Soft measurement method for cooling water flow of condenser

A cooling water flow and condenser technology, which is used in measuring devices, instruments, electrical digital data processing, etc., can solve the problem that the condenser cooling water flow cannot be accurately measured online, the condenser cooling water pipe diameter is thick, and the flow To avoid abnormal operation accidents, improve operation reliability, and avoid accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

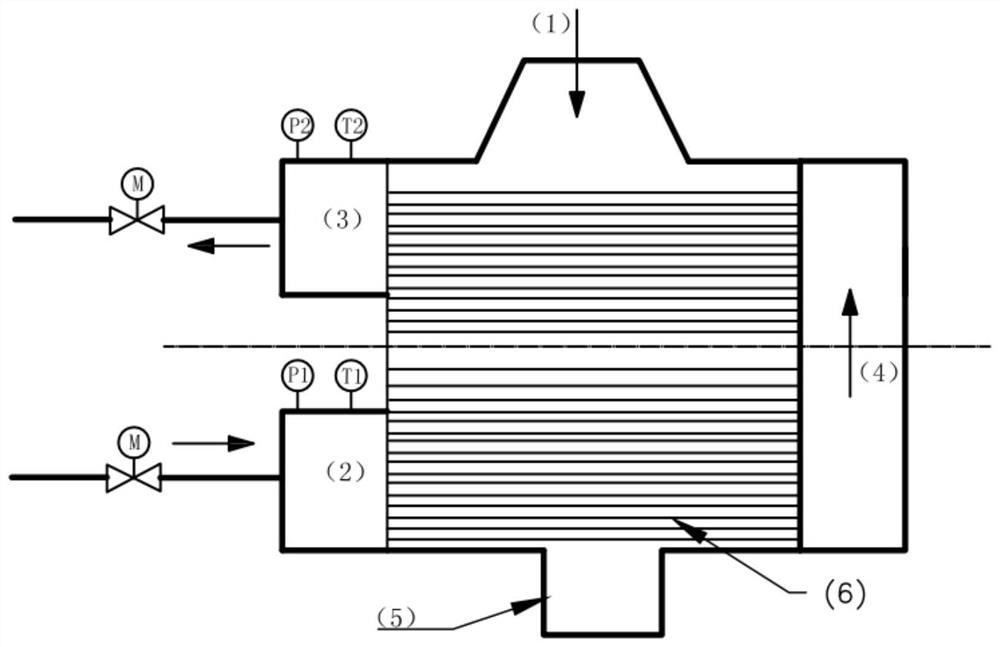

[0034] The invention provides a soft measurement method for condenser cooling water flow, and the measurement method comprises the following steps:

[0035] Step S1: Collect the real-time operation data of the DCS system of the turbo-generator set. The real-time operating data include the operating parameters and main data of the turbo-generator set, provide actual operating parameters for soft flow measurement, and analyze the influence of the cooling water flow of the condenser through the parameters factor;

[0036] Step S2: Perform statistics and analysis on the collected data to ensure that the parameters are accurate and there are no bad points, and prevent data distortion from causing errors in calculation results;

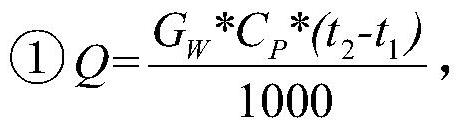

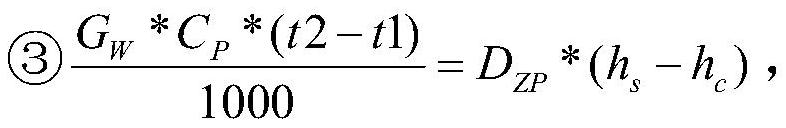

[0037] Step S3: According to the heat transfer balance principle of the cold and hot ends of the condenser, the internal heat transfer model of the condenser is established;

[0038] Step S4: Calculate the condenser cooling water flow rate based on the con...

Embodiment 2

[0040] The invention provides a soft measurement method for condenser cooling water flow, and the measurement method comprises the following steps:

[0041] Step S1: Collect the real-time operation data of the DCS system of the turbo-generator set. The real-time operating data include the operating parameters and main data of the turbo-generator set, provide actual operating parameters for soft flow measurement, and analyze the influence of the cooling water flow of the condenser through the parameters factor;

[0042] The collected data are shown in Table 1:

[0043] serial number parameter name unit symbol 1. load MW P 2. Condenser inlet cooling water temperature ℃ t 1

3. Condenser outlet cooling water temperature ℃ t 2

4. tide level m h 5. Condenser inlet cooling water pressure kPa p 1

6. Condenser outlet cooling water pressure kPa p 2

7. Condensate flow t / h G n

8. Condensate su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com