An electric caliper assembly assembly tool

A technology of assembly assembly and electric card, applied in assembly machines, manufacturing tools, workpiece clamping devices, etc., to achieve the effects of high precision, improved thread tightening accuracy, and large bolt axial preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

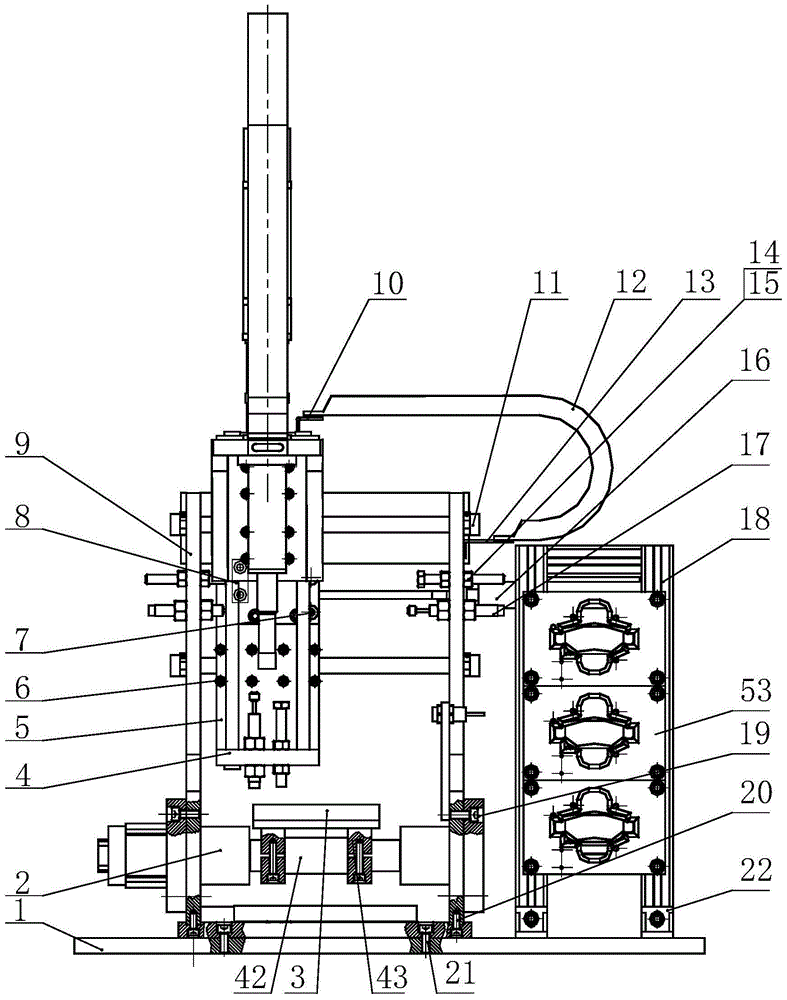

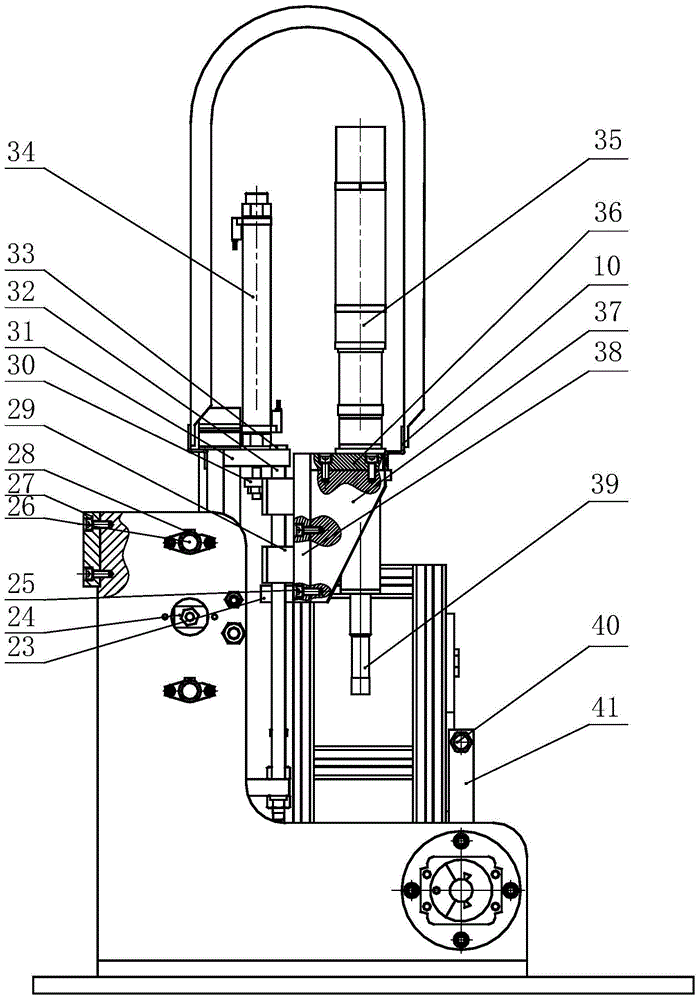

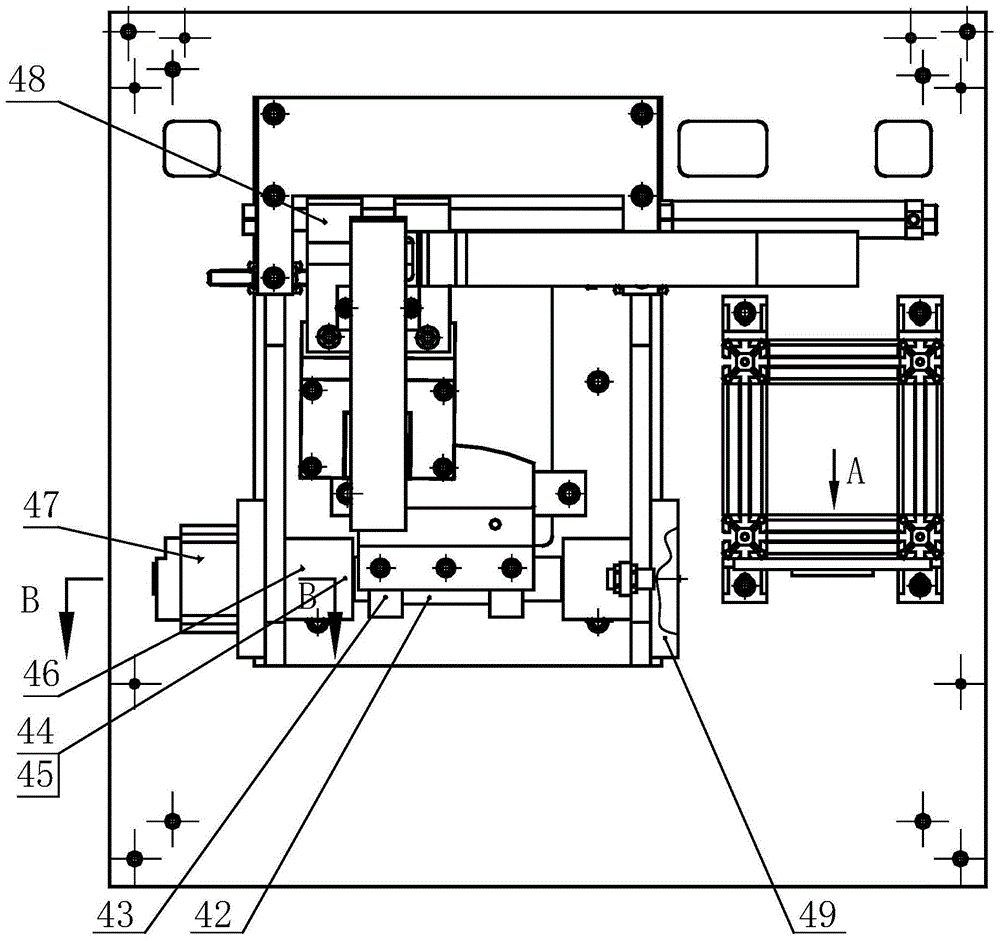

[0022] Such as Figure 1 to Figure 8 As shown, an electric caliper assembly assembly tooling includes a workbench 1, an automatic detection system, a clamping and rotating device, a two-degree-of-freedom adjusting device and a tightening device. The clamping and rotating device is installed on the left side of the workbench 1 On the upper end surface of the upper part, the two-degree-of-freedom adjustment device is installed on the clamping and rotating device, the tightening device is fixed on the two-degree-of-freedom adjustment device, and the automatic detection system is installed on the right upper end surface of the worktable 1 .

[0023] The clamping and rotating device includes a shaft coupling 2, a workpiece fixture 3, a vertical plate 9, a No. 1 screw 19, a No. 2 screw 20, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com