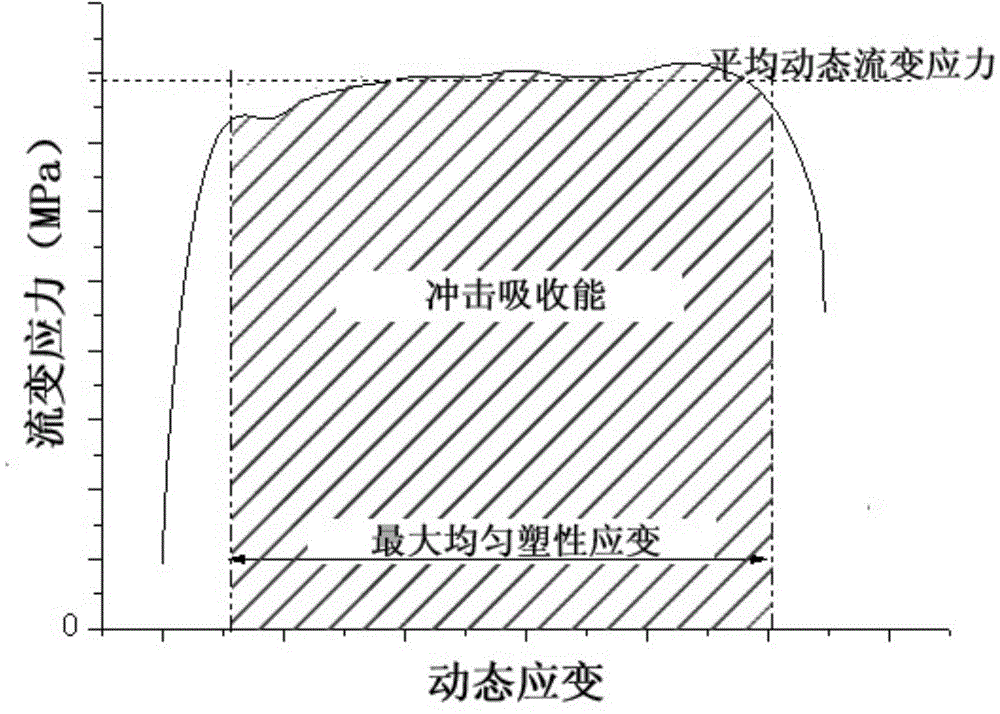

A titanium alloy and high dynamic technology, which is applied in the preparation of low-cost titanium alloy, the preparation of low-cost titanium alloy plate or bar with high dynamic performance, and the field of high dynamic load-bearing performance. Toughness measurement and other issues to achieve the effect of reducing the cost of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the high dynamic load-carrying performance and low-cost titanium alloy bar or plate of the present invention comprises the following steps:

[0026] (1) Alloy target composition range

[0027] The composition of the alloying elements (percentage by weight) is as follows: aluminum 2.5% to 7.0%, vanadium 2.0% to 5.5%, iron less than or equal to 2.5%, oxygen 0.1% to 0.3%, other impurity elements less than 0.1% alone and the total less than 0.4%, The rest is titanium.

[0028] (2) Ingredients

[0029] According to the target ingredients described in step (1), the ingredients are mainly composed of: titanium alloy residue, titanium sponge, aluminum-vanadium master alloy, vanadium-iron master alloy, or three master alloys of aluminum-vanadium-iron A combination of one or more, as well as elemental aluminum or iron. The composition grade of titanium alloy residue is industrial pure titanium or titanium alloy containing at least one of the three ele...

Embodiment 1

[0035] According to the method provided by the present invention, a titanium alloy rod with high impact absorption energy-high dynamic plasticity and low cost is prepared, and the specific steps are as follows:

[0036] Step (1) Determine the alloy target composition

[0037] The nominal composition is: Ti-2.5Al-5V-2.5Fe-0.2O. Other impurity elements are less than 0.1% alone and less than 0.4% in total.

[0038] Step (2) Ingredients

[0039] According to the target composition of step (1), according to the ingot weight of 100kg, the ingredients are 20kg of Ti-10V-2Fe-3Al or TB6 alloy residue, 72.8kg of titanium sponge, 1.8kg of aluminum-50 vanadium master alloy, iron -50 vanadium master alloy 4.2kg, aluminum beans 1.0kg, titanium dioxide 0.2kg. The residual material is crushed into a lath shape with a width and thickness not greater than 20mm.

[0040] Step (3) Melting and deformation processing

[0041] Mix the raw materials described in step (2) evenly in the mixing dev...

Embodiment 2

[0045] According to the method provided by the present invention, a low-cost titanium alloy plate with good impact absorption energy-strength-plasticity matching is prepared, and the specific steps are as follows:

[0046] Step (1) Determine the alloy target composition

[0047] The nominal composition of the designed titanium alloy is: Ti-5.5Al-2.0V-2.0Fe-0.1O. Other impurity elements are less than 0.1% alone and less than 0.4% in total.

[0048] Step (2) Ingredients

[0049] According to the target composition of step (1), according to the ingot weight of 1000kg, the ingredients are 300kg of Ti-6Al-4V or TC4 alloy residue, 637kg of titanium sponge, 12kg of aluminum-50 vanadium master alloy, and 12kg of iron-50 vanadium master alloy. Alloy 4kg, aluminum beans 21kg, titanium dioxide 1.0kg. The residual material is crushed and processed into particles with a diameter not greater than 40mm.

[0050] Step (3) Melting and deformation processing

[0051] Mix the raw materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com