A Soft Measurement Method of Freeness in High Consistency Refining System

A high-consistency refining and soft-measurement technology, applied in paper testing, material inspection, etc., can solve problems such as low precision, poor timeliness of off-line manual measurement, and inability to directly measure freeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

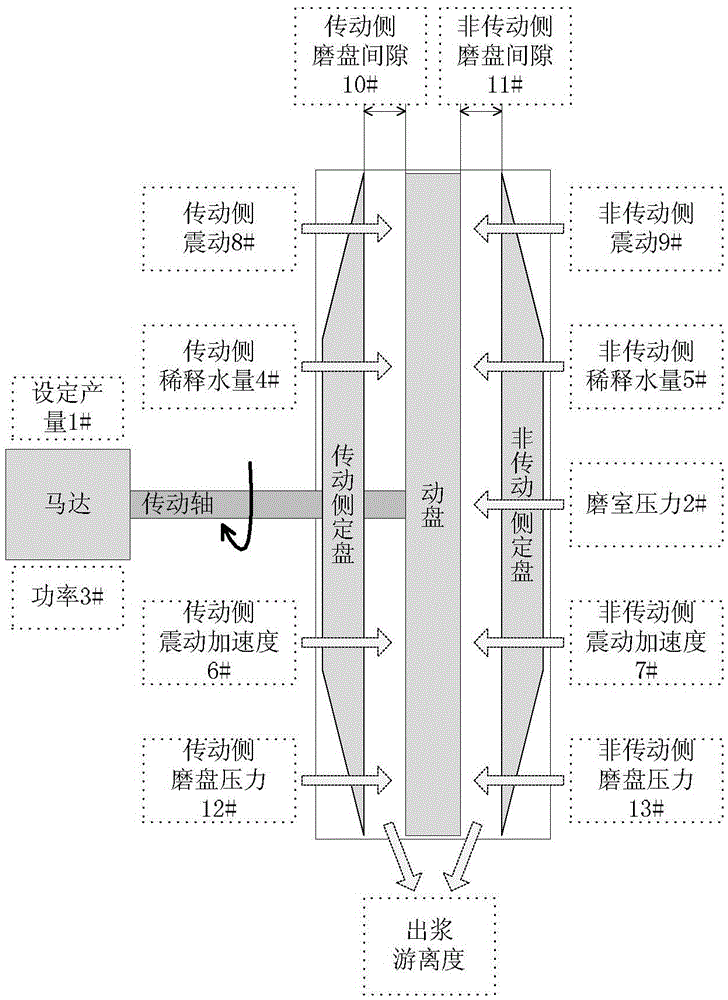

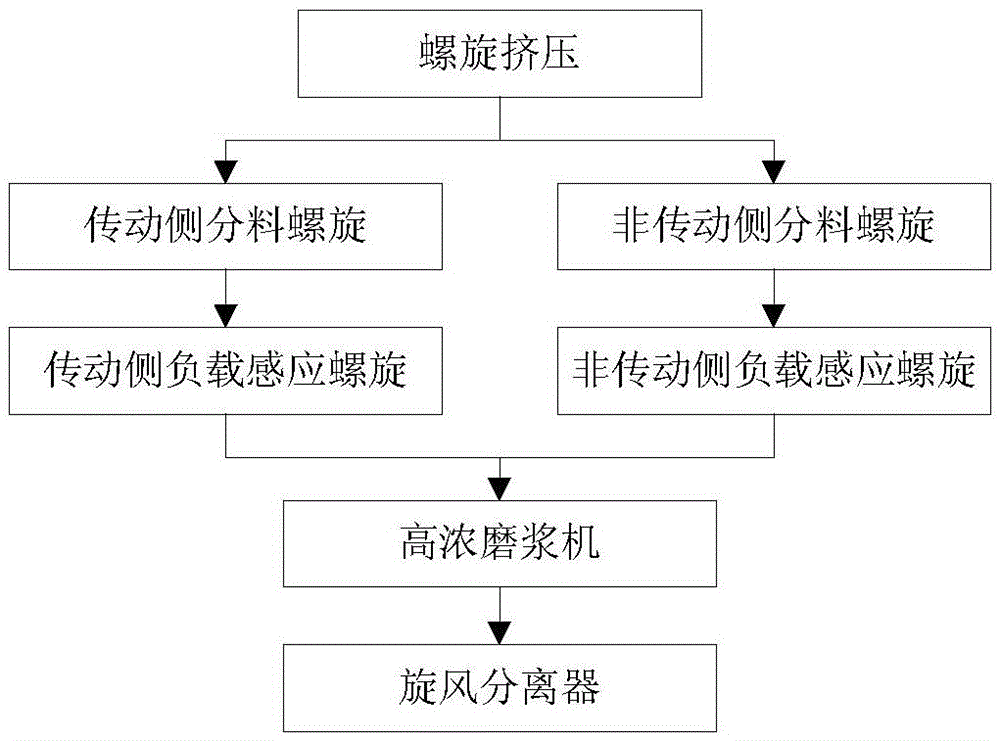

[0087] like figure 1 As shown, the three-disc refiner of the high-consistency refining system consists of a fixed disc with a double-tooth surface structure in the middle and two fixed discs on both sides to form a double-chamber structure. The three-disc refiner runs stably at high speed, and there will be no problems such as deflection of the moving disk. Without increasing the speed and diameter of the grinding disk, the area of the grinding disk is doubled, which has the advantages of increasing output, improving refining quality, Convenient heat recovery and other advantages.

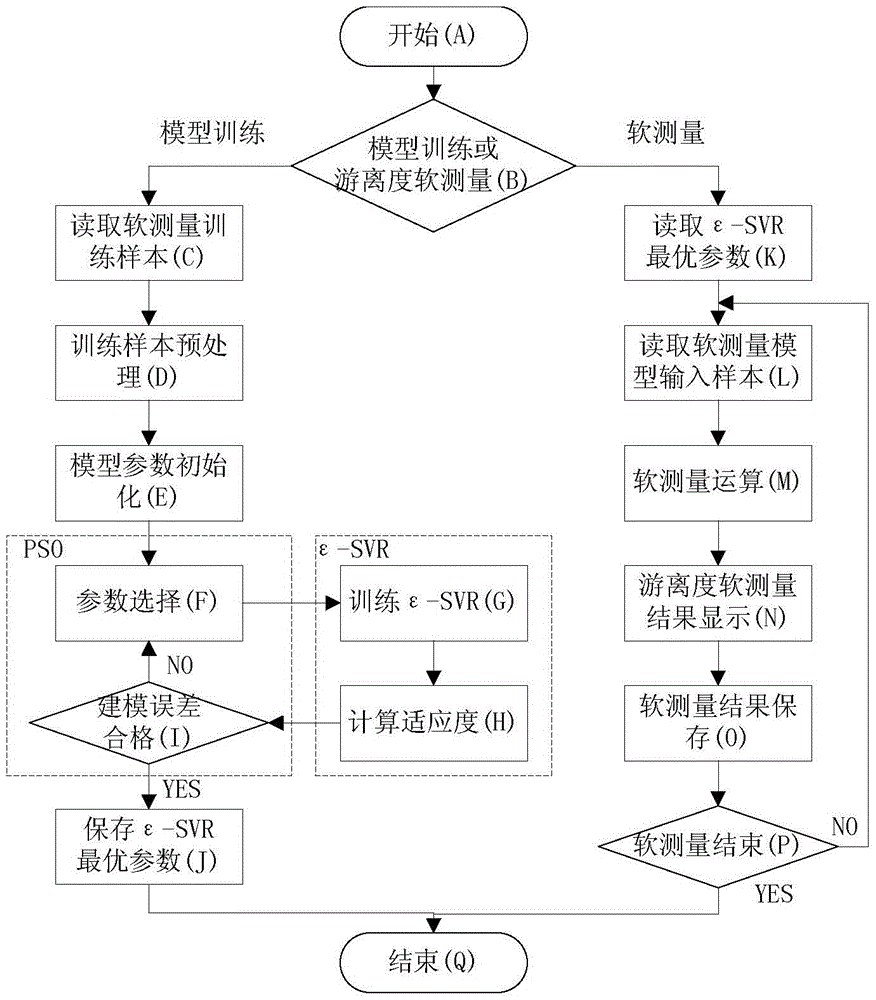

[0088] The invention provides a soft measurement method for the freeness of a three-disc refiner in a high-consistency refining system. The method can realize the real-time measurement of the pulp freeness of the high-consistency refiner, improve the efficiency and accuracy of manual measurement, and provide technical support for industrial real-time control and energy saving and consumption red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com