Auto-collection method and device for tail gas self-adjusting motor speed according to flow value

A technology of automatic collection and motor speed, applied in sampling devices and other directions, can solve the problems of backwardness and cannot meet the rapid development of gas energy, and achieve the effect of improving the accuracy of volume measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

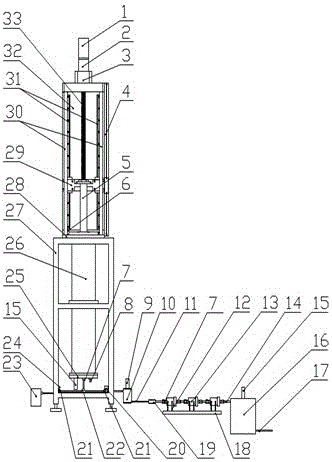

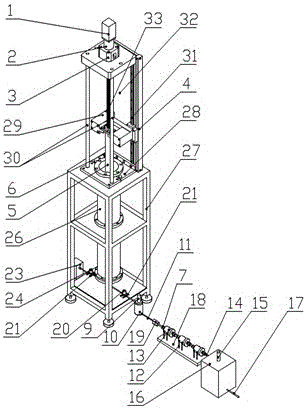

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] like figure 1 and figure 2 As shown, the servo motor 1 in the present invention is fixed on the upper end steel plate of the base 32 through the speed reducer 2 through the fixed sleeve 3, and the speed reducer 2 is connected with one end of the ball screw 33 through a shaft coupling. The end of the screw rod 33 is supported by a bearing, and the bearing is fixed on the upper steel plate of the base 32; the other end of the ball screw 33 is connected to the inside of the piston rod 5 through a ferrule, and the ball nut matched with the ball screw 33 Fixed with the piston rod 5 on the flange. The flange of the piston rod 5 is fixed to the moving block 29 by screws, and the moving block 29 is fixed to the linear guide rail 31 installed on the base 32 . The scale grating of the grating ruler 4 is fixed on the base 32 side, and the reading head of the grating ruler 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com