Method for machining ceramic valve ball with hole in center and ceramic valve ball machining device

A processing method and processing device technology, applied in valve devices, metal processing equipment, cocks including cutting devices, etc., can solve the problem of difficult product size and precision control, spherical surface roughness difficult to meet technical standards, zirconia sphere processing Difficulty and other problems, to achieve stable and reliable processing quality, stable and reliable spherical processing quality, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

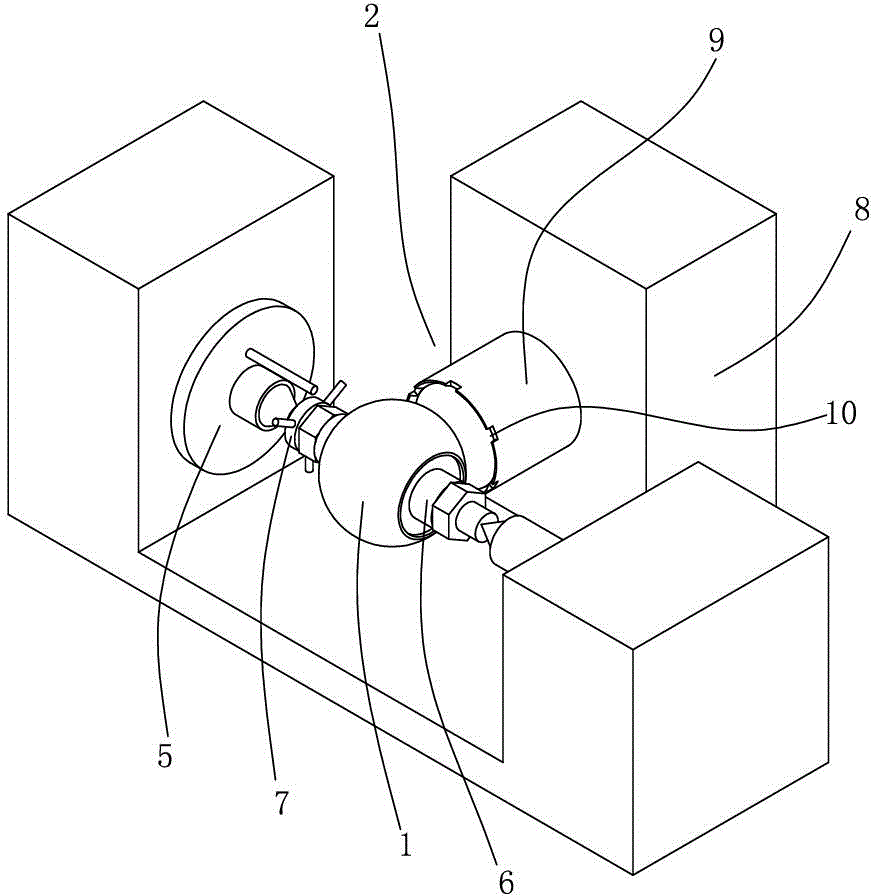

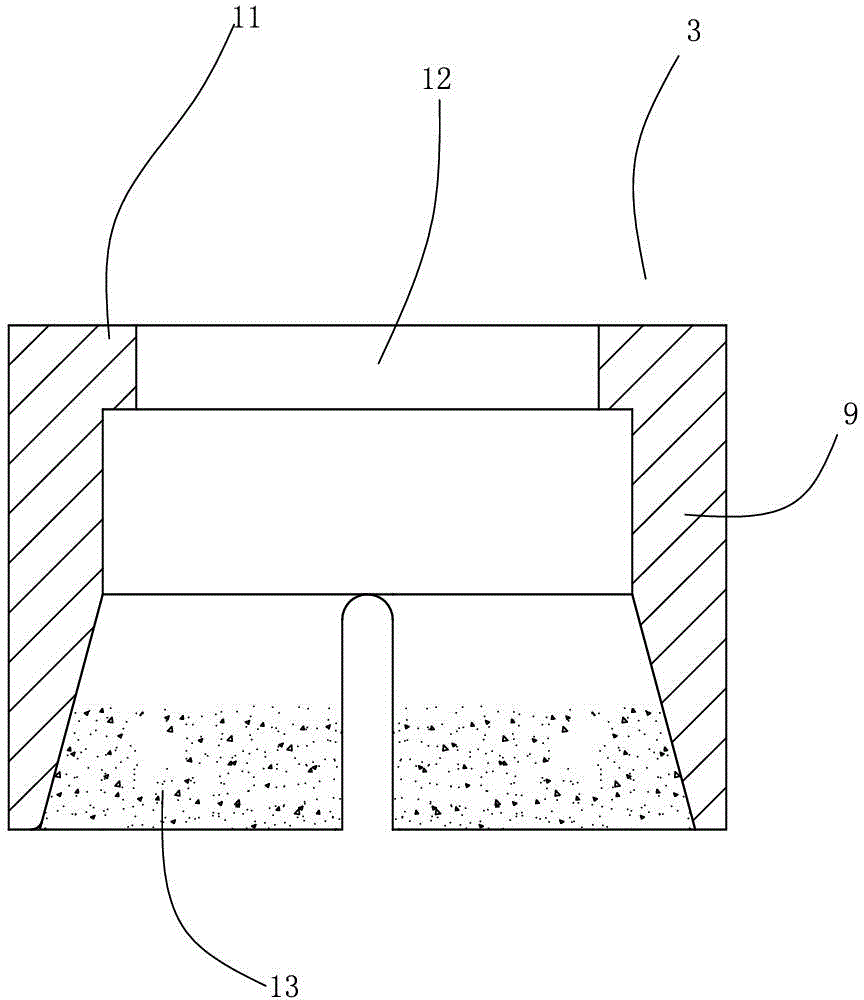

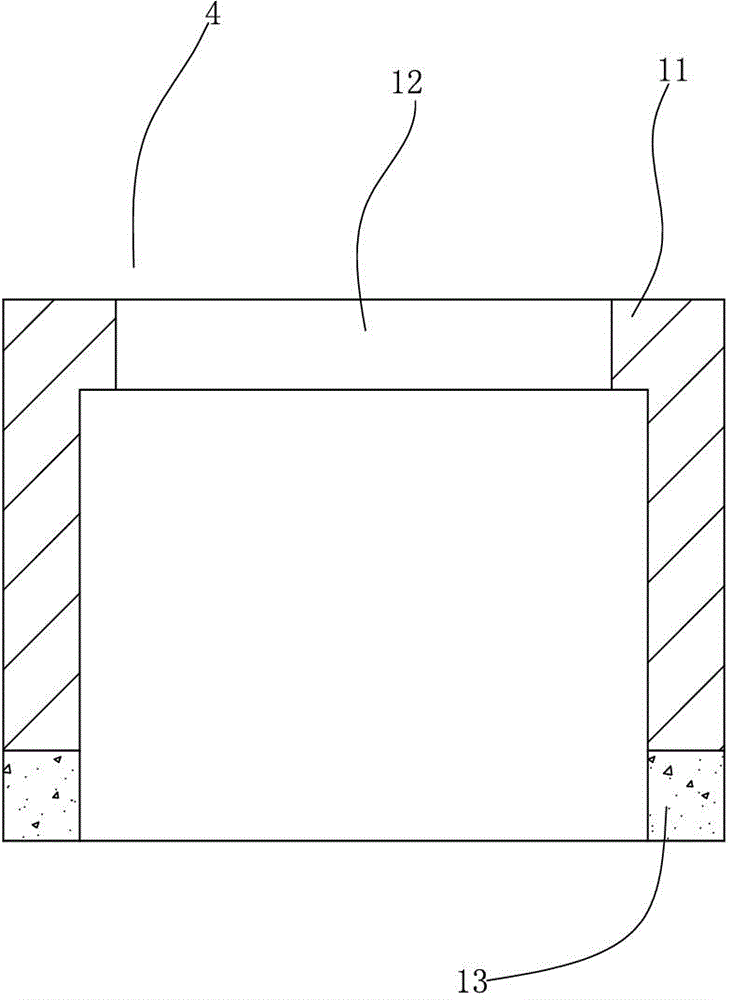

[0032] Example: such as Figure 1 to Figure 5 Shown, a kind of processing method of the ceramic valve ball with hole in the center of the present invention, it comprises the following steps:

[0033] (1) Powder pressing and green body processing: the powder is pressed into a valve ball green body with a hole in the center, and the pressed valve ball green body is fixed on a lathe, grinder or special machine tool. Rough turning, finishing turning, cutting to length on the outer surface, and then grinding the rough peak;

[0034] (2) Sintering: Put the green body of the valve ball in the furnace, raise the temperature from room temperature to the preset maximum temperature in several stages, and keep warm for each stage, and then drop from the highest temperature to the preset temperature in several stages. Out of the furnace temperature, out of the furnace to form ceramic sintered balls;

[0035] (3) Grinding the center hole: fix the ceramic sintered ball 1 on a lathe, grinde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap