Piezoelectric type decoupling micro-vibration measurement system

A measurement system and micro-vibration technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, and electrical devices, etc., can solve problems such as complex processing, and achieve the effects of simple data processing, flexible interface size, and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

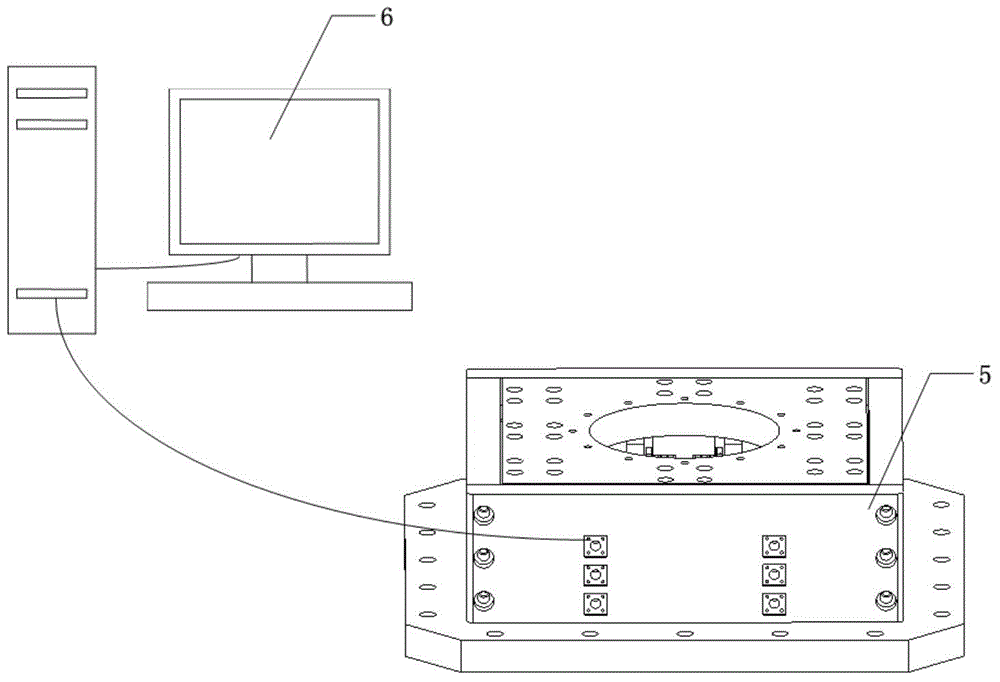

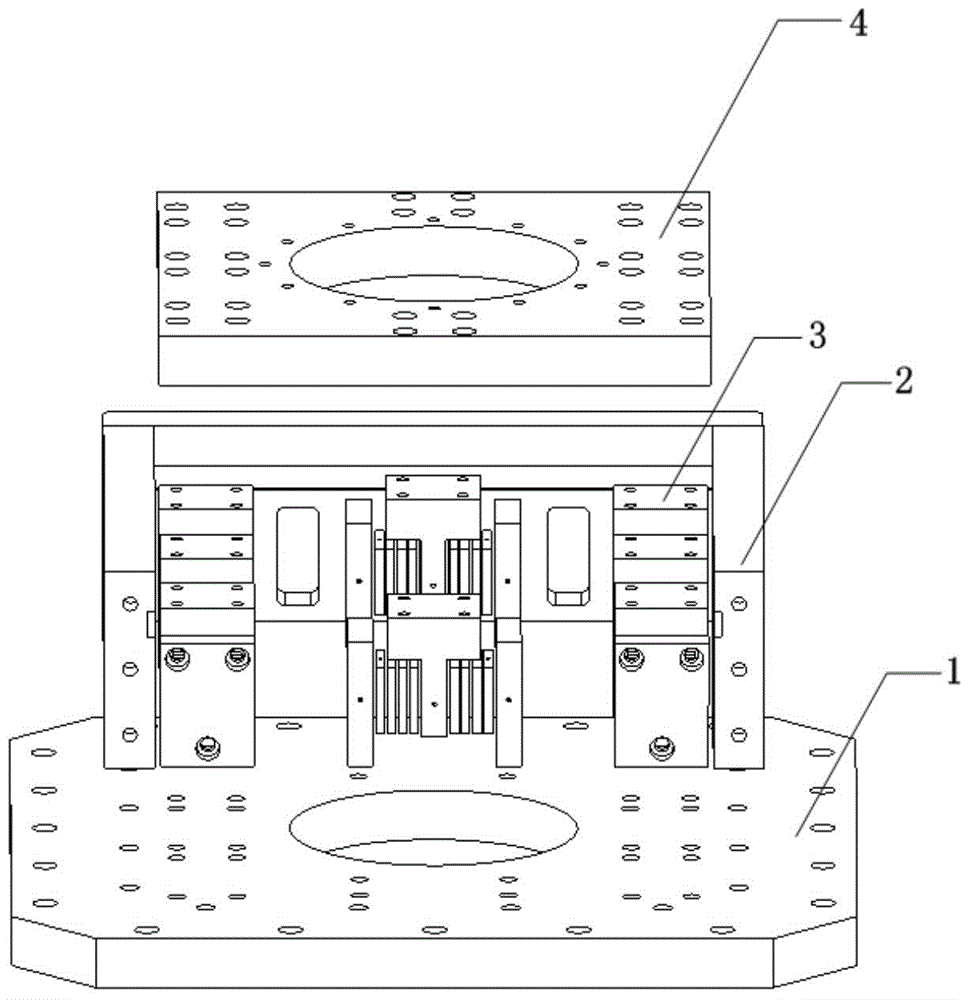

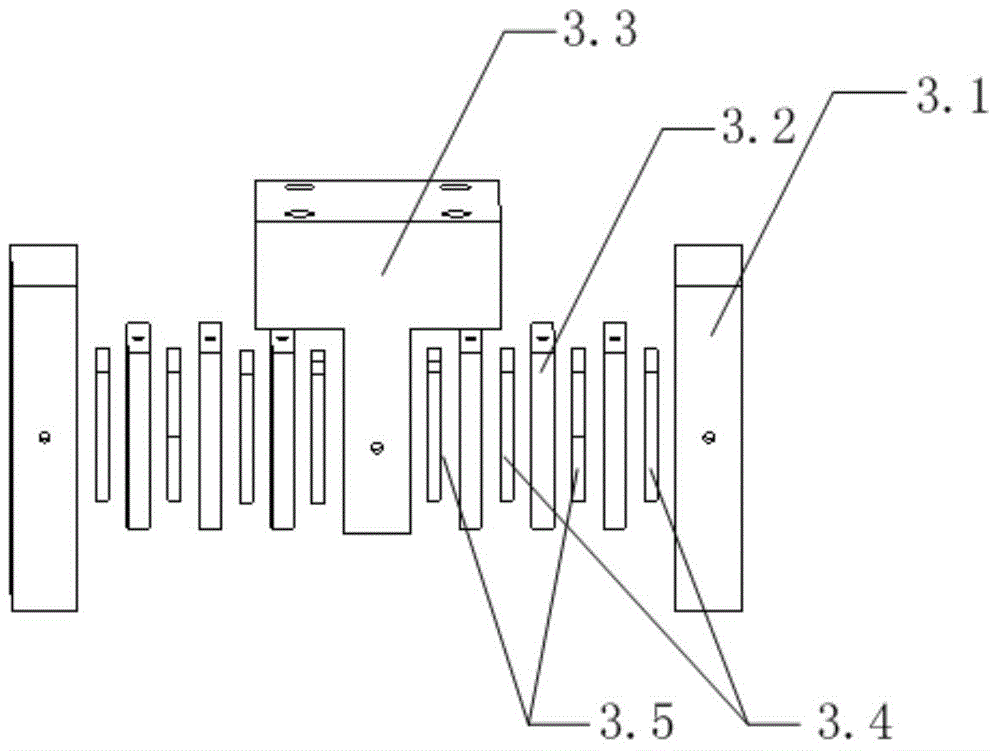

[0023] like figure 1 , figure 2 ,and image 3As shown, the three side plates 2 and the terminal plate 5 are surrounded by M10 bolts and fixed on the bottom plate 1 by M10 bolts; the eight shear-type piezoelectric sensors 3 have the same structure, and the six sensors 3 are equal to each other. The spacing is close to the inside of the two side plates 2 in the X-axis direction, and the other two sensors 3 are placed close to the inside of the side plate 2 and the wiring board 5 in the Y-axis direction; the eight sensors 3 and the bottom plate 1 are tightened by M8 bolts; the load The plate 4 is placed above the sensor 3 and tightened by M8 bolts; each sensor 3 is composed of five parts, namely the side column 3.1, the spacer 3.2, the middle column 3.3, the insulating sheet 3.4 and the piezoelectric sheet 3.5; the installation and use of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com