Vacuum infusion and flow guide system and infusion and flow guide method for reinforcing plate of wind turbine blade

A technology for wind power generation blades and vacuum infusion, applied in the field of wind power generation, can solve problems such as uneven injection speed, influence on the strength of rib plates, hidden dangers, etc., and achieve high power generation requirements, reasonable structure design, and controllable flow speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

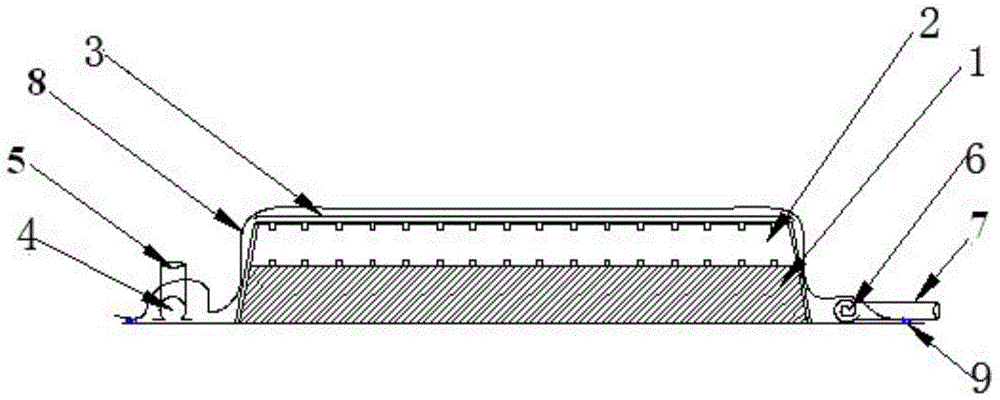

[0029] A method for vacuum infusion and diversion of ribs in wind power blades, comprising the following steps:

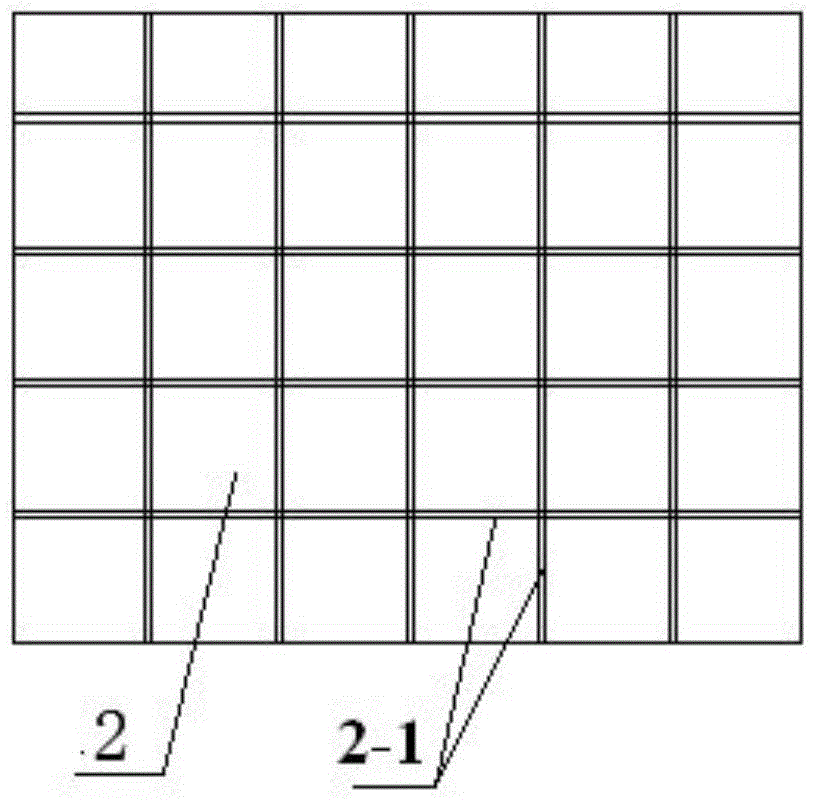

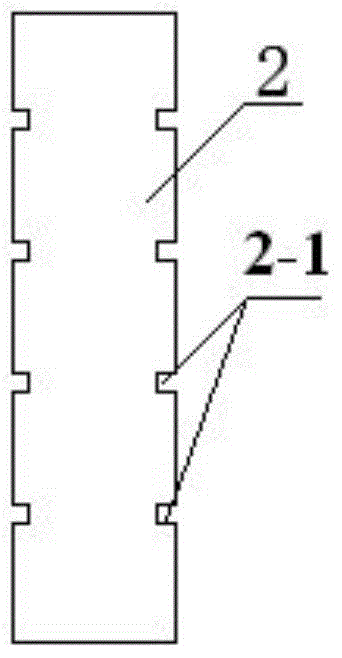

[0030] a. After cleaning the mold, paste the sealing strip (9) on the flange around the rib plate mold (1), and then follow the laying process to put the glass fiber inner skin, core material (2) and glass fiber outer skin 1. The diversion net (3) is laid on the rib plate mold (1) in turn. After the laying is completed, the diversion groove Ω pipe (4) is laid on the rib plate mold (1) side, and the diversion groove Ω pipe (4) ) at regular intervals to open the injection port (5), then lay the spiral pipe (6) on the opposite side of the rib plate mold (1), and connect the air outlet (7) with the spiral pipe (6); then use the vacuum film (8 ) sealing the diversion net (3), the diversion groove Ω tube (4) and the spiral tube (6) in a vacuum, and bonding and sealing with a sealing tape (9) to obtain a sealing system;

[0031] Then vacuumize to -0.098MPa~-0.1MPa throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com