Spiral oil suction pipe for refrigerator compressor

A technology for refrigerator compressors and oil suction pipes, which is applied to mechanical equipment, machines/engines, liquid variable capacity machines, etc. It can solve the problems of affecting the service life of frequency conversion compressors, damage of frequency conversion compressors, and large oil pump resistance, etc., to achieve Long service life, small oil absorption resistance and large pump oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

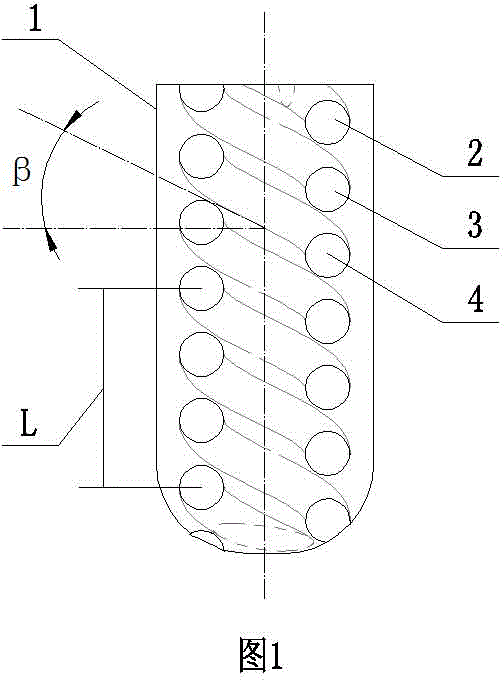

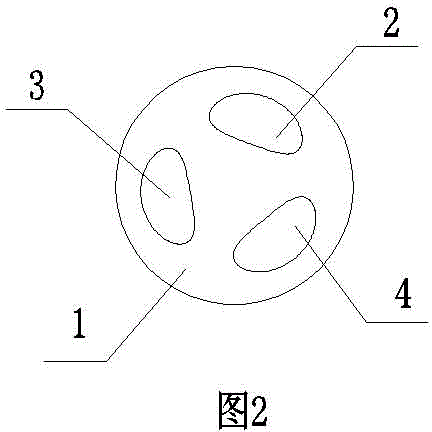

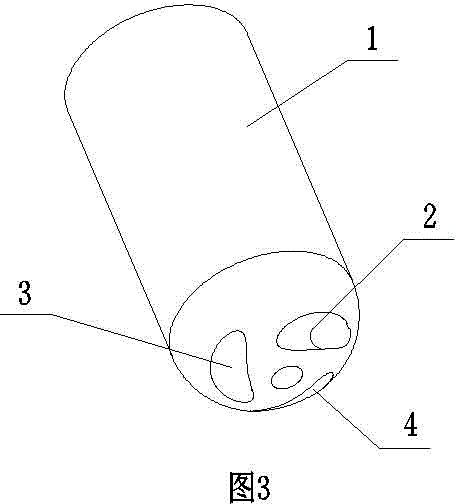

[0016] The spiral oil suction pipe used for refrigerator compressors is composed of an oil suction pipe body 1 and an embedded spiral pipe. The oil suction pipe body 1 is in the shape of a cylinder, and more than one columnar embedded spiral pipe is formed in the oil suction pipe body 1. The embedded spiral pipe is coaxial with the oil suction pipe main body 1, and the oil suction pipe main body 1 is connected with the end surface of the crankshaft 5 after being fixed through the central hole of the motor rotor 6.

[0017] The embedded spiral pipeline can be composed of an embedded spiral pipeline a2; it can also be composed of two spiral pipelines, the embedded spiral pipeline a2 and the embedded spiral pipeline b3; it can also be formed by the embedded spiral pipeline a2 1, embedded spiral pipeline b3 and embedded spiral pipeline c4 are composed of three spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com