Movable assembly type house

A kind of prefabricated and housing technology, applied in the direction of architecture, building structure, etc., to achieve the effect of protecting natural forest resources, good ventilation performance, and flexible design and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

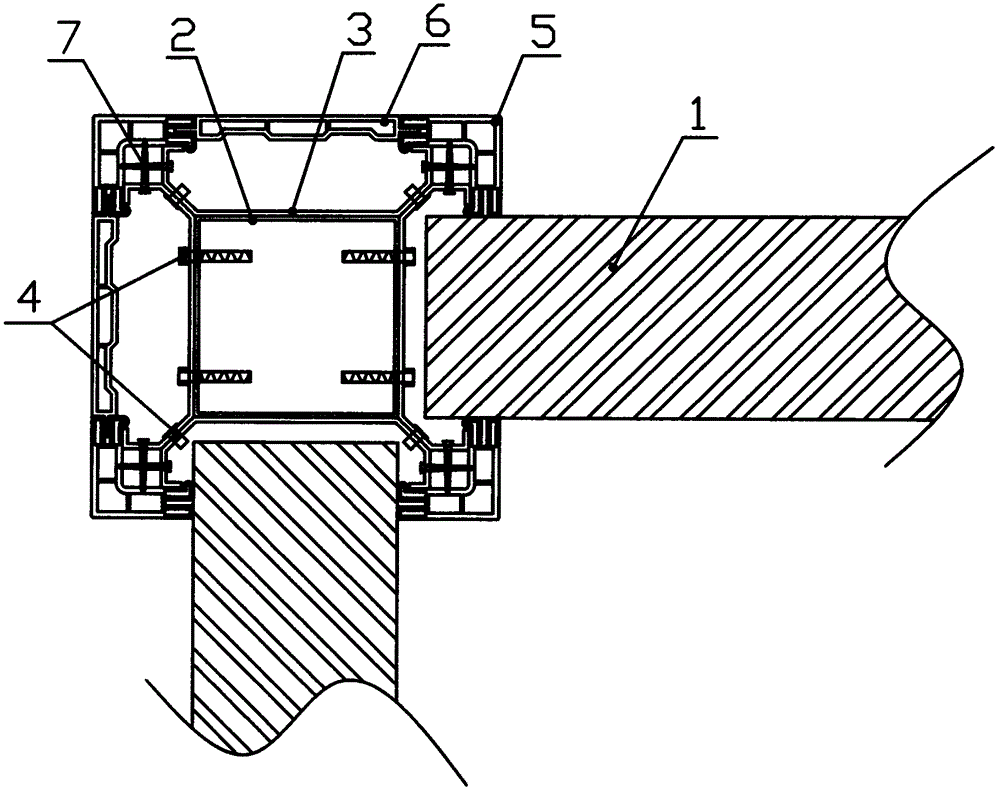

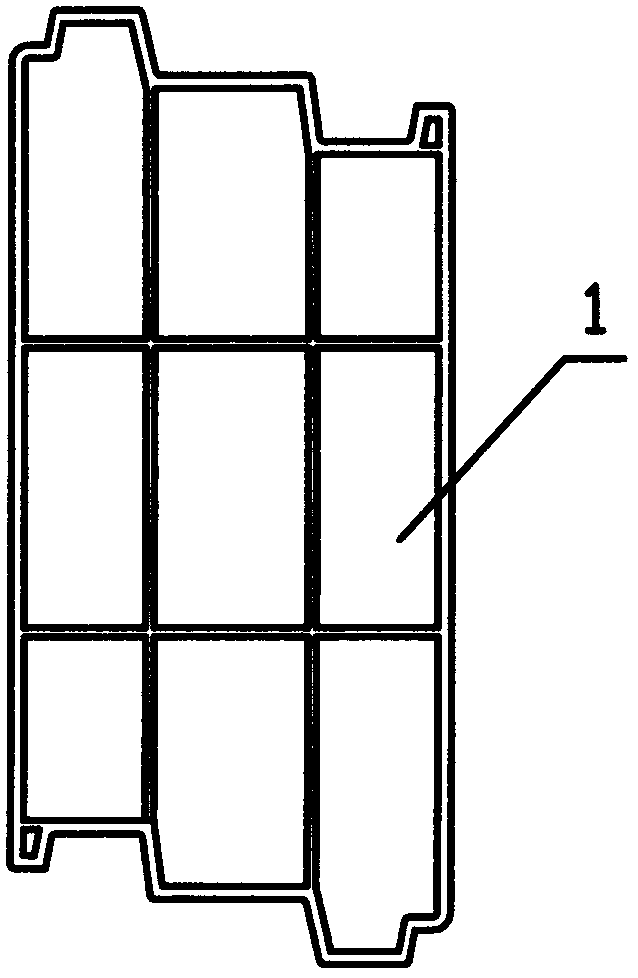

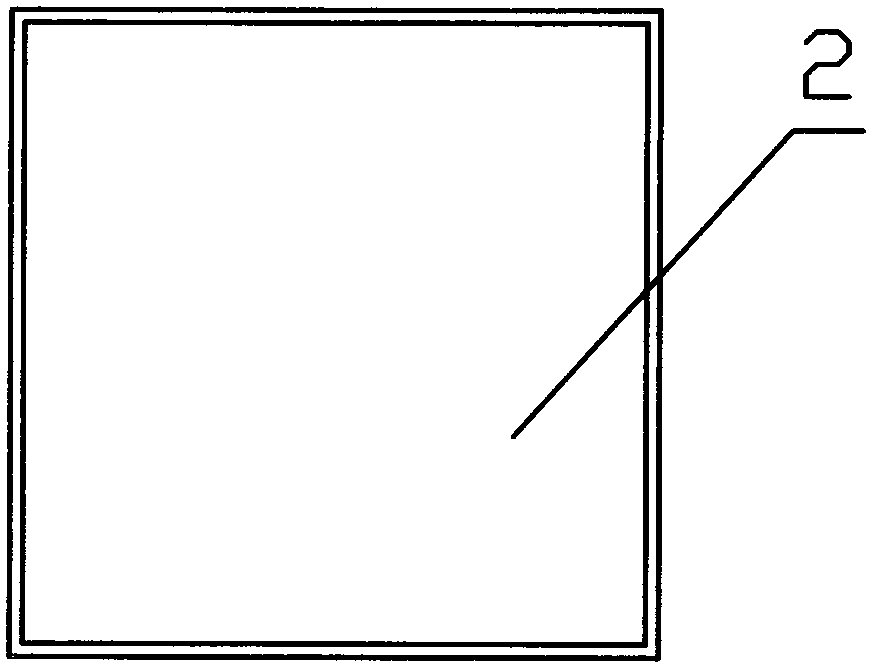

[0020] In order to overcome the defects of the existing prefabricated house structure, considering that the composite wood and the wall can achieve a unified material effect, and can also reflect the distinction between the columns and beams of the wooden house, the visual effect is the same as that of the wooden structure house, reflecting the perfect combination of steel and wood integrated wood houses ; Combining the unique chemical stability and excellent mechanical and physical properties of the co-extruded cladding composite material-Kangnan composite wood, and the combination of composite wood and steel, can achieve 100% recycling, green environmental protection, energy saving and emission reduction. Design a steel-wood composite house structure with steel as the main body, and composite wood on the outside of the steel, including load-bearing galvanized steel columns 2 and wall panels 1 around the house, and the bottom of the wall panel 1 according to needs The wall pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com