Deep hole blasting and static water injecting combining coal seam weakening method

A technology for deep hole blasting and coal seam weakening, which is applied in blasting, earth drilling, ground mining, etc., and can solve problems such as easy collapse of boreholes, easy blockage of static pressure water injection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

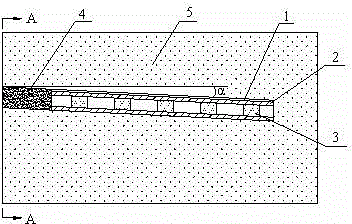

[0019] The present invention provides a coal seam weakening method combining deep hole blasting and static pressure water injection. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail in conjunction with the accompanying drawings and examples below .

[0020] A coal seam weakening method combining deep hole blasting and static pressure water injection, characterized in that the method comprises the following steps:

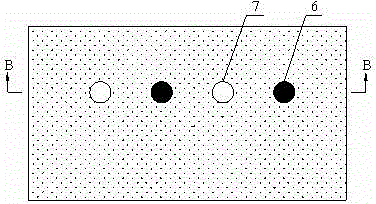

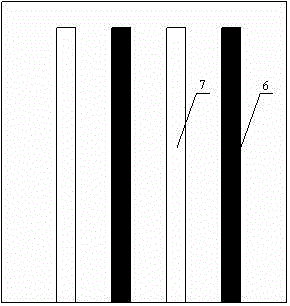

[0021] (1) Arranging several sets of boreholes 1 in the coal seam, each set of boreholes 1 includes a blast hole 6 and a control hole 7;

[0022] (2) Push the hole-protecting tubes 2 with a diameter less than 10mm into the control hole 7 one by one, and wrap the adjacent hole-protecting tubes 2 longitudinally with steel wires;

[0023] (3) Put the explosive roll 3 into the hole-protecting tube 2 according to the charge density of the line, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com