Machining measurement device of sealing ring for triple eccentric butterfly valve

A triple-eccentric butterfly valve, processing and measurement technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of large differences in measurement results, not particularly good sealing effect, short service life, etc., to achieve Eliminate human error and instability, avoid human factors and technical factors, and measure the effect of high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

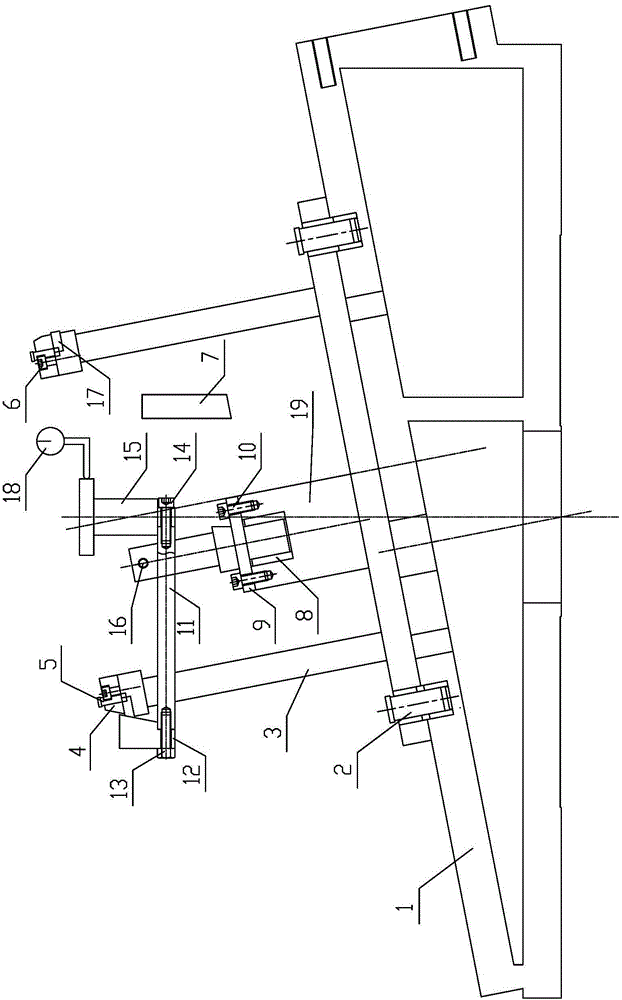

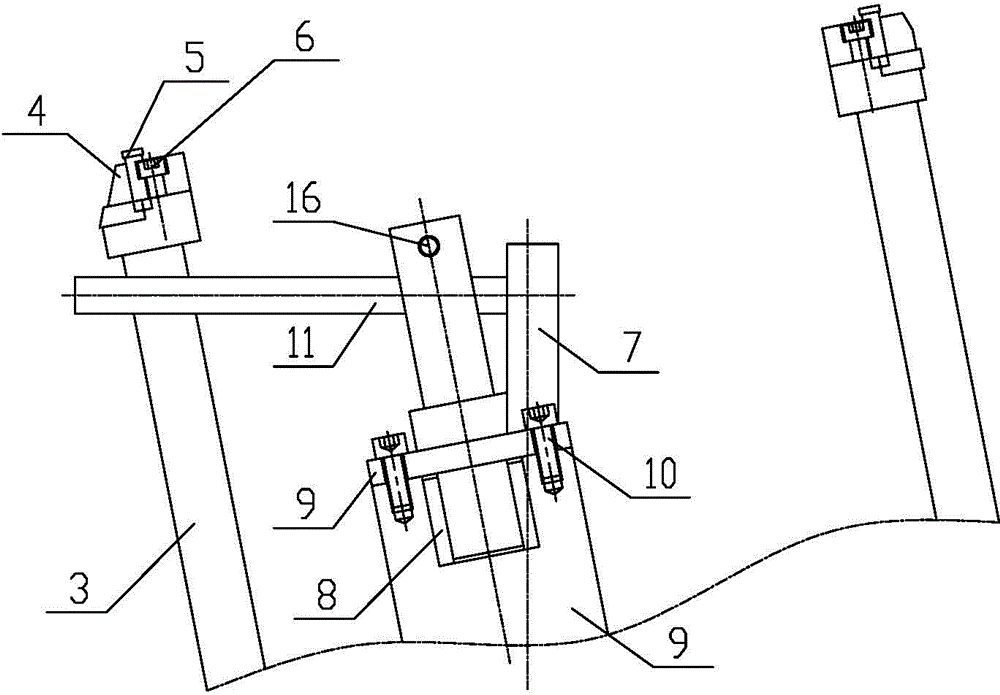

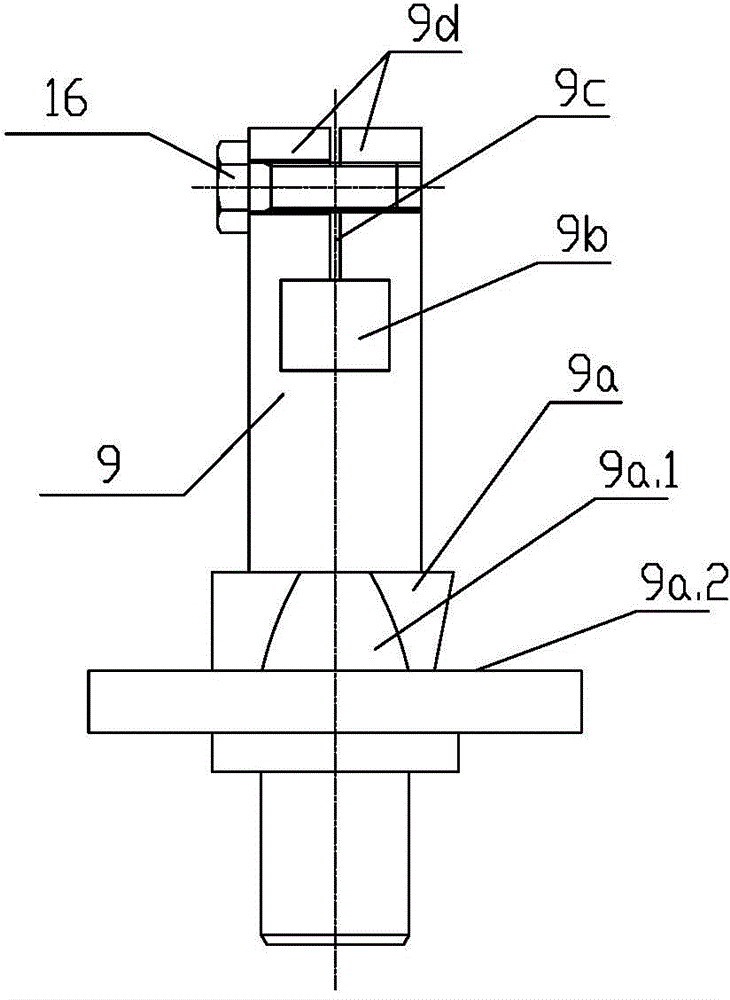

[0020] As shown in the figure: the processing and measuring device for the sealing ring of the triple eccentric butterfly valve in the embodiment is mainly composed of an inclined table 1, a positioning pin 2, a contour ring 3, a pressure ring 4, a sealing ring positioning pin 5, a pressure ring screw 6, a positioning Plate 7, measuring rod bearing 8, measuring rod 9, measuring rod positioning screw 10, measuring pin 11, cam 12, cam fixing bolt 13, wire dial mounting screw 14, wire dial 15, measuring pin fixing screw 16, Silk table 18 and mounting table 19 etc. are formed.

[0021] Such as Figure 1~Figure 4 As shown, the contour ring (3) is connected to the inclined surface of the inclined platform (1) through the positioning pin (2), and the outer circumference of the top of the contour ring (3) is provided with a workpiece groove, and the sealing ring (17) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com