Tungsten series or molybdenum series polyoxometallate supermolecular compound as well as preparation method and application thereof

A technology of polyoxometalates and supramolecular compounds, which is applied in the field of photocatalysis to achieve high catalytic efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

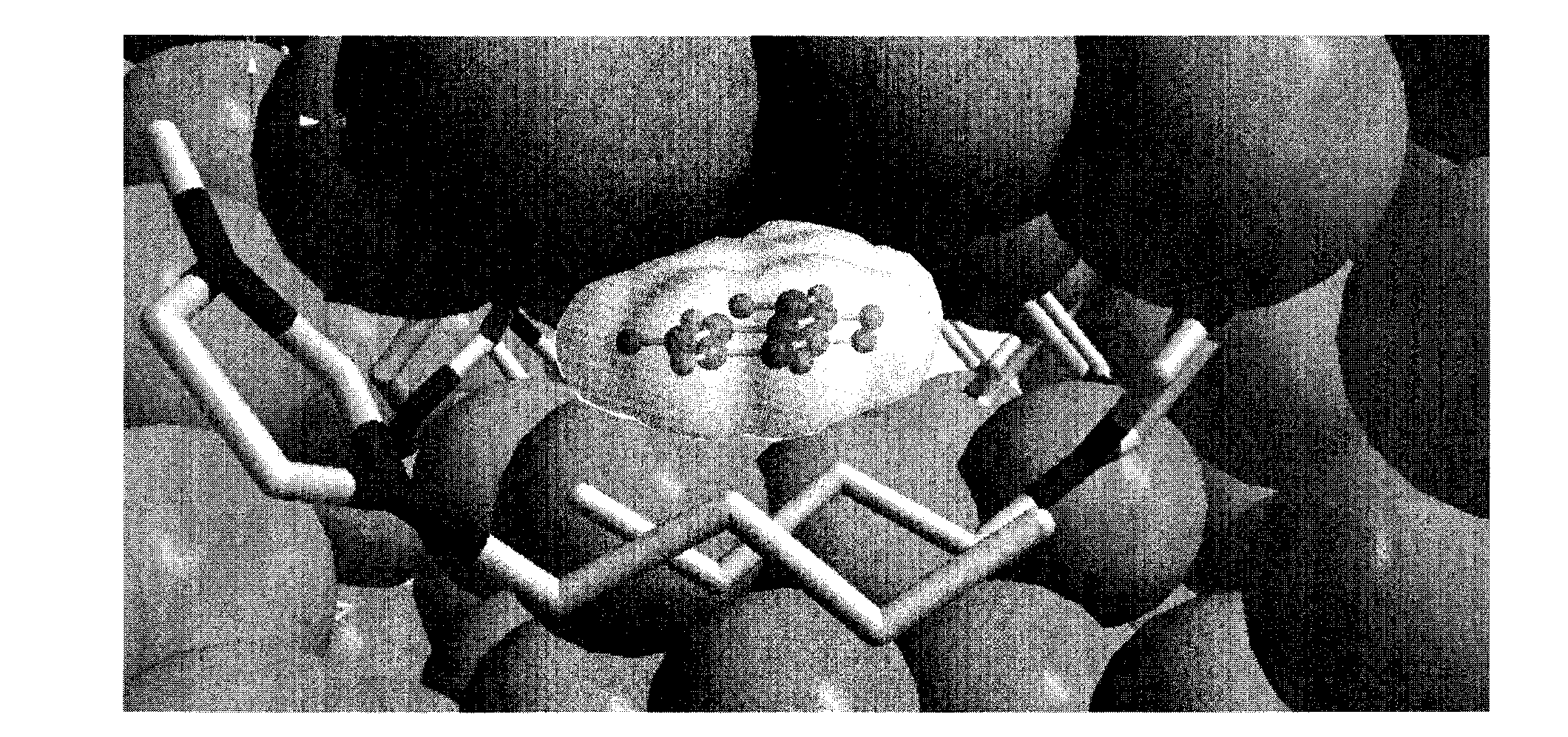

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 photocatalyst

[0037] In a 250mL four-necked bottle, add 100mL of absolute ethanol and 100g of phosphotungstic acid respectively, and stir to dissolve them completely. 100 mL of 1-methyl-3-butylimidazole chloride with a mass concentration of 20% was added dropwise, and white flocs gradually appeared in the system. Stirring was maintained for 2 hours and then left to stand overnight. The product was centrifuged and dried in vacuo to recall the desired Catalyst 1. During the reaction, the reaction temperature was maintained at -20°C. Through X-ray diffraction, obtain the X-ray single crystal diffraction of photocatalyst namely crystal structure data as follows:

[0038] Bond precision: C-C=0.0177A Wavelength=0.71073

[0039] Cell: a=17.895(5) b=18.391(5) c=16.676(4)

[0040] alpha=90beta=90 gamma=90

[0041] Temperature: 291K

[0042] Calculated Reported

[0043] Volume 5488(3) 5488(3)

[0044] Spac...

Embodiment 2

[0062] The preparation of embodiment 2 photocatalysts

[0063] In a 250mL four-necked bottle, add 100mL of absolute ethanol and 100g of aluminophosphate respectively, and stir to dissolve them completely. 50 mL of 1-methyl-3-butylimidazole bromide with a mass concentration of 25% was added dropwise, and white flocs gradually appeared in the system. Stirring was maintained for 2 hours and then left to stand overnight. The product was centrifuged and dried in vacuo to recall the desired Catalyst 2. During the reaction process, the reaction temperature was always maintained at 0°C.

Embodiment 3

[0064] The preparation of embodiment 3 photocatalysts

[0065] In a 250mL four-necked bottle, add 100mL of absolute ethanol and 100g of phosphotungstic acid respectively, and stir to dissolve them completely. 20 mL of 1-methyl-3-butylimidazole iodide with a mass concentration of 30% was added dropwise, and white flocs gradually appeared in the system. Stirring was maintained for 2 hours and then left to stand overnight. The product was centrifuged and dried in vacuo to recall the desired Catalyst 3. During the reaction, the reaction temperature was maintained at 10°C.

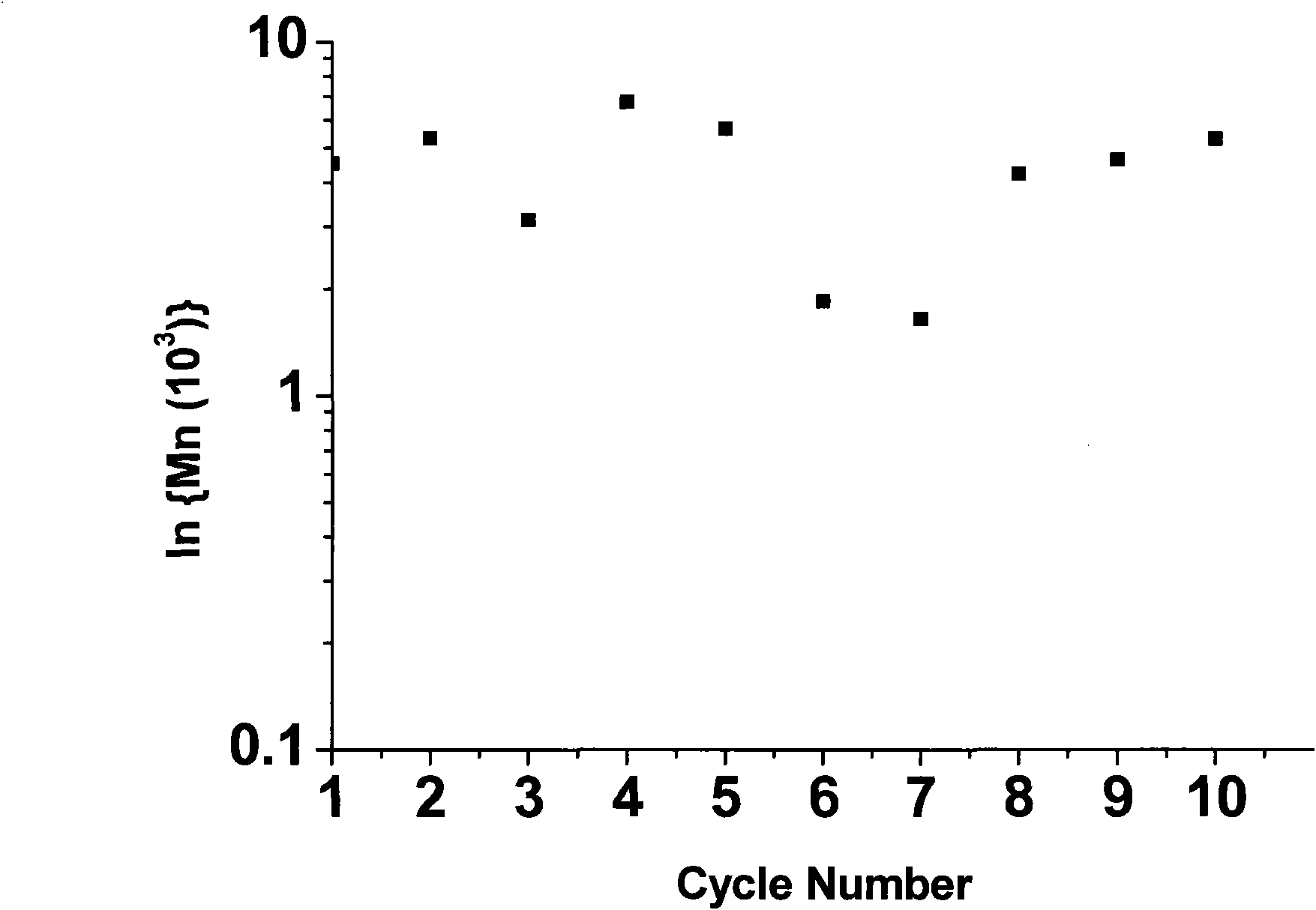

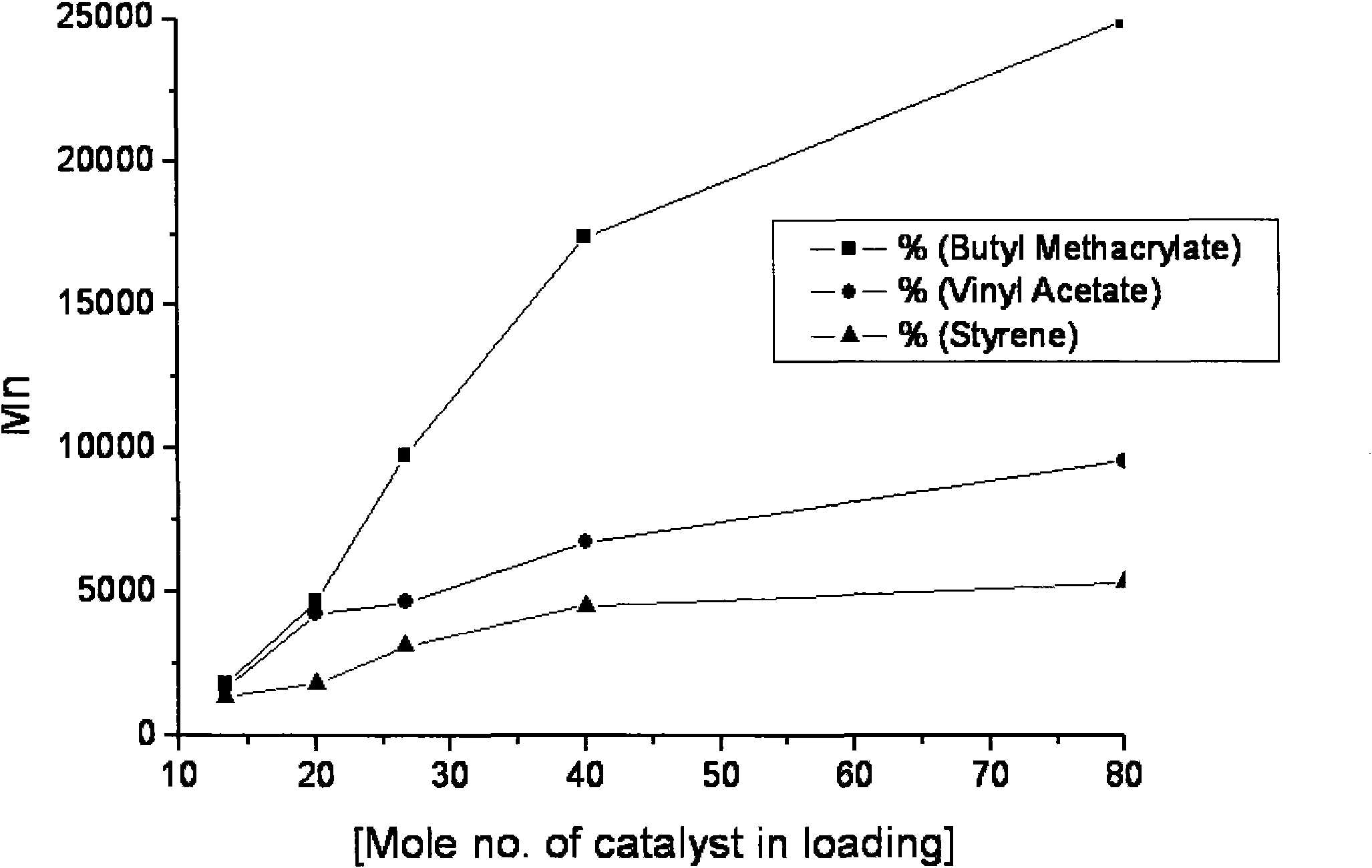

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com