Elevator bucket conveyor test device and method

A test device and feeder technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of low accuracy of solid flowmeter, difficult to achieve the purpose of the test, large error, etc., to achieve extended trouble-free Working time, optimized design, the effect of improving conveying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

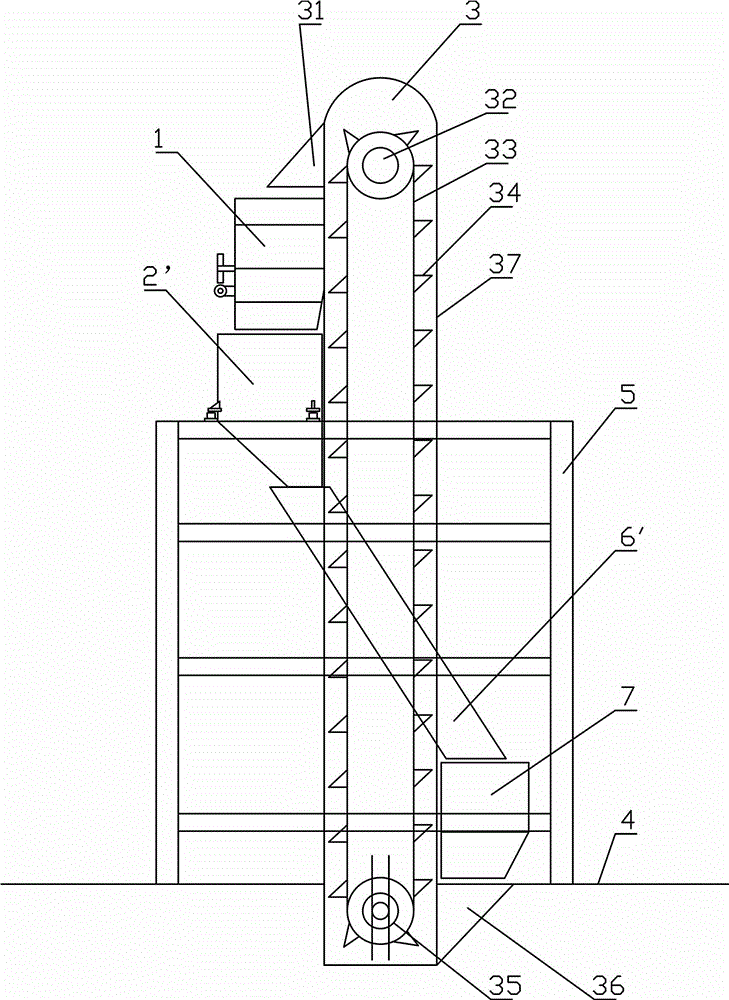

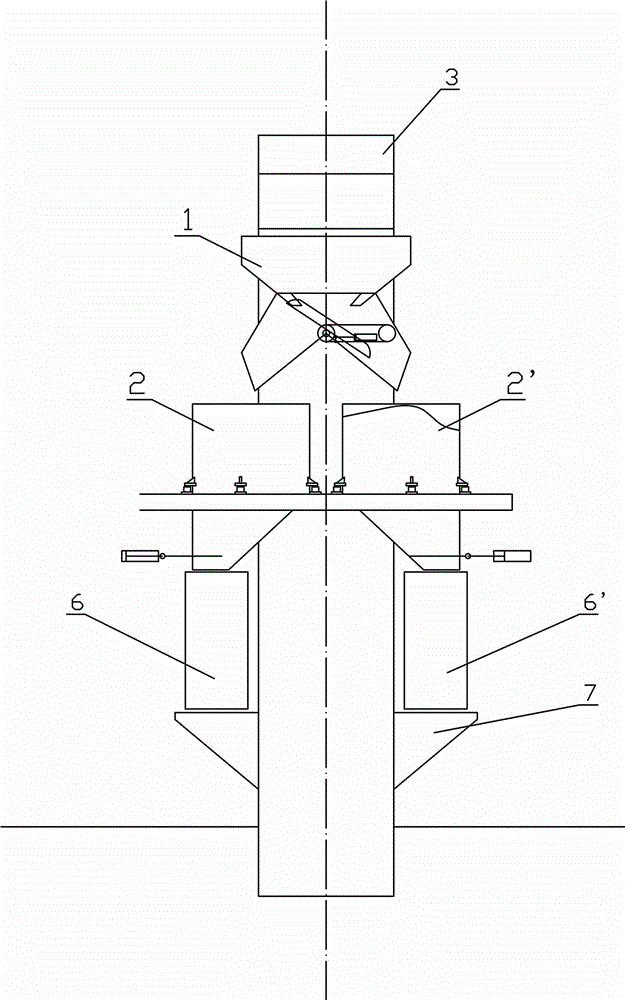

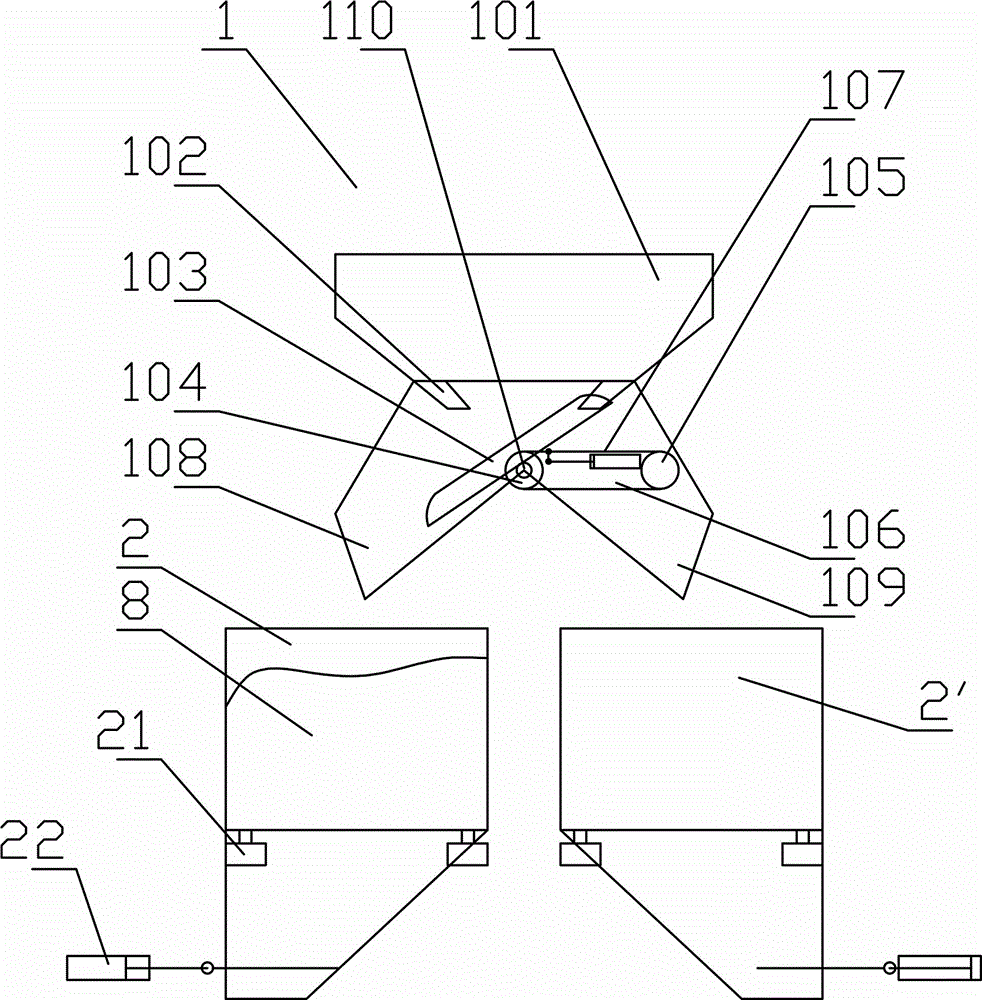

[0034] Such as Figure 1~5 Among them, a lifting bucket conveyor test device, a flow diversion device 1 is provided below the discharge port 31 of the lifting bucket conveyor 3, and the bottom of the flow separation device 1 is provided with a switchable first discharge port 108 and a second discharge port. port 109, a first weighing hopper 2 is provided below the first discharge port 108, and a second weighing hopper 2' is provided below the second discharge port 109;

[0035] The bottom of the first weighing hopper 2 is provided with a first circulation chute 6, the bottom of the second weighing hopper 2' is provided with a second circulation chute 6', and the bottom of the first circulation chute 6 and the second circulation chute 6' is provided with a storage tank. The hopper 7 and the storage hopper 7 are located above the feeding port 36 of the lifting bucket conveyor 3 .

[0036] preferred as Figure 2~4 Among them, the first weighing hopper 2 and the second weighing ...

Embodiment 2

[0049] On the basis of Example 1, such as figure 1 , 2 , 6. A method for carrying out a material delivery test using the above-mentioned lifting bucket conveyor test device, comprising the following steps:

[0050] 1. Switch the diverter device 1 to the first discharge port 108, and close the gate of the first weighing hopper 2, as image 3 shown in .

[0051] 2. The storage hopper 7 supplies material to the feeding port 36 of the lifting bucket conveyor 3, and the frequency conversion motor or hydraulic motor on the lifting bucket conveyor 3 starts feeding, and the start time t is set 0 , the material is discharged from the discharge port 31 of the lifting bucket conveyor 3 to the distribution device 1, and is discharged into the first weighing hopper 2 through the first discharge port 108, and the load cell 21 starts weighing; Before the sensor 21 is set, the weight including the entire first weighing hopper assembly is set to zero. This is convenient for later calculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com