Tension tester for super tonnage winch

A tensile testing machine and ultra-large tonnage technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve problems such as safety, pulley efficiency loss, hidden dangers, etc., to achieve accuracy assurance, high test efficiency, and test Get data reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is further described:

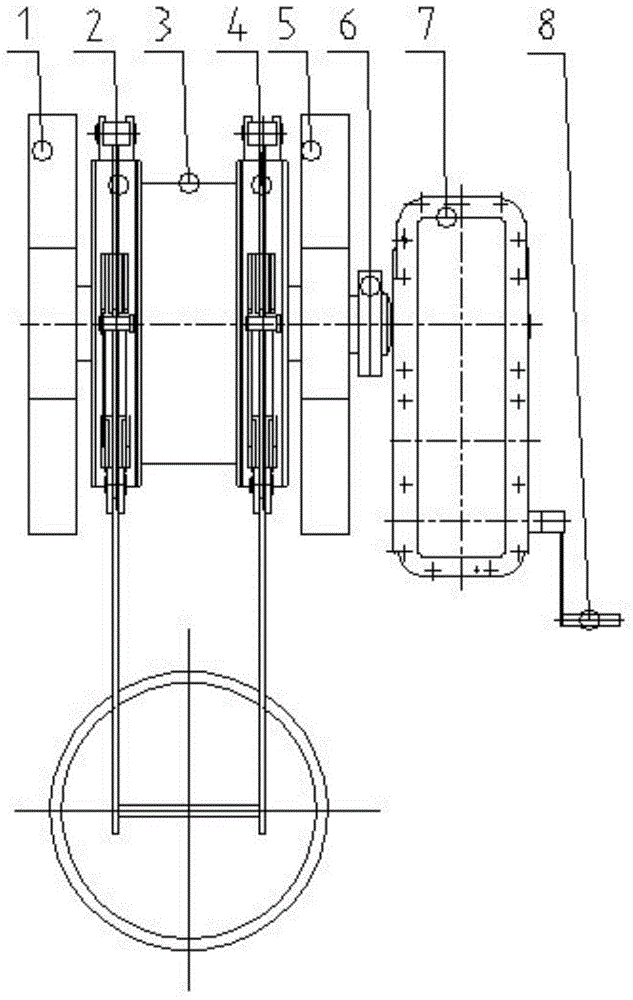

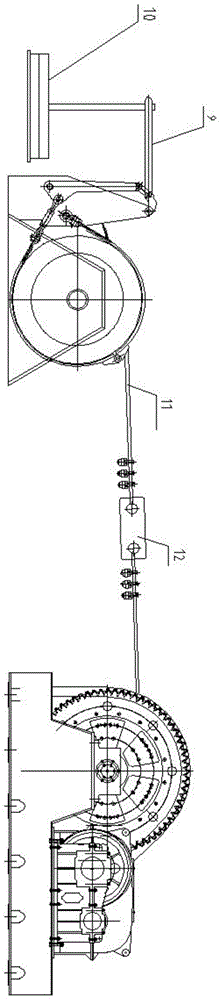

[0014] refer to Figure 1~2 As shown, a tensile testing machine for a super-large-tonnage winch includes a support I1 and a support II5 fixedly arranged on the foundation, a reel 3 erected between the support I and the support II, and a reel wound on the reel A test steel rope 11, the free end of the test steel rope is connected with one of the test ends of the plate ring type tension sensor 12, and the other test end of the plate ring type tension sensor is connected with the steel rope of the winch to be tested; The rear end of the support I and the support II is provided with a lever 9, and one end of the lever is connected with the reel brake band 2, 4, and the other end of the lever is hoisted for pulling the brake band brake reel, and placed There is a weight disc with weights 10; the extended end of the rotating shaft of the reel is connected to the power output shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com