A low-carbon magnesia-carbon brick with non-oxide reinforced and toughened structure and its preparation method

A strengthening and toughening, non-oxide technology, applied in the field of refractory materials, can solve the problems of high cost of low-carbon magnesia-carbon bricks, difficulty in industrial production, and lower temperature of molten steel, so as to improve corrosion resistance, eliminate carburization, and enhance The effect of structural toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

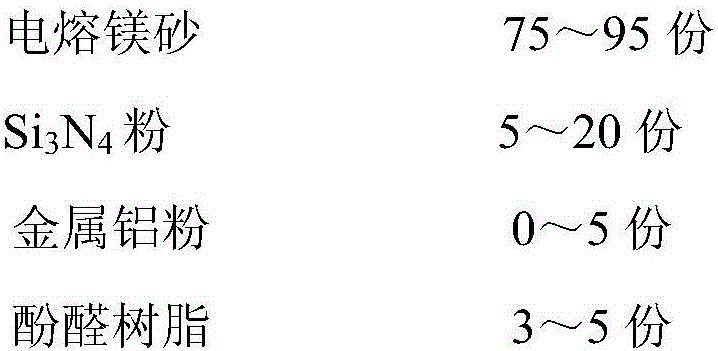

[0029] A kind of low-carbon magnesia-carbon brick with non-oxide reinforced and toughened structure according to the present invention is composed of the following raw materials in parts by weight:

[0030]

[0031]

[0032] Among them, the weight percentage of MgO content in fused magnesia is ≥97%, and the bulk density is ≥3.43g / cm 3 , particle size≤5mm;

[0033] The Si 3 N 4 The weight percentage of Si3N4 content in the powder is ≥97.5%, the weight percentage of impurity content is ≤2.5%, and the particle size is ≤0.088mm;

[0034] The Al content of the metal aluminum powder is greater than 99% by weight, and the particle size is ≤45 μm.

[0035] The phenolic resin used as a binder can be either thermosetting or thermoplastic.

[0036] Table 1 shows the weight percentage distribution data of the raw material components of each specific example, and the weight part data o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com