High-warmth-keeping breathable knitted double-faced pile and processing method thereof

A processing method and technology of double-faced fleece, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of poor thermal insulation effect and air permeability, affecting consumers' wearing comfort, easy shedding, pilling, etc. Achieve the effect of excellent suede style, good anti-pilling performance and thick hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Process and produce high thermal insulation and breathable knitted double-face fleece fabric of the present invention as follows:

[0022] 1. Fabric name

[0023] 150D / 144F polyester triangular shaped HOY+75D / 36F DTY double-sided fleece (flat fleece)

[0024] 2. Yarn product name

[0025] 150D / 144F polyester triangular shape HOY; 75D / 36F DTY

[0026] 3. Weaving process

[0027] Lida UBX-2TR model single-sided towel machine is selected, the machine number is 24G, the cylinder diameter is 26", the pile height is 2.5mm, the base yarn is 75D / 36F DTY conventional polyester yarn, and the loop yarn is special 150D / 144F polyester triangular special-shaped HOY, weaves a single-sided terry fabric with a compact and smooth structure on the front and a terry structure on the back.

[0028] 4. Dyeing and finishing process

[0029] Dyeing - sizing machine drying - sizing machine plus fluffing agent - napping - sizing - combing - shearing - finished product sizing

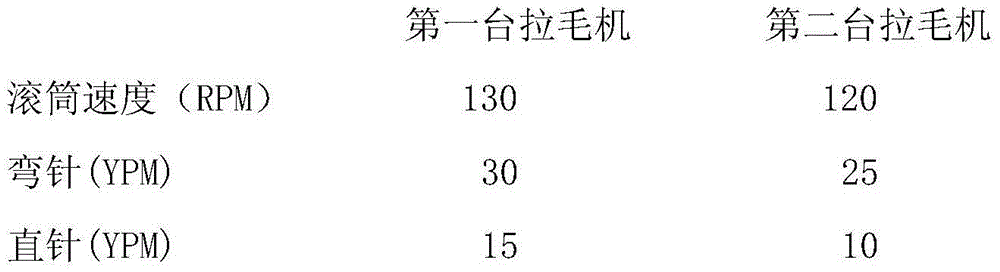

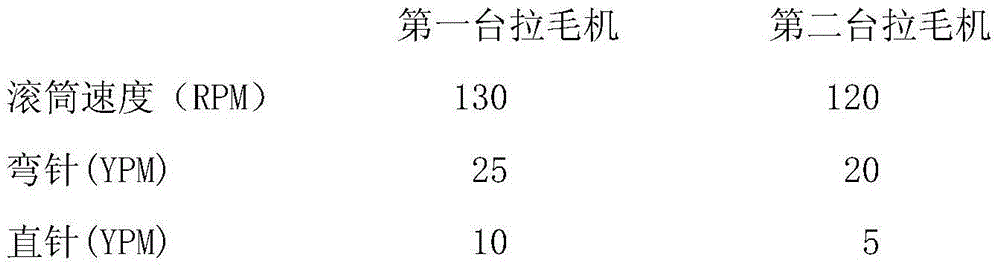

[0030] (Usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com