Martensitic stainless steel and method for manufacturing same

A manufacturing method and stainless steel technology, applied in martensitic stainless steel and its manufacturing field, can solve problems such as being unsuitable for knives, and achieve the effect of excellent quality of the blade edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

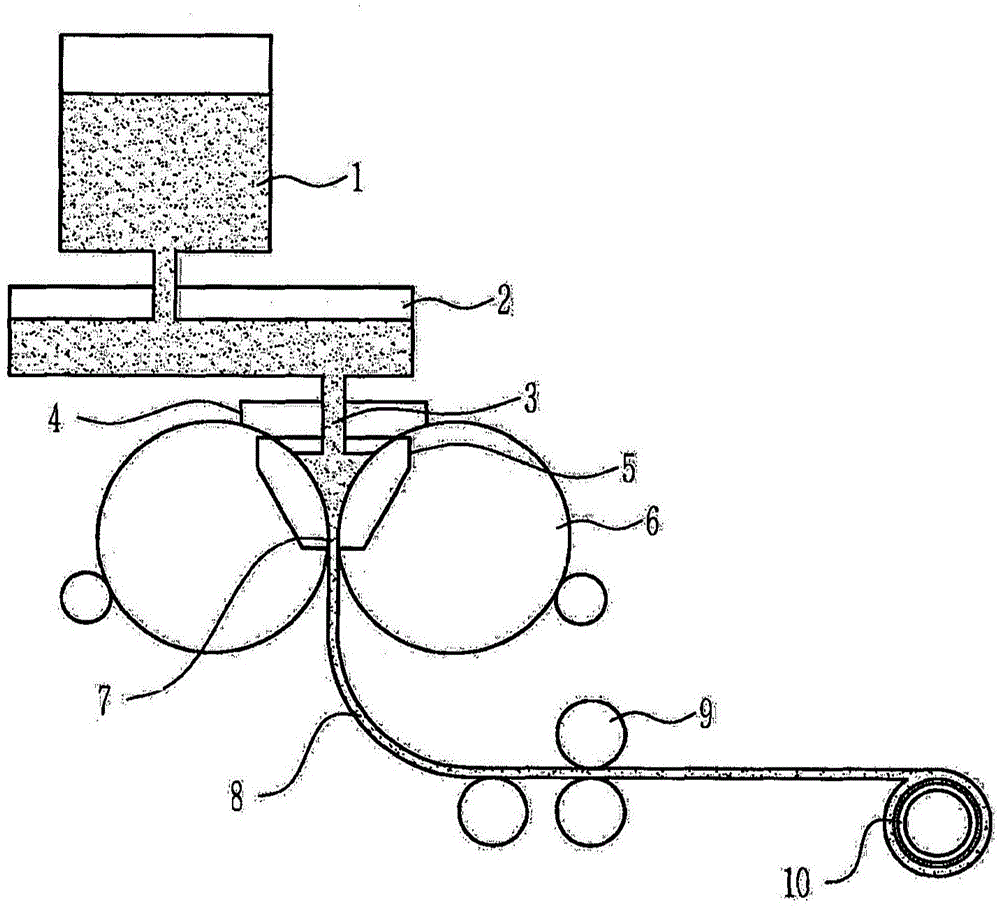

Method used

Image

Examples

Embodiment

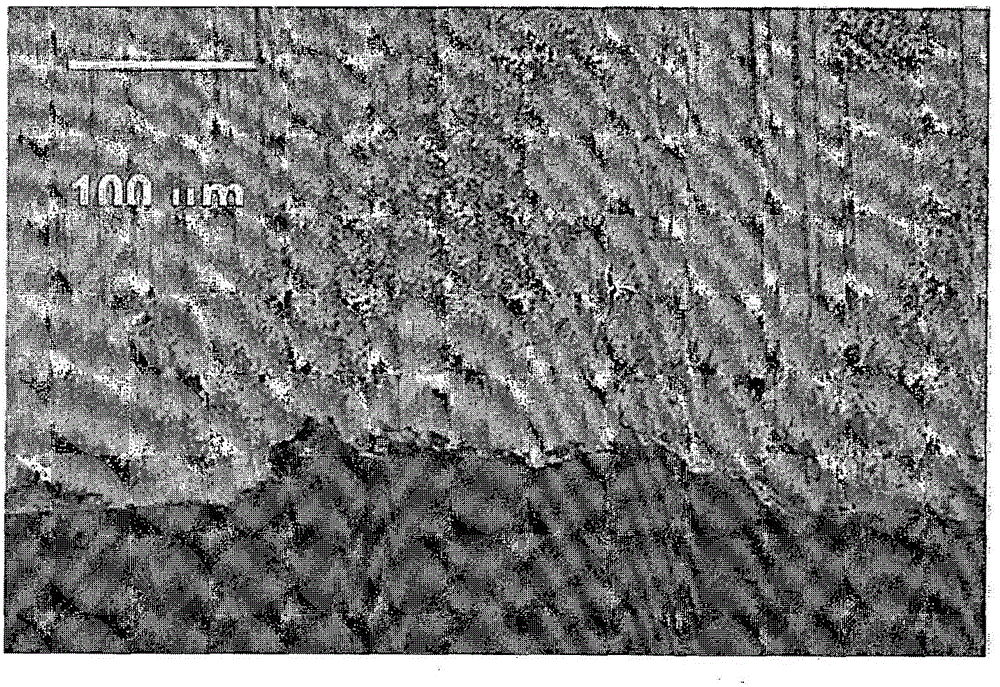

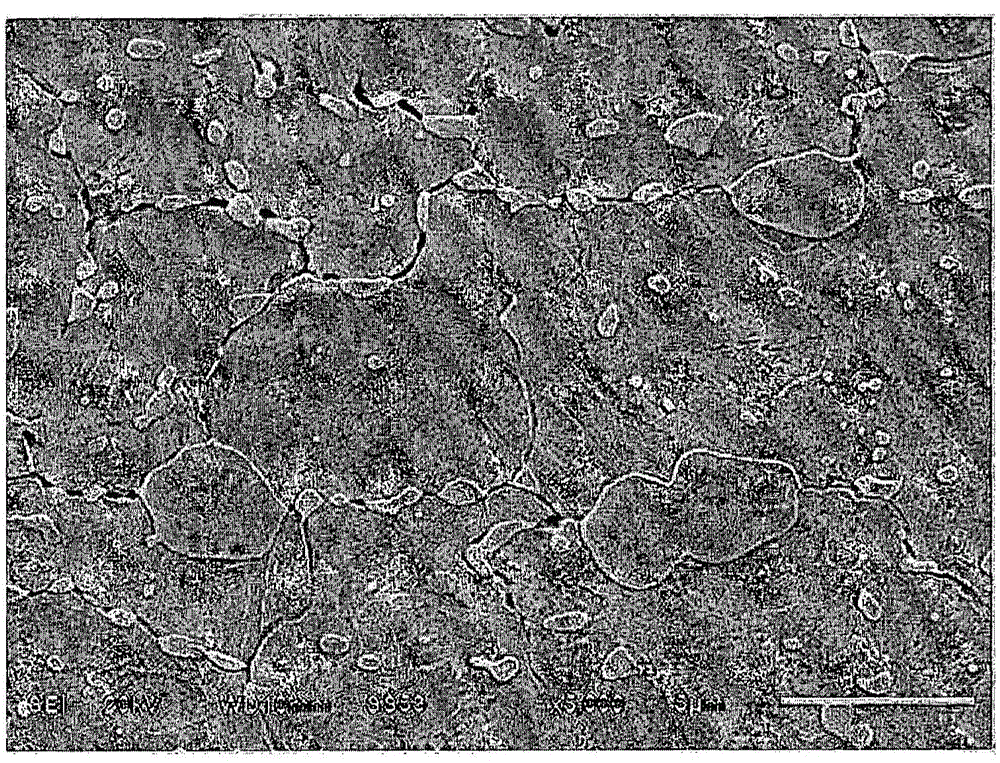

[0069] Hereinafter, examples of the present invention will be described. In Examples related to the present invention, microstructural properties of hot-rolled annealed sheets produced by a conventional continuous casting method and steel produced by a strip continuous casting method as an example of a rapid cooling casting method were compared.

[0070] Table 1 shows the composition of the steel produced by the ingot casting method and the strip casting method. First, in the comparative example of the present invention, 40 kg of a vacuum induction melting steel ingot having a thickness of 140 mm was produced by applying the conventional ingot casting method. This is shown in Table 1 as Comparative Example 1. Then, for hot rolling, the steel ingot was reheated at a temperature of 1250° C. in a heating furnace in an inert atmosphere, maintained at this temperature for 3 hours, and finally hot rolled to a thickness of 2 mm. In addition, steel with various components including ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com