Limiting sliding fixing device

A fixing device and limit slip technology, which is applied in the field of aerospace materials, can solve the problems of large deformation of the antenna array, excessive thermal stress, large bending or twisting of the antenna array, etc., and achieve the effect of increasing mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

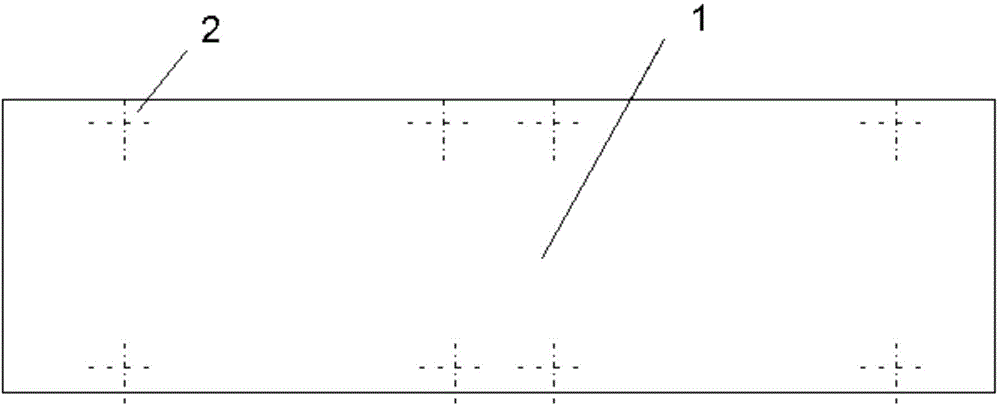

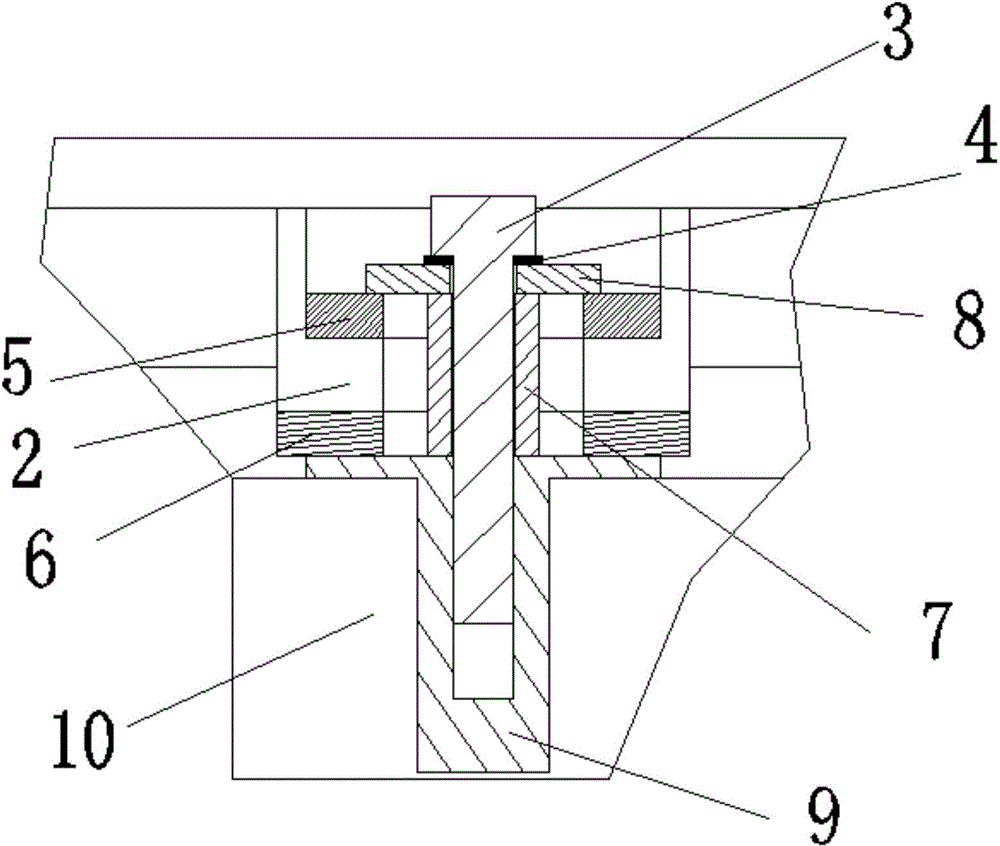

[0024] like figure 2 As shown, a limit slip fixing device is installed on the four mounting feet 2 outside the antenna front 1, and is used to fix the antenna front 1 on the bracket. The device includes: screws 3, screw washers 4. The first solid lubricating sheet 5, the second solid lubricating sheet 6, the sleeve 7, the transition gasket 8 and the embedded block 9; the first solid lubricating sheet 5 and the second solid lubricating sheet 6 pass through the countersunk head The screws are respectively fixed on the top and bottom of the mounting foot 2; the middle part of the first solid lubricating sheet 5, the second solid lubricating sheet 6 and the mounting angle 2 is provided with an oblong through hole of the same size for the sleeve 7 Inserted into the installation angle 2, the screw 3 is screwed into the threaded hole in the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com