Multistage pressure-limiting adjusting hydraulic buffer

A hydraulic buffer and adjustable technology, which is applied in the field of hydraulic buffers, can solve the problems of insufficient energy consumption, high acceleration, and unavoidable car crashes and fatalities, and achieve stable and uniform damping force, fast response, extended buffer stroke and collision the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

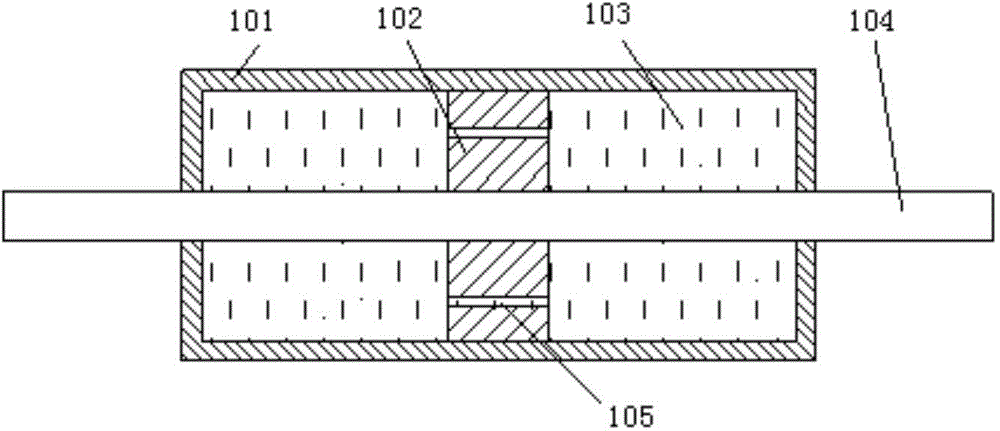

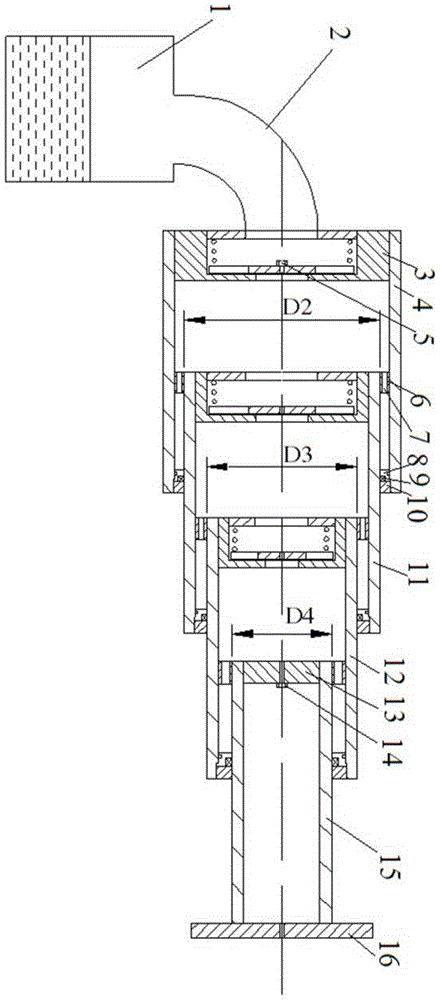

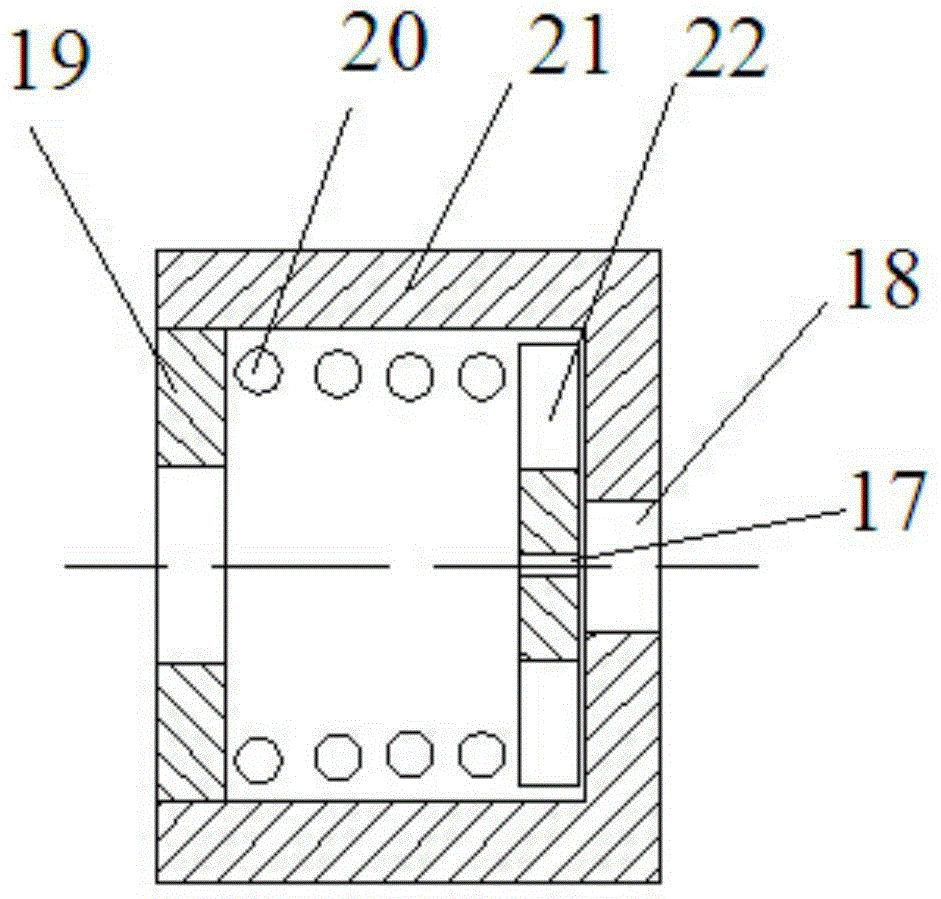

[0022] Such as figure 2 As shown, the present invention includes four-stage buffer mechanisms connected sequentially from left to right, and each stage buffer mechanism of the first three-stage buffer mechanisms includes a cylinder body, a pressure-limiting adjustable overflow valve 3, a sealing seat 8, a sealing ring 9 and The end cover 10, wherein the second buffer mechanism and the third buffer mechanism also include a guide ring 6; the fourth buffer mechanism includes a fourth cylinder 15, a screw plug, a screw, a pressure bearing plate 16 and a guide ring 6.

[0023] From left to right, the cross-sectional diameters of the buffer mechanism cylinders decrease successively, the left end of the fourth cylinder 15 is threadedly connected with the screw plug 14, and the outer wall of the left end of the fourth cylinder 15 is provided with a guide ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com