Gas emission determinator and method for determining trace nitrogen emission flux using same

A gas emission and measurement device technology, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as low measurement results, inability to distribute acetylene evenly, and inability to completely inhibit microbial reduction, and achieve the effect of eliminating nitrogen leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

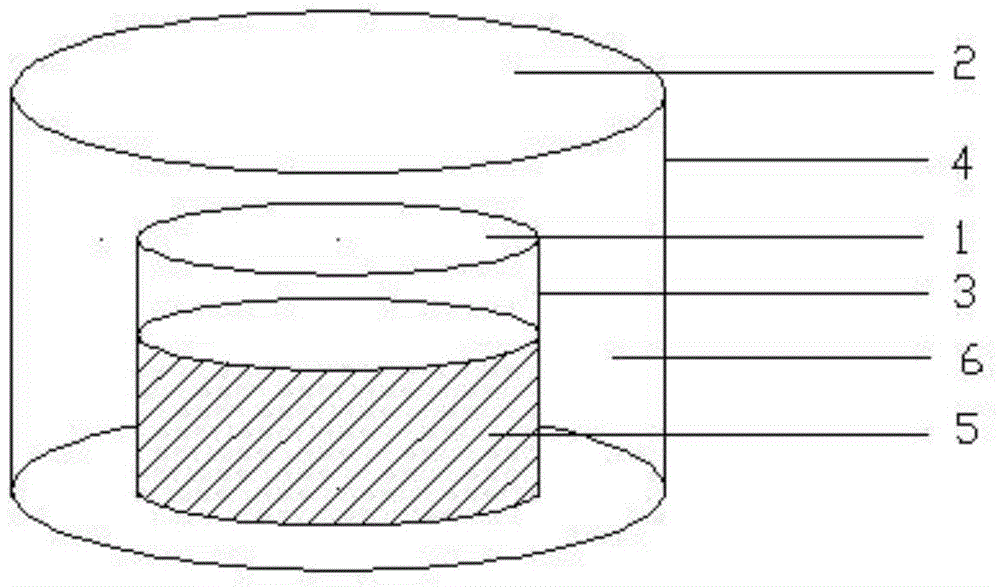

[0029] Specific embodiment 1, when the culture starts, the nitrogen concentration C in the inner sealed tank 3 2 50μg L -1 , Nitrogen concentration C in inner sealed tank 3 after cultivation 1 52.14μg L -1 , The gas volume V of the inner sealed tank 3 is 1.14L, and the soil column area A is 0.038m 2 , When the incubation time T is 10h, the method of using the gas emission measuring device to measure the trace nitrogen emission flux includes the following steps:

[0030] A. Prepare the undisturbed soil and place the soil to be measured into undisturbed soil pillars 5 and place them in the inner sealed tank 3. The height of the undisturbed soil pillars is 130mm. According to the height of the soil pillars, determine the nitrogen emission flux F N In the calculation formula, the gas volume V of the inner sealed tank 3 is 1.14L, and the inner rubber sealing cover 1 made of butyl rubber is used to seal the inner sealed tank 3, because the butyl rubber has low air permeability and good ai...

specific Embodiment 2

[0036] Specific embodiment 2, when the cultivation starts, the nitrogen concentration C in the inner sealed tank 3 2 100μg L -1 , Nitrogen concentration C in inner sealed tank 3 after cultivation 1 150.3μg L -1 , The gas volume V of the inner sealed tank 3 is 1.90L, and the soil column area A is 0.038m 2 , When the incubation time T is 5h, the method of using the gas emission measuring device to measure the trace nitrogen emission flux includes the following steps:

[0037] A. Prepare the undisturbed soil and place the soil to be measured into undisturbed soil pillars 5 and place them in the inner sealed tank 3. The height of the undisturbed soil pillars is 110mm. According to the height of the soil pillars, determine the nitrogen emission flux F N In the calculation formula, the gas volume V of the inner sealed tank 3 is 1.14L, and the inner rubber sealing cover 1 made of butyl rubber is used to seal the inner sealed tank 3, because the butyl rubber has low air permeability and goo...

specific Embodiment 3

[0043] Specific embodiment 3, when the culture starts, the nitrogen concentration C in the inner sealed tank 3 2 100μg L -1 , Nitrogen concentration C in inner sealed tank 3 after cultivation 1 133.3μg L -1 , The gas volume of the inner sealed tank 3 is 2.28L, and the soil column area A is 0.038m 2 , When the incubation time T is 2h, the method of using the gas emission measuring device to measure the trace nitrogen emission flux includes the following steps:

[0044] A. Prepare the undisturbed soil and place the soil to be measured into undisturbed soil pillars 5 and place them in the inner sealed tank 3. The height of the undisturbed soil pillars is 100mm. According to the height of the soil pillars, the nitrogen emission flux F N In the calculation formula, the gas volume V of the inner sealed tank 3 is 2.28L, and the inner rubber sealing cover 1 made of butyl rubber is used to seal the inner sealed tank 3, because the butyl rubber has low air permeability and good air tightness....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com