Novel glass liquid melting method by means of submerged combustion with stable compensation

A technology of immersion combustion and molten glass, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as difficulty in practical application, high gas temperature, de-fire or tempering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

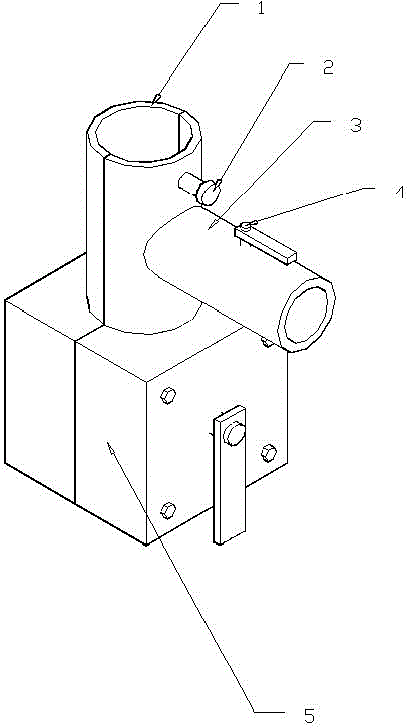

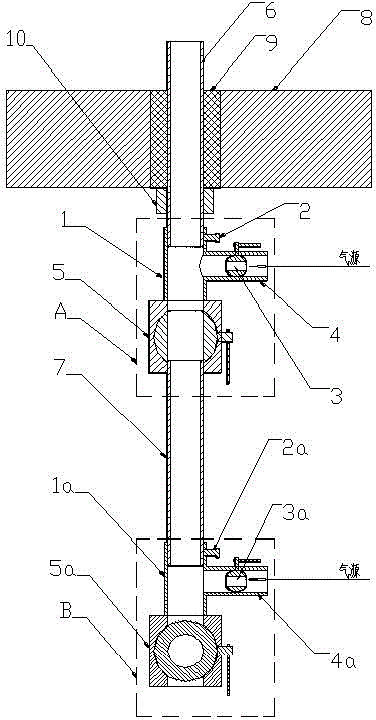

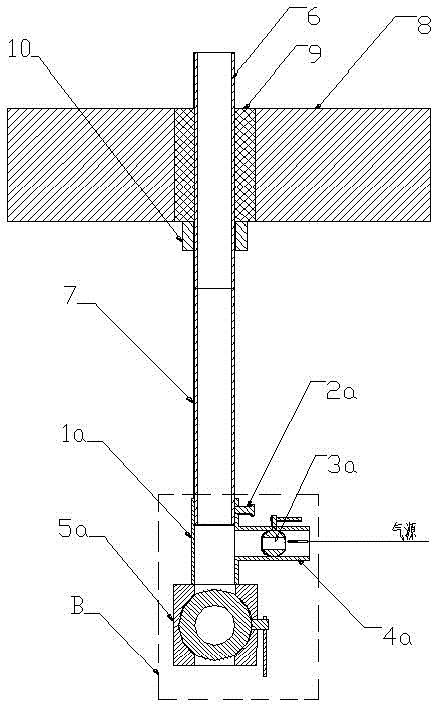

[0018] figure 1 , when connecting the gas nozzle (6) and the compensation pipe (7), first arrange the tee pipe (B) behind the tee pipe (A), and install the compensation pipe (7) from the bottom of the tee pipe (B) After insertion, close the delivery branch valve (5a) of the tee pipe (B), and temporarily position the compensation pipe (7) on the two delivery pipes of the tee pipe (B) and the tee pipe (A) with the set screw (2a). between the branch pipes (1a) and (1); then open the intake branch valve (3a) of the tee pipe (B) and the delivery branch pipe valve (5) of the tee pipe (A), and close the tee pipe (A) at the same time Air intake branch pipe valve (3); then push the tee pipe (B) and the compensation pipe (7) fixed on it to the bottom of the gas nozzle (6), and push the gas nozzle (6) and compensation pipe (7) Connect them by thread; then remove the three-way pipe (A); alternately advance to the kiln pool through the circulation of the three-way pipe (A) and the three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com