LED lamp design verification method and LED lamp design verification method application to externally-hung lamp or headlamp

A LED lamp, design verification technology, applied in special data processing applications, calculations, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

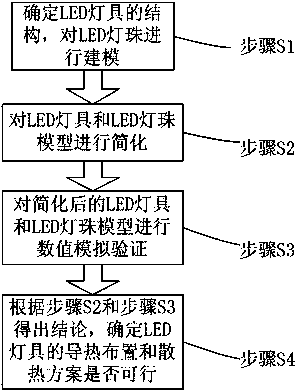

[0070] Example 1 Design and Numerical Simulation Verification of External LED Car Retrofit Lamp

[0071] Step S1: Determine the structure of the LED lamp: such as Figure 2-4 Shown is the structural diagram of the plug-in LED car modified lamp designed and determined by CAD software, the imitation lumen lamp bead on the middle substrate of the lamp, and the COB package (chip On board) lamp bead at the bottom of the lamp;

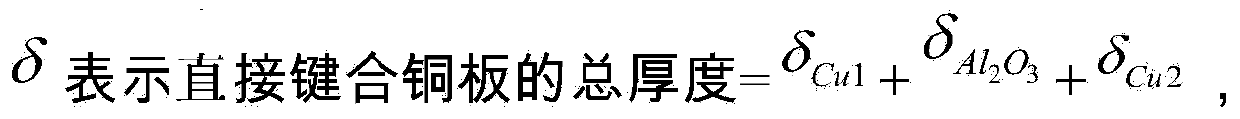

[0072]Modeling of LED lamps and LED lamp beads: 1. The high-power imitation lumen lamp beads are welded on the aluminum-based printed circuit board (Metal Core Printed Circuit Board, MCPCB) inside the car lamp, and are located in the external LED car modification lamp. The middle part has a heating power of 7W and is packaged in a heat-sinking SMT (Surface Mount Technology). The structure of the lamp bead is as follows: Figure 5 As shown, the material layers, thickness and thermal conductivity of the lamp bead are shown in Table 1; 2. The COB package high-...

Embodiment 2

[0092] Embodiment 2 is to the design and numerical simulation verification of replaceable LED headlights

[0093] Step S1: Determine the structure of the LED lamp, and model the LED lamp and LED lamp beads: such as Figure 7-9 As shown, the replaceable LED headlights with vertically arranged fins, the replaceable LED headlights with horizontally arranged fins, and the arrangement of lamp beads on the replaceable lamp substrate are designed and determined by CAD software. Structural diagram; the replaceable LED headlight adopts a 1.6mm*1.6mm high-power lamp bead array, and the thermal resistance of each lamp bead is about 0.4C / W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heating power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com