Constant-voltage closed-loop-controlledautomatic tail gas collecting method and constant-voltage closed-loop-controlled automatictail gas collecting device

A closed-loop control and automatic collection technology, which is applied in the direction of measuring devices, sampling devices, volume measuring instruments/methods, etc., can solve the problems of backwardness and cannot meet the rapid development of gas energy, and achieve the effect of improving the accuracy of volume measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

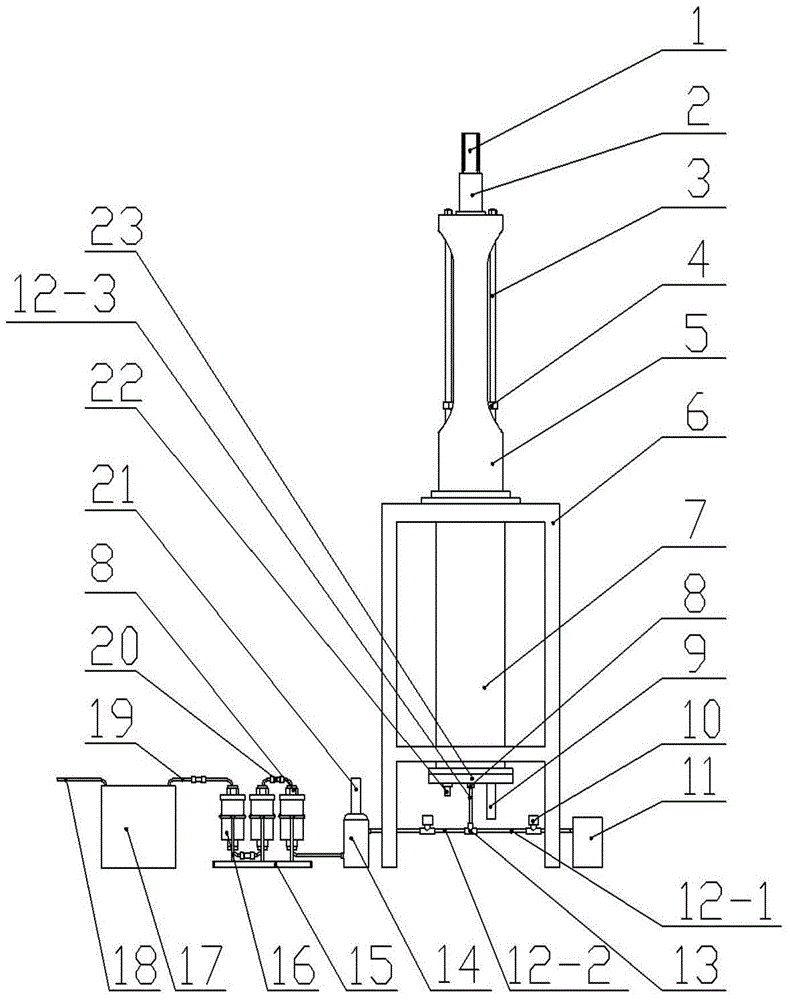

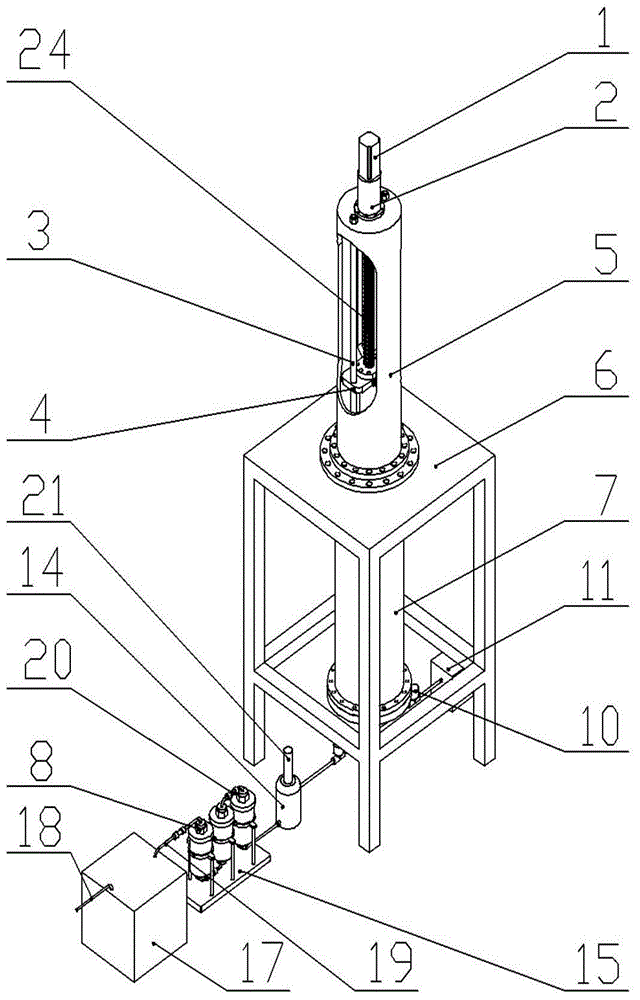

[0015] Such as figure 1 and figure 2 As shown, the upper end of the piston cylinder 7 in the present invention is fixed on the plane of the support 6 by screws, and the plane upper end of the support 6 is fixed to the sleeve 5 by screws; one end of the piston rod installed in the piston cylinder 7 is connected with the piston, and the other end is welded On the connection plate 4; the two ends of the connection plate 4 are equipped with guide rods 3, the magnetic scale reading head is fixed on one side of the connection plate 4 through the support, and the corresponding magnetic strip is attached to the inner wall of the sleeve 5; the ball screw The lower end of 24 is connected with the piston rod, and the other end passes through the sleeve 5 and is connected with the servo motor 1 through a coupling, and the ball nut of the ball screw is fixed on the connecting plate 4; the servo motor 1 is fixed on the shaft cover 2 On the sleeve 5, the lower end of the piston cylinder 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com