Direct-current generator

A technology of DC generators and housings, which is applied in the direction of electrical components, electromechanical devices, and electric components, and can solve problems such as large voltage ripples of three-phase DC generators, unfavorable products widely used, and increased production costs of products, and achieve voltage The effects of small ripple, high reliability, and easy installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage. The same reference numerals are used to denote the same components in the respective drawings, and thus the configurations of the same components will not be described repeatedly.

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

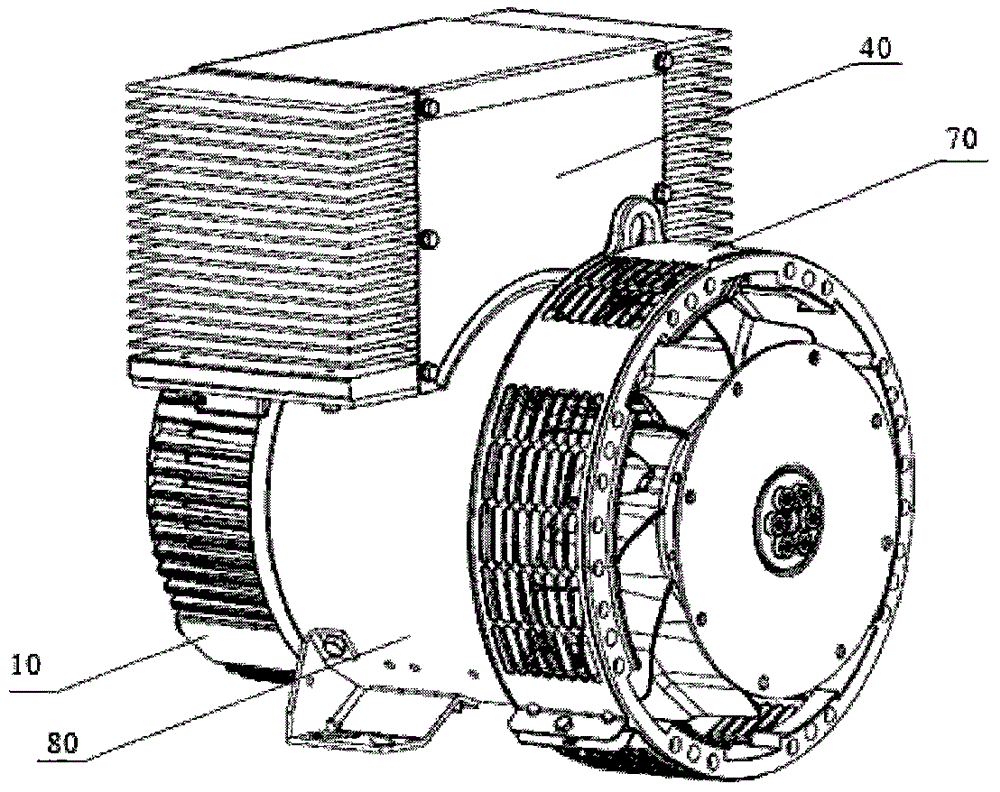

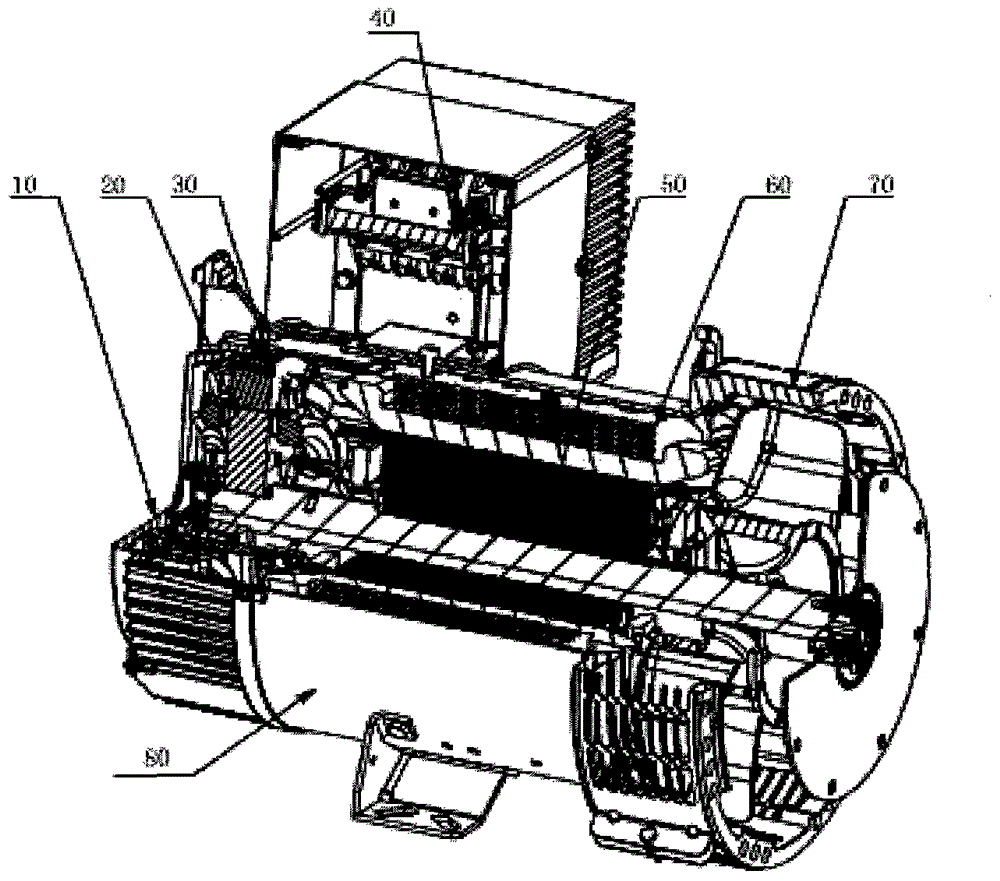

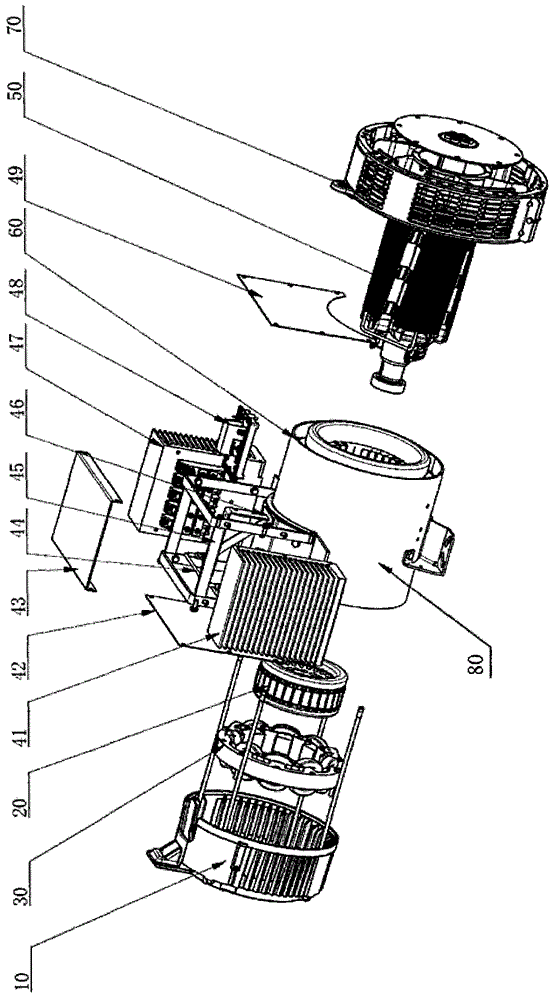

[0026] Figure 1-3 A direct current generator provided by the present invention is shown. as the picture shows, figure 1 It is a perspective view of a direct current generator of one of the embodiments of the present invention, figure 2 For such figure 1 The partial cross-sectional perspective view of the DC generator shown, wherein the DC generator includes a first end cover assembly 10, a second end cover assembly 70, a casing assembly 80, a main rotor 50, a main stator 60, a terminal assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com