Vertical shock insulation support and manufacturing method thereof

A technology of vertical vibration isolation and manufacturing method, which is applied in the direction of earthquake protection, bridge parts, building components, etc., can solve the problems of poor vertical vibration isolation effect, difficult to overcome torsional shear moment, complex structure and manufacturing process, etc. It achieves the effect of good vertical isolation effect, simple structure, and is conducive to wide popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

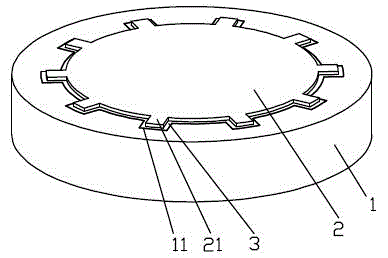

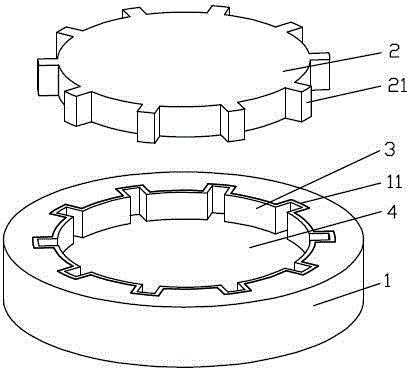

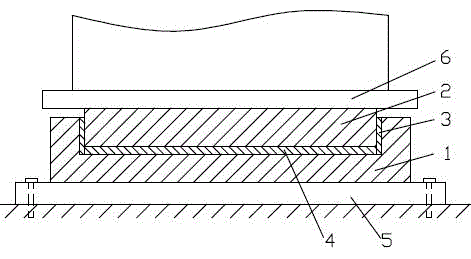

[0022] Figure 1 to Figure 3 It shows the vertical shock-absorbing support provided by the present invention, including the lower support seat 1 with a groove and the upper support plate 2 located in the groove; ribs 21 are arranged on the periphery of the upper support plate 2, and the groove Rib grooves 11 matching the convex ribs 21 are provided on the groove walls; damping layers 3 are arranged on the groove walls of the rib grooves 11 and grooves, and shock-absorbing layers 4 are arranged on the bottom of the grooves.

[0023] The upper support plate 2 is a cylindrical plate with at least two convex ribs 21, which are arranged symmetrically in the center of the periphery of the upper support plate 2, so that it can better bear the shear force uniformly as a whole, so that each rib groove 11 The damping layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com