Sapphire reinforcing method

A sapphire and annealing furnace technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of microscopic damage on the surface of sapphire lens, affecting the bending strength of sapphire, and the surface appearance cannot meet the requirements, and achieves the realization of Mass production, low production cost, and the effect of reducing surface burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Take a certain model of mobile phone sapphire panel as an example.

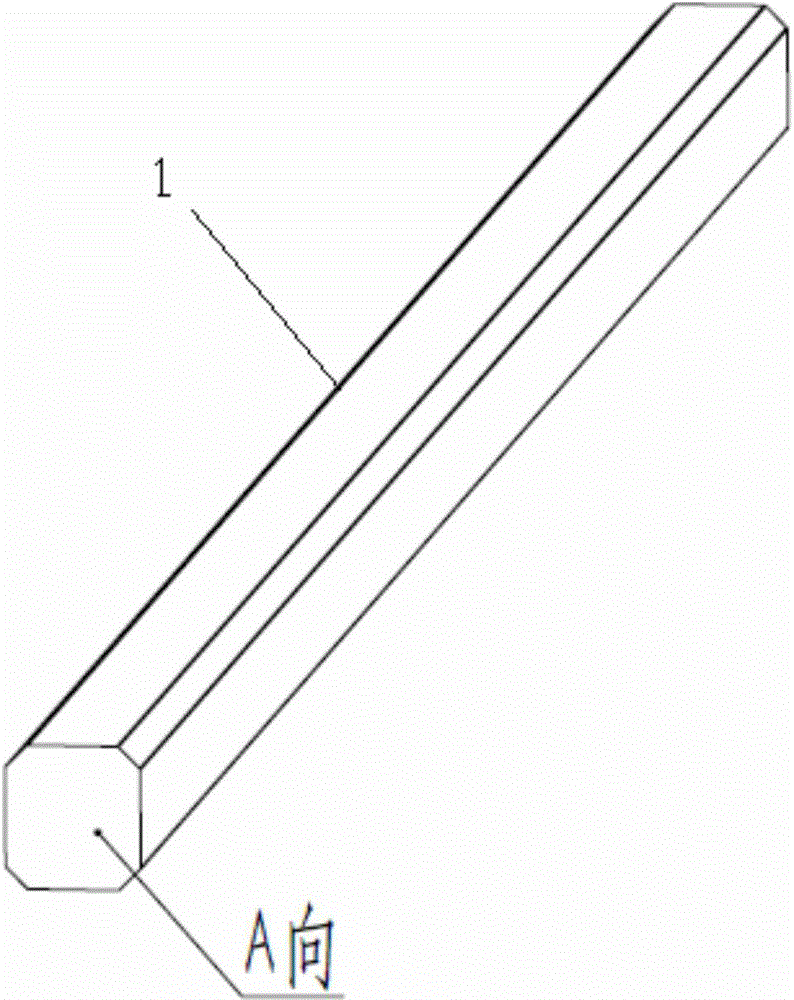

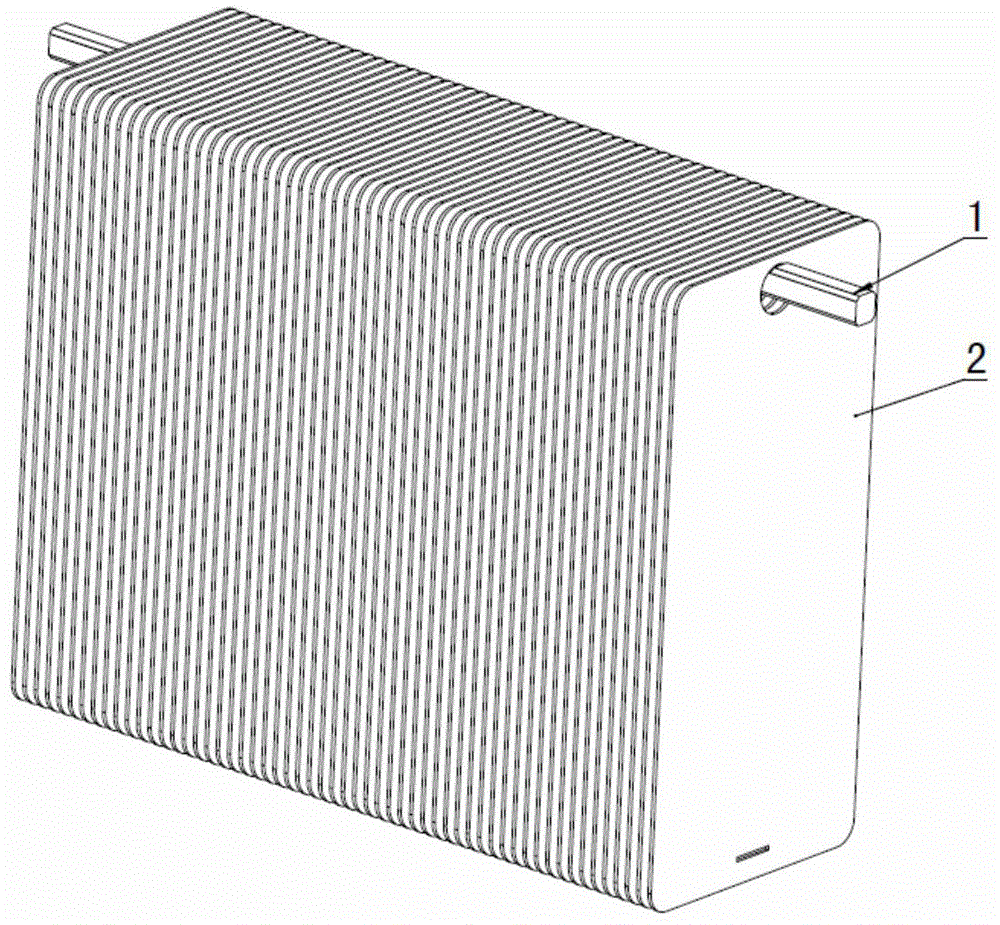

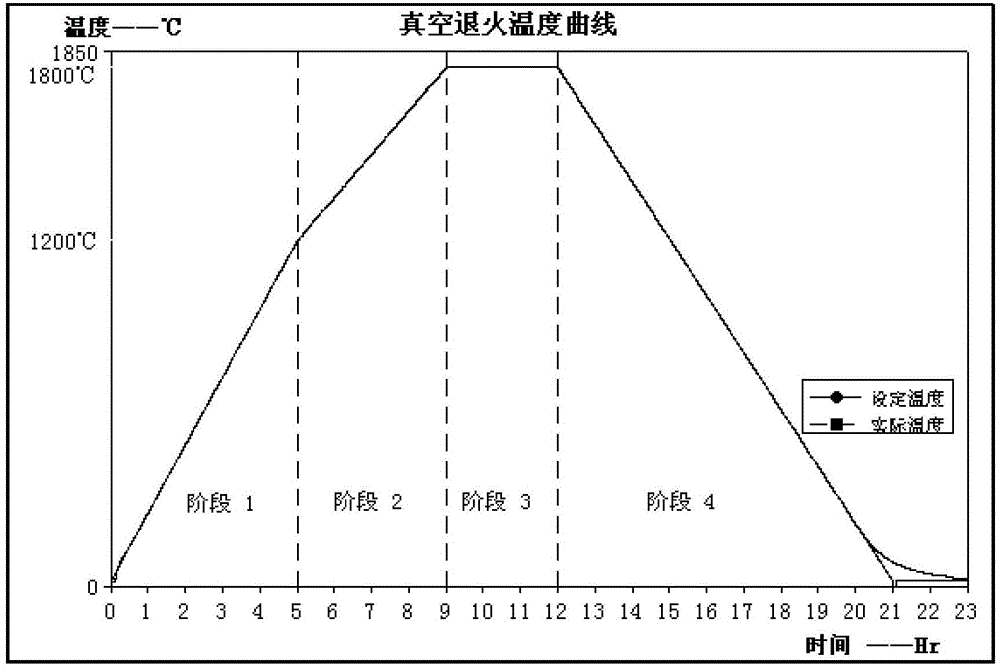

[0026] First, prepare the jig for making the sapphire lens. Processing as figure 1 As shown in the sapphire ingot 1, firstly, the sapphire ingot 1 is processed into a long strip with a square cross-section, and the four edges are chamfered. When the sapphire ingot is processed, the end face crystal orientation is A direction, and the A direction is the sapphire most The non-slip surface can be used continuously in the annealing furnace at a high temperature of 1800℃ without creeping and bending; the surface of the ingot can be polished with a 250# grinding wheel. Before use, the sapphire crystal rod 1 is fired in an annealing furnace under an air atmosphere at a temperature of 1500°C for 3 hours, and can be used after cooling down.

[0027] Then, follow the steps below to anneal and strengthen the sapphire.

[0028] Step 1: Place the cleaned sapphire product for 10 minutes under a deionizing fan to remove s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com