Design device and method for vacuum pressure impregnation product

A technology of vacuum pressure impregnation and product design, which is applied in calculation, special data processing applications, instruments, etc. It can solve the problems of small size of VPI reactor, large output, inability to improve design efficiency and optimize calculation, etc., to achieve accurate design, Strong pertinence and fast computing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand and understand, the present invention will be further described below in conjunction with specific embodiments.

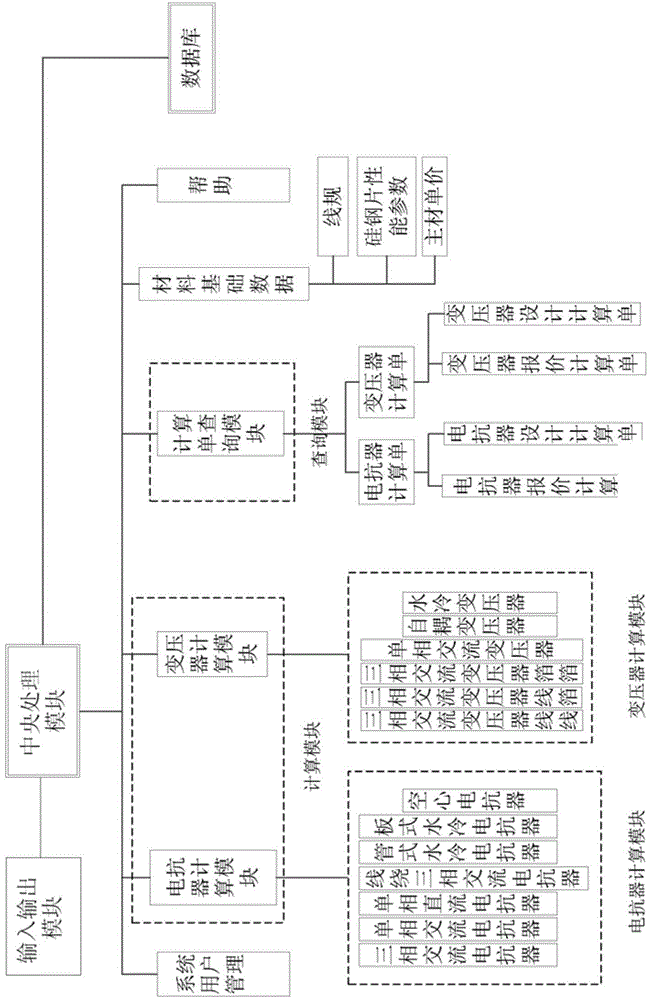

[0028] see figure 1 , is a schematic diagram of the module structure of the VPI product design device, including an input and output module for inputting user-selected parameters and outputting design results, a central processing module for processing data and selection, and a calculation module for calculating reactor or transformer parameters , a query module for calculating a single query, a material basic database and an external database for reactor or transformer material selection.

[0029] Among them, the material basic data module stores information such as the wire gauge required by the product, the performance parameters of the silicon steel sheet, and the unit price of the main material, which can be viewed by the user,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com