Three-dimensional measurement method of fringe reflection based on binary fringe defocus

A three-dimensional measurement and fringe reflection technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of reducing measurement accuracy and blurring of deformed fringe images, filtering out high-order harmonics, improving projection speed, and overcoming gamma. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

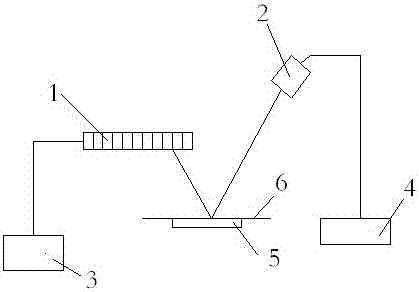

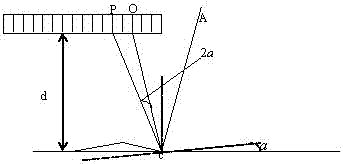

[0028] The present invention works and implements like this, the three-dimensional measurement method of fringe reflection based on binary fringe defocus is characterized in that it consists of three key parts: binary fringe coding principle, defocus projection system, and fringe reflection measurement principle.

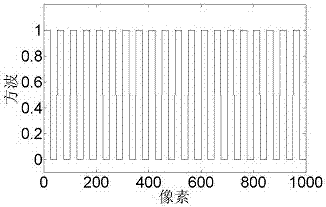

[0029] 1. The principle of binary stripe coding

[0030] The computer-coded binary stripes only have two gray values (0 and 255). When the input light intensity is 0 or 255, the output light intensity will not change. The light intensity distribution of the coded binary stripes is (such as image 3 shown):

[0031]

[0032] 2. Binary fringe out-of-focus projection

[0033] By performing a Fourier analysis on the binary fringes:

[0034]

[0035] The Fourier spectrum G(f) of g(x) x )yes:

[0036] G(f x ) = Csinc(f x / 2f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com