Reshaping method for barrel with diameter greater than 1 meter

A shape calibration and cylinder technology, applied in the field of machining, can solve the problems of bumping the cylinder, difficulty in observation and adjustment, and heavy weight of large calibration tooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

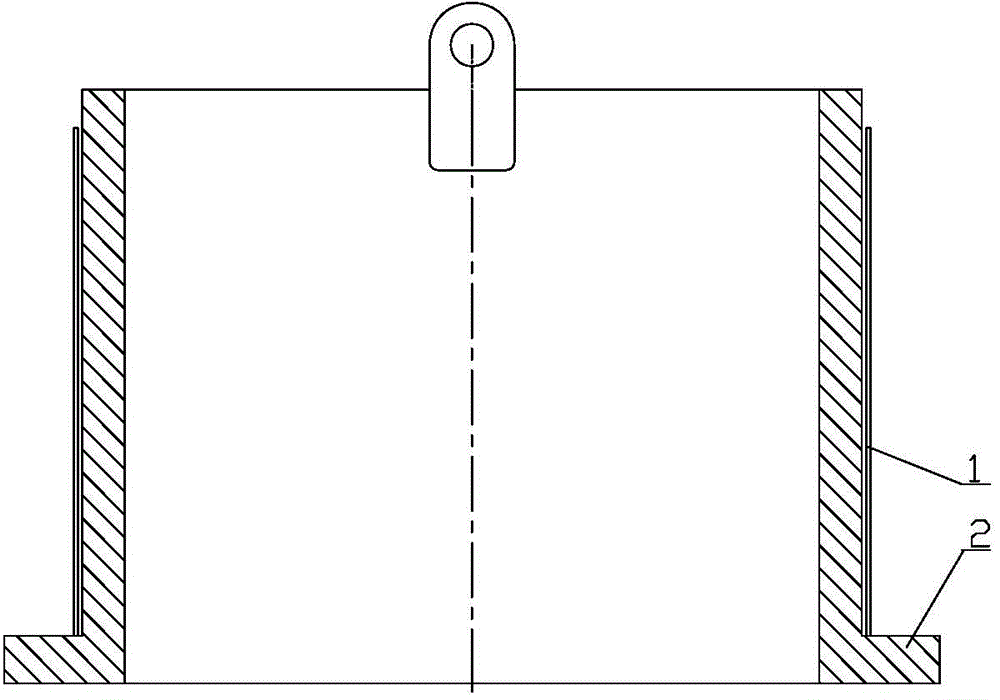

[0027] This embodiment is a method for improving the precision of forming a large cylindrical workpiece. The material of the formed workpiece is various carbon steels and various alloy steels. The outer diameter of the cylindrical body is φ1000-φ3000mm and the wall thickness is 3-15mm. The material of the bulging mandrel is made of stainless steel and heat-resistant stainless steel, and its linear expansion coefficient must be greater than that of the cylinder material. The equipment used in this method adopts a large-scale vertical heat treatment furnace or an annealing furnace, and its inner diameter is required to be more than 1000mm larger than the outer diameter of the cylinder.

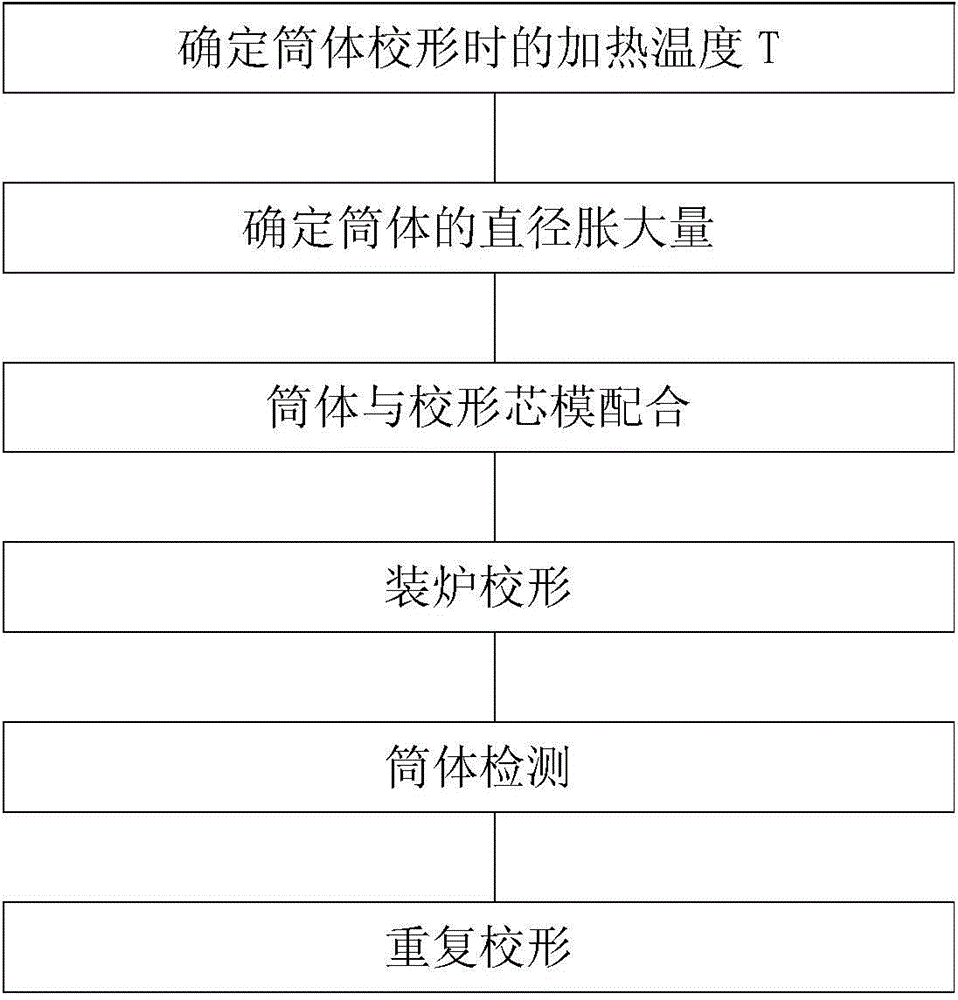

[0028] The concrete process of this embodiment is:

[0029] Step 1, determine the heating temperature T when the cylinder shape is corrected. The amount of cylinder expansion is determined according to formula (1):

[0030] Δd=αTd (1)

[0031] In the formula (1), α is the linear expansion coe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com