Device for simplifying internal combustion wave rotor experiment based on relative movement

A technology of internal combustion wave rotor and experimental device, which is applied in the direction of internal combustion engine testing, etc., can solve the problems of difficulty in observing the flame structure in the channel of the data acquisition wave rotor, the unclear interaction mechanism between flame and complex wave system, and increase the complexity of the system, etc., to achieve convenience Qualitative research, avoiding difficulties in data collection, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

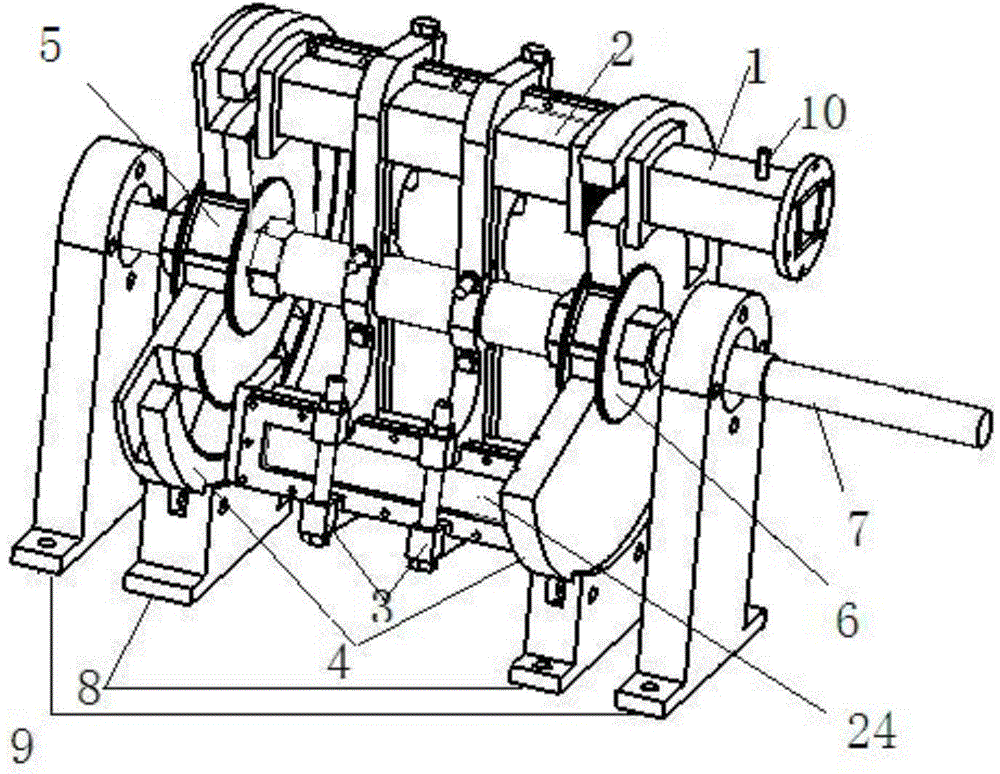

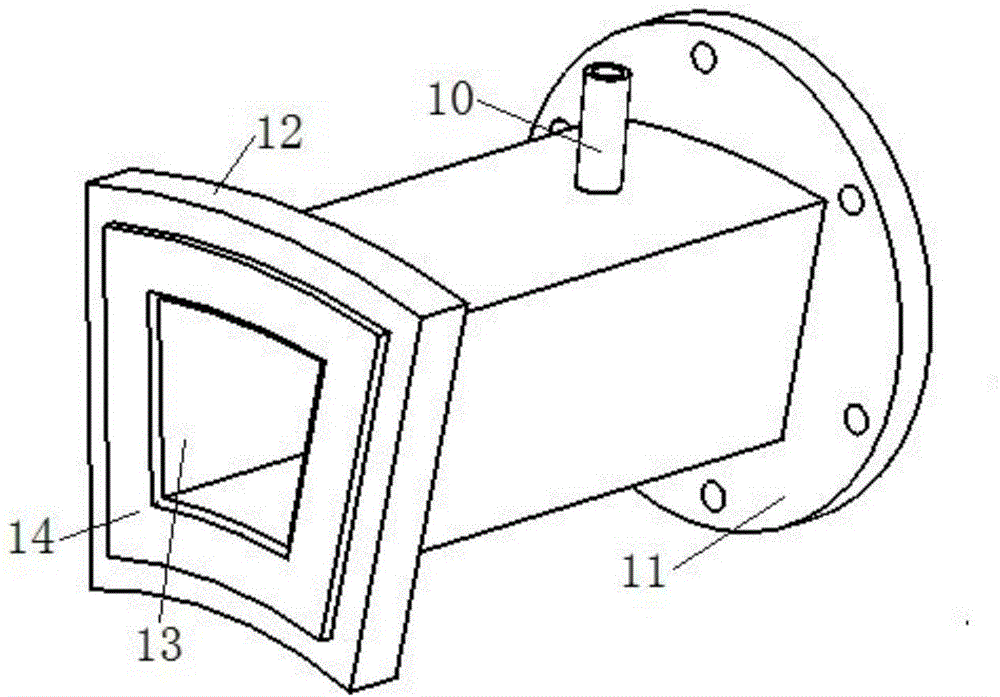

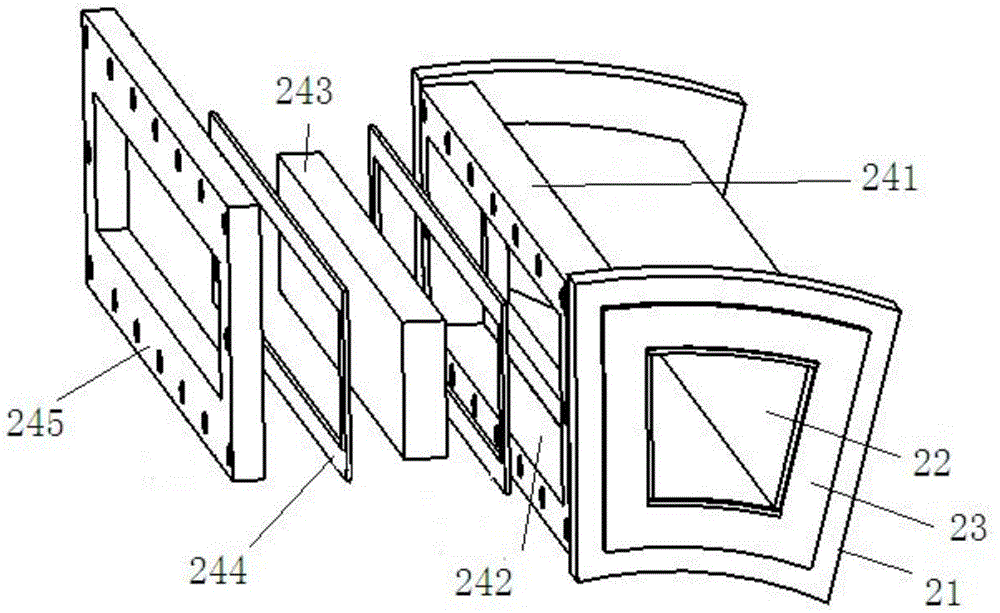

[0044] Considering the effect of the centrifugal force field, the sealing disc 4 is fixed on the base 8, the wave rotor channel 2 rotates relative to the sealing disc 4, and the installation sequence of the observation window 24 on the wave rotor channel 2 is copper gasket 244---quartz glass 243---copper gasket 244---observation window cover plate 245, the wave rotor channel 2 is fixed between the long arm 33 connecting one support unit and the broken arm 36 of another support unit, the long arm 33 and the short arm 36 The tension bolts 38 between them are tightened, and the centrifugal force generated by the rotation mainly acts on the tension bolts 38, so as to prevent the long arm 33 of the connecting bracket 3 from being greatly deformed due to the centrifugal force of the wave rotor channel 2, which will affect the stability of the system. The long arm 33 of the support 3 is in contact with the vertical arm 34 and a rounded corner is excessively 37, which eliminates the st...

no. 2 example

[0046] When studying the interaction mechanism between the shock wave and the flame, the effect of the centrifugal force field can be ignored. At this time, the wave rotor channel 2 is fixed (it is easy to achieve fixation, not shown in the drawings), and the sealing plate 41 at the inlet end passes through the connector 5 and the rotating shaft 7 In order to prevent the relative movement between the sealing disk 41 at the inlet end, the connector 5 and the rotating shaft 7 during the rotation process, the positioning disk 6 is arranged on both sides of the sealing disk 41 at the assembled inlet end and the connector 5, and the positioning nut is used to 61 fix the three, the first outlet end sealing disc 421 and the second outlet end sealing disc 422 are overlapped to ensure that the third annular hole 425 and the fourth annular hole on the two sealing discs overlap, and the second annular hole 423 and the gap 424 overlap, fix the connector 5, the sealing disc 4 and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com