Fixture assembly sequence planning method based on particle swarm optimization algorithm

A technology of assembly sequence planning and particle swarm optimization algorithm, which is applied in computing, special data processing applications, instruments, etc., can solve the problem that particle swarm optimization algorithm cannot assemble sequences, achieve strong global convergence ability and robustness, avoid genetic operations, Effects that are easy to implement and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

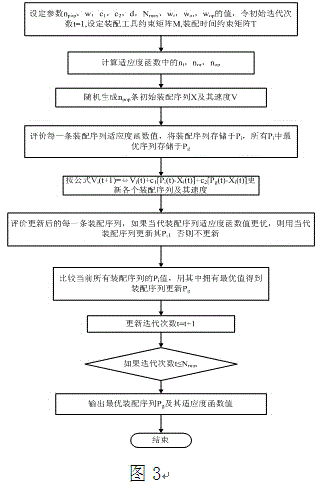

[0026] The specific example is as follows, assuming that a specific fixture needs to complete the time required for each assembly process and the required assembly tools, this program takes the shortest completion time of all machines as the optimization goal to optimize the problem, and its optimization model is

[0027]

[0028] In the formula: M J is the optimal assembly sequence scheme; T E is the processing end time of each machine for each assembly scheme.

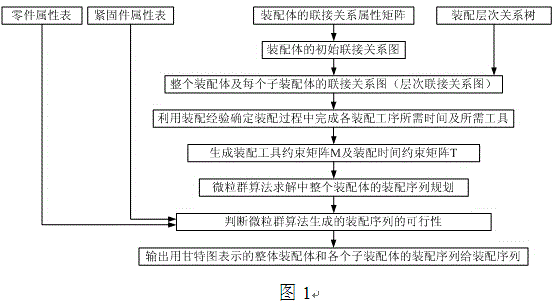

[0029] refer to figure 1 , a fixture assembly sequence planning method based on particle swarm optimization algorithm, comprising the following steps: including the following steps:

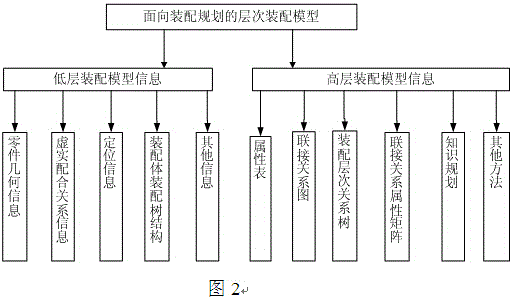

[0030] In the first step, use the figure 2 The hierarchical assembly model information diagram shown shows the inherent and implicit constraint relationship between the parts in each assembly, and adopts a hierarchical assembly model oriented to assembly planning to fully represent the requirements required in the assembly sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com