A kind of beneficiation method of mechanically demagnesizing collophosite with external medium

A beneficiation method and a technology for colloidal phosphate rock, applied in flotation, solid separation and other directions, can solve the problem of increased beneficiation cost, etc., and achieve the effects of low MgO content, low comprehensive cost and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

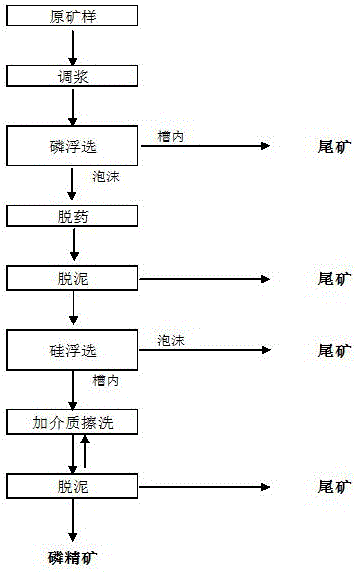

Image

Examples

Embodiment 1

[0023] Embodiment 1, a kind of beneficiation method of mechanically demagnesizing processing collophosite with external medium, its steps are as follows:

[0024] (1) Put the crushed silicon-calcium colloidal phosphate rock in the flotation tank, add water to adjust the slurry to a concentration of 60%, and add phosphate mineral flotation regulator and collector to it respectively Slurry is carried out, and the material after pulping is added with water to a pulp concentration of 25% and enters the positive flotation system for positive flotation of phosphate minerals. The resulting foam product is positive flotation concentrate, and the product in the tank is positive flotation tailings; The flotation adjustment agent comprises pH regulator is sodium carbonate and depressant water glass, the consumption of sodium carbonate is 0.5kg / t raw ore, the consumption of water glass is 0.5kg / t raw ore, and described collector comprises fatty acid soap and Auxiliary collector fuel oil, ...

Embodiment 2

[0027] Embodiment 2, a kind of beneficiation method of mechanically demagnesizing collophosite with external medium, its steps are as follows:

[0028] (1) Put the crushed silicon-calcium colloidal phosphate rock in the flotation tank, add water to adjust the pulp to a concentration of 80%, and add phosphate mineral flotation regulator and collector to it respectively Slurry is carried out, and the material after the slurry is added with water to a pulp concentration of 40% and enters the positive flotation system for positive flotation of phosphate minerals. The resulting foam product is positive flotation concentrate, and the product in the tank is positive flotation tailings; The flotation adjustment agent comprises pH regulator and is sodium carbonate and depressant water glass, and the consumption of sodium carbonate is 1.5kg / t raw ore, and the consumption of water glass is 1.5kg / t raw ore, and described collector comprises fatty acid soap and Auxiliary collector fuel oil...

Embodiment 3

[0031] Embodiment 3, a kind of beneficiation method of mechanically demagnesizing collophosite with external medium, its steps are as follows:

[0032] (1) Put the crushed silicon-calcium colloidal phosphate rock in the flotation tank, add water to adjust the slurry to a concentration of 70%, and add phosphate mineral flotation regulator and collector to it respectively Slurry is carried out, and the material after slurry is added with water to a pulp concentration of 30% and enters a positive flotation system for positive flotation of phosphate minerals. The resulting foam product is positive flotation concentrate, and the product in the tank is positive flotation tailings; The flotation adjustment agent comprises pH regulator as sodium carbonate and depressant water glass, the consumption of sodium carbonate is 1kg / t raw ore, the consumption of water glass is 1kg / t raw ore, and described collector comprises fatty acid soap and auxiliary collection The dosage of absorbent fue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com